TABLE 3—OPENING DIMENSIONS (IN.)

FURNACE CASING

WIDTH

A

B

Heat-Only

Heat/Cool*

14-3/16

13-1/8

19-5/8

19-7/16

17-1/2

16-7/16

19-5/8

19-7/16

21

19-7/8

19-5/8

19-7/16

24-1/2

23-7/16

19-5/8

19-7/16

* These dimensions apply when a model CB or CD Evaporator Coil casing is

to be installed.

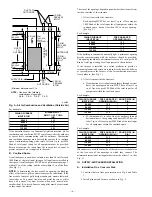

B.

Installation On a Combustible Floor

1. Cut and frame hole in floor per dimensions in Installation

Instructions packaged with downflow subbase.

2. When completed, downflow subbase, plenum, and furnace

(or coil casing when used) should be installed as shown in

Fig. 6.

WARNING:

DO NOT INSTALL THE FURNACE ON

ITS BACK OR SIDES; safety control operation will be

adversely affected. Never connect return-air ducts to the

sides or back of the furnace. Failure to follow this

warning could result in fire, personal injury, or death.

IV.

FILTER ARRANGEMENT

WARNING:

Never operate unit without a filter or with

filter access door removed. Failure to follow this warning

could result in fire, personal injury, or death.

The 2 factory-supplied filters are shipped in the blower compart-

ment. After the return-air duct has been connected to the furnace,

install the filters in a V-formation inside the return-air plenum.

(See Fig. 7.)

V.

GAS PIPING

Gas piping must be installed in accordance with national and local

codes. Refer to the current edition of the NFGC. Canadian

installations must be made in accordance with NSCNGPIC and all

authorities having jurisdiction.

The gas supply line should be a separate line directly from the

meter to the furnace, if possible. Refer to Table 4 for recom-

mended gas pipe sizing. Risers should be used to connect to the

furnace and to the meter.

TABLE 4—MAXIMUM CAPACITY OF PIPE*

NOMINAL

IRON

PIPE

SIZE

(IN.)

INTERNAL

DIAMETER

(IN.)

LENGTH OF PIPE (FT)

10

20

30

40

50

1/2

0.622

175

120

97

82

73

3/4

0.824

360

250

200

170

151

1

1.049

680

465

375

320

285

1-1/4

1.380

1400

950

770

660

580

1-1/2

1.610

2100

1460

1180

990

900

* Cubic ft of gas per hr for gas pressures of 0.5 psig (14-in. wc) or less, and a

pressure drop of 0.5-in. wc (based on a 0.60 specific gravity gas). Ref: Table

C-2 NFPA 54/ANSI Z223.1-1992.

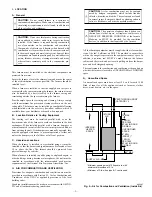

Fig. 4—Floor Opening for Concrete Slab

A73382

HOLE IN

FLOOR

A

B

Fig. 5—Furnace on a Concrete Slab (Non-Garage

Installation)

A73383

FURNACE

PLENUM

Fig. 6—Furnace, Plenum, and Subbase Installed on a

Combustible Floor

A78651

DOWNFLOW

SUBBASE

SHEET METAL

PLENUM

FURNACE

(OR COIL CASING

WHEN USED)

—5—