WARNING:

This furnace must be installed in the down-

flow configuration ONLY. Improper installation, adjust-

ment, alteration, service, maintenance, or use can cause

carbon monoxide poisoning, explosion, fire, electrical

shock, or other conditions which may cause personal

injury, loss of life, or property damage. Consult a

qualified installer, service agency, local gas supplier, or

your distributor or branch for information or assistance.

The qualified installer or agency must use only factory-

authorized and listed kits or accessories when modifying

this product. Failure to follow this warning could result in

electrical shock, fire, personal injury, or death.

The design of the downflow gas-fired furnace is A.G.A./C.G.A.

certified for natural and propane gas and for installation on

noncombustible flooring. The furnace may be installed on com-

bustible flooring when installed with the accessory downflow

subbase. This furnace is for installation in alcoves, attics, base-

ments, closets, or utility rooms. The design of this furnace line is

not A.G.A./C.G.A. certified for installation in mobile homes,

recreation vehicles, or outdoors.

Before installing the furnace, refer to the current edition of the

National NFGC. Canadian installations must be installed in

accordance with NSCNGPIC and all authorities having jurisdic-

tion. For further information, the National Fuel Gas Code is

available from National Fire Protection Association Inc., Battery-

march Park, Quincy, MA 02269, American Gas Association, 1515

Wilson Boulevard, Arlington, VA 22209, or from Literature

Distribution.

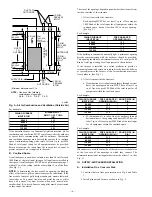

TABLE 2—DIMENSIONS (IN.)

UNIT SIZE

A

D

E

VENT CONN SHIP. WT

024071

14-3/16 12-9/16 12-11/16

4

135

036071

14-3/16 12-9/16 12-11/16

4

139

036091

17-1/2

15-7/8

16

4

146

048091

17-1/2

15-7/8

16

4

146

048110

17-1/2

15-7/8

16

4

163

060110

21

19-3/8

19-1/2

4

171

060135

24-1/2

22-7/8

23

5

182

CAUTION:

Application of this furnace should be in-

doors with special attention given to vent sizing and

material, gas input rate, air temperature rise, and unit

sizing. Improper installation or misapplication of the

furnace can require excessive servicing or cause prema-

ture component failure.

Reference should also be made to the regulations of the serving gas

supplier and the local building, heating, plumbing, or other codes

in effect in the area in which the installation is made. In the

absence of local codes, the installation must conform with the

NFGC.

This furnace is designed for a minimum continuous return-air

temperature of 60°F db or intermittent operation down to 55°F db

such as when used with a night setback thermostat. Return-air

temperature must not exceed a maximum of 85°F db.

For accessory installation details, refer to the applicable installa-

tion literature.

NOTE:

Remove all shipping brackets and materials before oper-

ating the furnace.

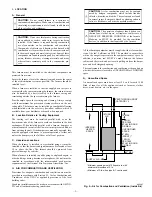

Fig. 1—Dimensional Drawing

A88324

—2—

→