Page 34

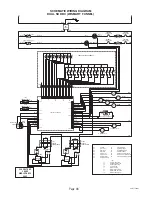

SERVICE TOOLS (cont.)

29877 121302

PROGRAMMING FUNCTIONS - LEVEL 2 (cont.)

2. Place a Soft Heat

®

server beneath each brew

funnel.

3. Press and hold the ® pad until the display reads

SET NEW RECIPES.

Release the ® pad. Continue

pressing and releasing the ® pad until

SERVICE

TOOLS

appears.

4. Press

YES

to run tests on various components and

outputs within the brewer. (Pressing

NO

will exit

this function and advance to the next function

screen.)

5. The display should read

TEST OUTPUTS.

6. In

TEST OUTPUTS

screen, press

NO

. This ad-

vances to

TEST SWITCHES

.

7. Pressing

NO

in this screen will advance to the

next

function. Press

YES

in the

TEST SWITCHES

screen

to test the switches. The display will read

NOTH-

ING PRESSED

.

8. From this screen, press any of the switches on the

front of the brewer. While the switch is pressed,

the display shows the name of that switch. If the

name does not appear, or if it remains after the

switch has been released, the switch is defective.

Each switch can be tested in this manner.

9. After all switches have been tested, press and

release either of the ® buttons located on the front

switch panel. This will exit

TEST SWITCHES

and

return to the

MAIN SCREEN.

Procedures to test servers:

This function allows the operator to test the opera-

tion of the Soft Heat

®

servers. It will also show if the

server is correctly placed on the brewer stand.

1. Place brew funnels into rails on both sides of

brewer.

2. Place a Soft Heat

®

server beneath each brew

funnel.

3. Press and hold the ® pad until the display reads

SET NEW RECIPES.

Release the ® pad. Continue

pressing and releasing the ® pad until

SERVICE

TOOLS

appears.

4. Pressing

NO

will exit this function and advance to

the next function screen. Press

YES

to run tests on

various components and outputs within the brewer.

5. The display should read

TEST OUTPUTS

6. In

TEST OUTPUTS

screen, press

NO

. This ad-

vances to

TEST SWITCHES

. Press and release

NO

once more. The display should now read

TEST

SERVERS

7. Press

YES

in the

TEST SERVERS

screen to show

if a server is in place. The display should read

IN

PLACE

with arrows pointing to the left and right

8. Lift and pull both Soft Heat servers forward about

2 inches so that the two contacts on each server do

not touch the two contacts on the brewer.

9. The display should then read

SERVER REMOVED

with arrows pointing to the left and right.

10. After the servers have been tested, press and

release either of the

pads located on the front

switch panel. This will exit

TEST SERVERS

and

return to the

MAIN SCREEN.

Procedures to test coil frequency:

1. Place brew funnels into rails on both sides of

brewer.

2. Place a Soft Heat

®

server beneath each brew

funnel.

3. Press and hold the ® pad until the display reads

SET NEW RECIPES.

Release the ® pad. Continue

pressing and releasing the ® pad until

SERVICE

TOOLS

appears.

4. Pressing

NO

will exit this function and advance to

the next function screen. Press

YES

to run tests on

various components and outputs within the brewer.

5. The display should read

TEST OUTPUTS.

6. In

TEST OUTPUTS

screen, press

NO

. Continue to

press and release

NO

until the display reads

TEST

FREQUENCY.

7. Press and release

YES

. The display will show the

frequency of the sensor coil circuits. This is for

diagnostic service use when troubleshooting this

circuit.

8. After the coils have been tested, press and release

either of the

pads located on the front switch

panel. This will exit the

TEST FREQUENCY

func-

tion and return to the

MAIN SCREEN.

NOTE:

If the operator wishes to test more than one

function in the

SERVICE TOOLS

section (outputs,

switches, servers, or coil frequency), it is not

necessary to exit the program. Use the flow chart

for

SERVICE TOOLS

to navigate to a particular

function.