EXAMPLE:

Heat value = 980 Btu/cu ft

Specific gravity = 0.58

Therefore; Orifice No. 42 *

Manifold pressure 3.5-in. wc

* The furnace is shipped with No. 44 orifices. Therefore, in

this example all main burner orifices must be changed and

the manifold pressure must be adjusted.

(7.) Proceed to item c. to adjust manifold pressure.

b. Check gas input rate by clocking gas meter.

(1.) Obtain average yearly heat value for local gas

supply.

NOTE:

Be sure heating value of gas used for calculation is

correct for altitude. Consult local gas utility for altitude adjustment

of gas heating value.

(2.) Turn off all other gas appliances and pilots.

(3.) Start furnace and let run for 3 minutes.

(4.) Measure time (in sec) for gas meter to complete 1

revolution.

(5.) Refer to Table 7 for cu ft of gas per hr.

(6.) Multiply gas rate (cu ft/hr) by heating value (Btu/cu

ft).

EXAMPLE:

Btu heating input = Btu/cu ft X cu ft/hr

Heating value of gas = 1070 Btu/cu ft

Time for 1 revolution of 2-cu ft dial = 72 sec

Gas rate = 100 X 1070 = 107,000 Btuh

(7.) Measured gas input should not exceed gas input on

unit rating plate.

(8.) Proceed to item c. to adjust manifold pressure.

c. Adjust gas input.

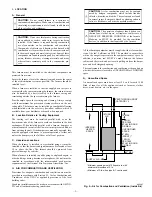

(1.) Remove regulator adjustment seal cap. (See Fig.

12.)

(2.) Turn adjusting screw counterclockwise to decrease

input. Turn screw clockwise to increase input. DO

NOT set manifold pressure less than 3.2-in. wc or

more than 3.8-in. wc for natural gas. Make any

major adjustments by changing main burner ori-

fices.

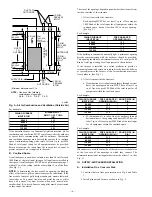

(3.) When correct input is obtained, replace regulator

seal cap. Main burner flame should be clear blue,

almost transparent. (See Fig. 13.)

d. High altitudes—In the U.S.A., gas input on rating plate

is for altitudes up to 2000 ft. Ratings for altitudes over

2000 ft must be 4 percent less for each 1000 ft above sea

level. To obtain the adjusted altitude rating, adjust the

manifold pressure, item c., and replace the main burner

orifice as needed. Refer to NFGC Appendix F, Table F-4

for proper orifice sizing at high altitudes.

e. Canadian installations only—The Canadian ratings are

approved for altitudes up to 2000 ft for natural and

propane gases. High-altitude ratings are from 2001 ft to

4500 ft above sea level. High-altitude input ratings

include a 10 percent derate as required by Canadian

standards. (See Table 8.)

2. Set temperature rise.

Do not exceed the temperature rise range specified on the

unit rating plate. Determine the air temperature rise as

follows:

a. Place duct thermometers in return and supply ducts as

near furnace as possible. Be sure thermometers do not

"see" heat exchangers so that radiant heat will not affect

thermometer readings. This is particularly important

with straight-run ducts.

b. When thermometer readings stabilize, subtract return-air

temperature from supply-air temperature to determine

temperature rise.

c. Adjust air temperature rise by adjusting blower speed.

Increase blower speed to reduce temperature rise. De-

crease blower speed to increase temperature rise.

Fig. 12—Redundant Automatic Gas Control Valve

A89171

PILOT

OFF

ON

THERMOCOUPLE

CONNECTION

PILOT

ADJUSTMENT

SCREW

MANUAL

ON/OFF

KNOB

INLET

PRESSURE

TAP

PILOT TUBE

CONNECTION

MANIFOLD

PRESSURE

TAP

REGULATOR

ADJUSTMENT

SEAL CAP

Fig. 13—Burner Flame

A84076

BURNER FLAME

PILOT FLAME

BURNER

MANIFOLD

—11—