Operator Manual

BB3002 Page 95

Initial issue: 05/08

Latest revision: 12/14

8 . MaInTenance

8 .1 Preventive maintenance

WaRnInG:

Risk of burns. Wear safety glasses and heat protective gloves !

Daily:

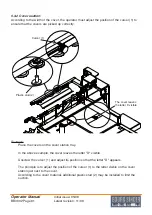

- carriage:

Check the condition of the jaws, remove any traces of glue. Use spray

cleaner 9195053.

- Glue gun:

Purge the system and clean the excess of glue by opening then closing the

gun to the maximum.

After switch off the machine and clean the gun with spray cleaner 9195053 and tools

supplied with the machine.

Apply grease 9195056 on gun openings and preventive protective liquid on gun

assembly.

-

cover clamp:

Check the state of the clamps and the black non-stick plate: remove any

traces of glue.

Preventive protection liquid9195051.

-

output unit:

Check that the baffle plates, guides are clean and remove any traces of glue.

-

external waste collector:

Shake the filter (cloth bag).

-

Glue Melter PUR c:

Check for cured glue (skin of surface). Remove it with tools

supplied with the machine.

Weekly:

-

General cleaning of the machine .

-

Milling:

Make sure there is no waste paper in the milling unit and the pipes.

- Glue gun:

Purge the system and clean the excess of glue by opening then closing the

gun to the maximum.

After switch off the machine and clean the gun with spray cleaner 9195053 and tools

supplied with the machine.

Apply grease 9195056 on gun openings and preventive protective liquid on gun

assembly.

-

Waste paper bin:

See whether the bag is full (see chapter

-

clean the grill of the glue fumes extractor

.

-

system purge

"7.2 Purging System Sequence", page 90).

aTTenTIon:

In the event of undunly long stops (from

5

* days), purge the gun and the

heating hose using special cleaner (

9195052

) and apply special grease

ND

402238

(

400

g), ND

78359

on gun (

250

g).

* Depending on adhesive type, how long adhesive was already under

temperature and humidity of environment.

Monthly:

-

cover loading:

Check the condition of the suction cups.

Once a year:

- Test the Tank pressure valve by turning the dry air controller up to 0.4 bar until heard

the gas escaping. If not call for technical ambiance.

Содержание BB3002 PUR

Страница 7: ...Operator Manual Page 7 Initial issue 05 08 Latest revision 11 08 Environmental compliance 141...

Страница 9: ...Operator Manual BB3002 Page 9 Initial issue 05 08 Latest revision 11 08 BB3002...

Страница 82: ...Operator Manual BB3002 Page 82 Initial issue 05 08 Latest revision 11 08 5 4 Not available...

Страница 103: ...Operator Manual BBL Page 103 Initial issue 09 13 Latest revision BBL...

Страница 120: ...Operator Manual BBC Page 120 Initial issue 09 13 Latest revision BBC...