NOTE:

When gas valve GV is energized, R-W circuit is closed.

After a power interruption, the gas valve closes within 7 sec and

the furnace skips the blower on delay and immediately starts the

blower.

2. Cooling mode

When the thermostat "calls for cooling" R, G, and Y circuits

close. Simultaneously, the R-Y circuit starts the outdoor

condensing unit, and the R-G circuit energizes cooling fan

relay coil CFR and heating fan relay coil HFR. The

normally open contacts of heating relay HFR and cooling

relay CFR close, energizing the cooling speed of blower

motor BLWM. The EAC terminals are energized with 115v

when blower is operating on either heating or cooling

speed.

3. Continuous blower mode

When the R-G circuit is made, the blower motor operates on

cooling speed. During a "call for heat", the blower stops,

allowing the furnace heat exchangers to heat up more

quickly. When blower motor comes back on, it runs on

heating speed. The blower reverts to continuous operation

after the heating cycle blower off delay is completed.

C.

Start-up Procedures

Ensure that all connections have been properly made.

Light

the

pilot

using

the

procedures

outlined

on

the

lighting/operating instruction label attached to the furnace. How-

ever, when lighting the pilot for the first time, perform the

following additional steps:

1. After all connections have been made, purge the lines and

check for leaks.

WARNING:

Never purge a line into a combustion

chamber. Never use matches, candles, flame or other

sources of ignition to check for gas leakage. Use a

soap-and-water solution to check for gas leaks. Failure to

follow this warning could result in fire, explosion, per-

sonal injury, or death.

2. Allow 5 minutes to elapse after purging gas lines, then light

pilot in accordance with lighting/operating instructions on

the furnace.

The pilot flame should be soft blue in color and surround

3/8 in. to 1/2 in. of the thermocouple element tip. The flame

must never come in contact with any other part of the

thermocouple or its lead wire. The flame should merge with

the carryover flame. When the pilot flame requires adjust-

ment:

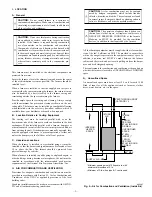

a. Locate adjustment screw on top of main gas valve next

to pilot tube. (See Fig. 12.)

b. Remove capscrew and turn adjustment screw clockwise

(in) to decrease pilot gas flow, or counterclockwise (out)

to increase pilot gas flow.

c. When proper adjustment is obtained, replace capscrew.

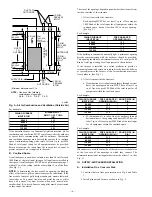

Fig. 10—Heating and Cooling Application Wiring Diagram

TABLE 5—ELECTRICAL DATA

UNIT SIZE

VOLTS—

HERTZ—

PHASE

OPERATING VOLTAGE RANGE

MAX UNIT AMPS MIN WIRE GAGE

MAX WIRE LENGTH

(FT)‡

MAX FUSE OR

HACR-TYPE

CKT BKR AMPS†

Max*

Min*

024071

115—60—1

127

104

6.7

14

44

15

036071

115—60—1

127

104

8.4

14

35

15

036091

115—60—1

127

104

9.2

14

32

15

048091

115—60—1

127

104

10.2

14

29

15

048110

115—60—1

127

104

10.0

14

30

15

060110

115—60—1

127

104

13.1

12

36

20

060135

115—60—1

127

104

14.3

12

33

20

* Permissible limits of the voltage range at which the unit will operate satisfactorily (assumes full accessory load).

† Time-delay fuse is recommended.

‡ Length shown is as measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

A78461

115-VOLT FIELD-

SUPPLIED

FUSED

DISCONNECT

AUXILIARY

J-BOX

CONTROL

BOX

24-VOLT

TERMINAL

BLOCK

TWO-WIRE

HEATING-

ONLY

FOUR

WIRE

FIELD-SUPPLIED

FUSED DISCONNECT

CONDENSING

UNIT

TWO

WIRE

FURNACE

R

G

C

W

R

G

Y

GND

GND

FIELD 24-VOLT WIRING

FIELD 115-, 208/230-, 460-VOLT WIRING

FACTORY 24-VOLT WIRING

FACTORY 115-VOLT WIRING

NOTE:

208/230- OR

460-VOLT

THREE

PHASE

208/230-

VOLT

SINGLE

PHASE

WHT

BLK

WHT

BLK

If any of the original wire,

as supplied, must be replaced, use

same type or equivalent wire.

NOTE: Connect Y-terminal as

shown for proper

operation.

W

Y

GND

THERMOSTAT

TERMINALS

—8—

→