installations, all electrical connections must be made in accordance

with Canadian Electrical Code CSA C22.1 or authorities having

jurisdiction.

B.

24-v Wiring

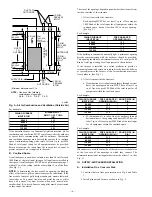

Make field 24-v connections at the 24-v terminal strip. (See Fig. 9

and 10.) Connect terminal Y as shown for proper operation in

cooling mode. Use only AWG No. 18 color-coded wire.

The 24-v circuit contains an automotive-type, 3-amp fuse located

on the main control board. Any direct shorts during installation,

service, or maintenance could cause this fuse to blow. If fuse

replacement is required, use ONLY a 3-amp fuse of identical size.

C.

Accessory

Electronic air cleaner (EAC)

Two screw terminals (EAC-1 and EAC-2) are provided for

EAC connection. The terminals are energized with 115-v,

1-amp maximum during blower motor operation.

VII.

VENTING

Refer to the enclosed Installation Instructions, GAMA Venting

Tables for Category I Furnaces and EZ VENT™ Tables for

Category I Fan-Assisted Furnaces. The horizontal portion of the

venting system shall maintain a minimum of 1/4-in. upward slope

per linear ft and it shall be rigidly supported every 5 ft or less with

hangers or straps to ensure that there will be no movement after

installation.

VIII.

START-UP, ADJUSTMENT, AND SAFETY CHECK

A.

General

The furnace must have a 115-v power supply properly connected

and grounded. Thermostat wire connections at R,W,C, and Y must

be made at the 24-v terminal block on the control board. The gas

service pressure must not exceed 0.5 psig (14-in. wc), but must be

no less than 0.16 psig (4.5-in. wc).

Before operating the furnace, check each manual reset switch for

continuity. If necessary, press the button to reset the switch.

The blower compartment door must be in place to complete the

115-v circuit to the furnace.

CAUTION:

This furnace is equipped with a fuse link in

the gas control area. The switch will open and shut off

power to the gas valve if a flame rollout or an overheating

condition occurs in the gas control area. DO NOT bypass

the switch. Correct inadequate combustion air supply

problem and reset the switches.

B.

Sequence of Operation

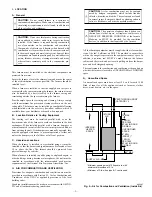

Using the schematic diagram shown in Fig. 11, follow the

sequence of operation through the different modes. (See Fig. 11.)

NOTE:

When the blower door is in place, 115v is supplied

through blower door switch ILK to heating fan relay HFR, and

transformer TRAN. Transformer TRAN energizes the safety

circuit containing auxiliary limit switch ALS, fuse link FL, and

limit switch LS to energize R.

With the furnace pilot lit, the thermocouple will energize the

thermal magnet circuit of gas valve GV, permitting gas flow to the

remaining portion of the gas valve.

1. Heating mode

a. When the wall thermostat "calls for heat," the R-W

circuit closes. This closed circuit supplies power to the

24-v safety circuit containing automatic reset limit

switch LS and fuse link FL.

b. The inducer motor relay coil IDR is energized. Inducer

motor relay contacts in the 115-v circuit close, starting

inducer motor IDM. Simultaneously, another set of

contacts in the inducer motor relay IDR closes in the

24-v circuit and locks in until the R-W circuit or safety

circuit opens.

c. As inducer motor IDM comes to speed, pressure switch

PRS actuates and supplies power through manual reset

draft safeguard switch DSS. This process energizes both

solenoid coils in gas valve GV, causes the valve to opens

which permits gas flow to the main burners where the

gas is ignited by the pilot.

d. Simultaneously, the solid-state time-delay circuit in the

blower control center is energized. Approximately 45

sec after the R-W circuit closes, heating fan relay coil

HFR is energized, closes the 115-v contacts of the

heating fan relay HFR and starts blower motor BLWM

on heating speed. EAC terminals energize with 115v

when blower operates in either heating or cooling speed.

e. When the thermostat is satisfied, the R-W circuit is

broken, de-energizing both solenoid coils of gas valve

GV and the solid-state time-delay circuit for the heating

fan relay HFR. Gas flow to the main burners immedi-

ately stops. Approximately 120 sec (or 180 sec depend-

ing on the blower off time selected) after main burners

are extinguished, heating fan relay HFR is de-energized

and blower motor BLWM stops. The blower off delay

can be permanently changed to 180 sec by cutting

resistor. (See Fig. 9.)

f. If the pilot flame is extinguished, the thermocouple no

longer energizes the thermal magnet circuit of gas valve

GV. Gas flow to the pilot and main burners stops until

the pilot is manually relit.

Fig. 9—Control Center

A91226

MAX. 1.0 AMPS

115-VAC

SEC-2

SEC-1

GROUND

SCREW

REQUIRED

FU

3-AMP

FUSE

BLOWER

OFF-DELAY

24-VAC

COMMON

CES0110074-00

W

Y

R

C

G

EAC-2

EAC-1

COM

PR-2

L2

CFR

HI

HFR

L1

PR-1

PL-1

1

2

3

4

5

6

7

8

9

1

3

IDR

24-VAC COMMON

BLOWER

OFF-TIME

ADJUSTMENT

24-VAC

THERMOSTAT

TERMINALS

COOLING

SPEED TAP

TERMINAL

HEATING

SPEED TAP

TERMINAL

115-VAC

NEUTRAL

TERMINALS

115-VAC

LINE

VOLTAGE

115-VAC

TRANSFORMER

9-PIN

CONNECTOR

ELECTRONIC

AIR-CLEANER

TERMINALS

24-VAC POWER

LO

24-VAC FUSE

3-AMP ONLY

UNCUT: 120 SEC

CUT: 180 SEC

—7—