4-6. Verification After Repair

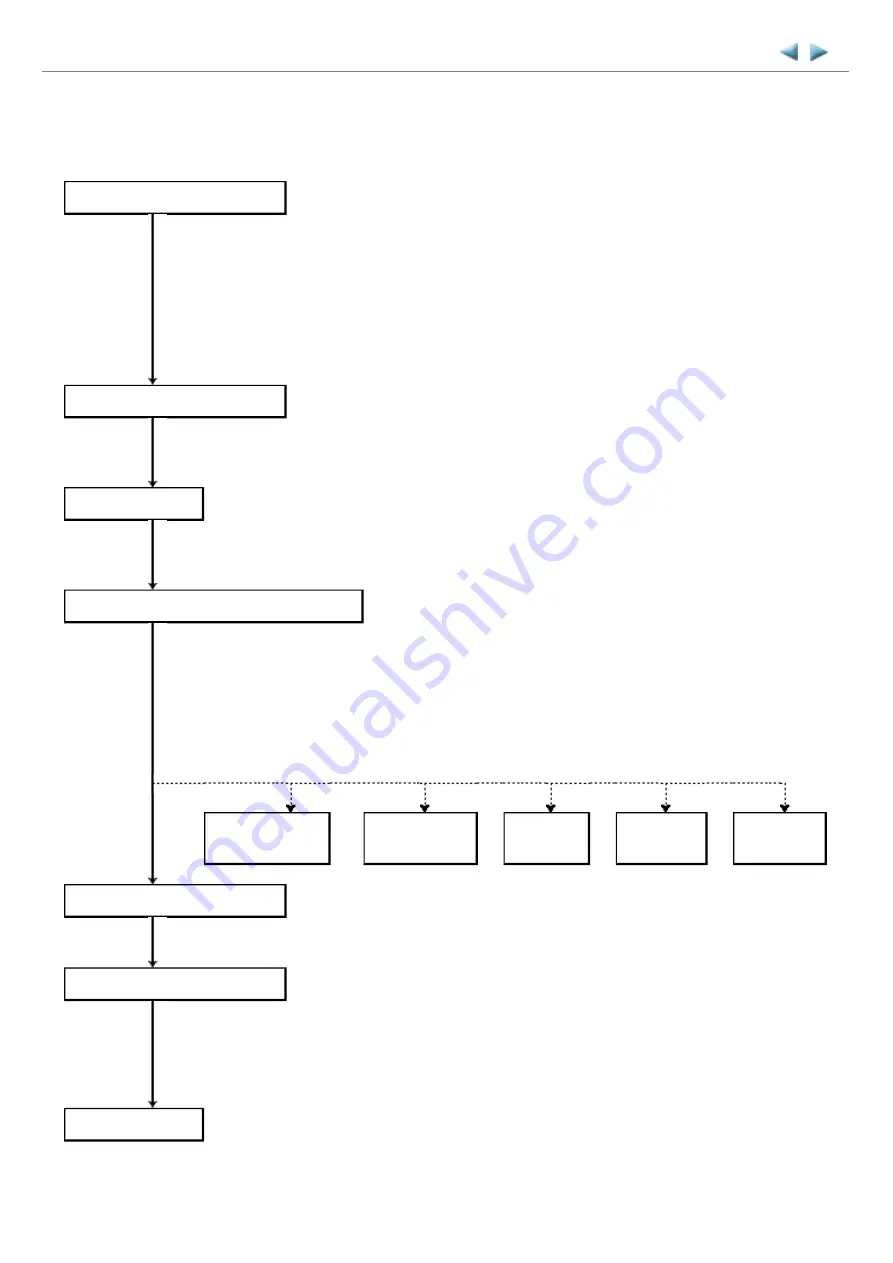

(1) Standard inspection flow

In each step below, confirm that printing is performed properly and the machine operates properly without any strange noise.

MX870

--- 4. ADJUSTMENT / SETTINGS

TABLE OF CONTENTS

EEPROM information print

<Check point>

- The information must be printed properly.

<Additional verification to be made> See

3-1. Major Replacement Parts

.

-

At logic board replacement

-

At ink absorber replacement

-

At platen unit or spur unit replacement

-

At operation panel or LCD replacement

- At wireless LAN board replacement

Nozzle check pattern print

<Check point>

- The pattern must be printed properly. (The pattern can be printed in the user mode or in the service

mode.)

Copy function

<Check point>

<Additional verification to be made> See

3-1. Major Replacement Parts

.

-

At document pressure sheet or scanner unit replacement

Communication with a connected computer

<Check point>

- Via USB connection to the computer, printing from the computer must be performed properly

(paper feeding from the rear tray and from the cassette respectively).

<Additional verification to be made>

- For repair of a specific problem, confirm the applicable specific function in the user mode.

PictBridge, IrDA communication, wired / wireless LAN, Bluetooth communication, Scan-to-Memory

function, Card Direct printing

PictBridge, IrDA

LAN / WLAN

Bluetooth

Scan-to-

Memory

Card Direct

Power-off in the service mode

<Check point>

- The paper lifting plate must be in the raised position.

External and internal appearance

<Check point>

- No grease, oil, or smearing on the timing slit strip film.

- No lifting of the platen ink absorber.

- No foreign material or dislocation of any part inside the printer.

- No damage or scratches that will affect the functionality.

Packaging

<Check point> See

5. MACHINE TRANSPORTATION

.

- The carriage must be locked in the home position.

60 / 63

Содержание PIXMA MX870 Series

Страница 8: ...5 63 ...

Страница 9: ...6 63 ...

Страница 31: ...8 Remove the main case no screws 28 63 ...

Страница 34: ...31 63 ...

Страница 35: ...4 Remove the LCD ass y no screws 5 Remove the panel board 11 screws 32 63 ...

Страница 39: ...2 Remove the PE sensor board 5 screws 36 63 ...

Страница 64: ... 2 Service test print Service test print sample unified inspection pattern print 61 63 ...

Страница 65: ... 3 Ink absorber counter value print Print sample 4 6 Verification After Repair 62 63 ...