29

•

FEED WATER CHARACTERISTIQUES

The water physical-chemical characteristics are very important for the proper operation and the durability of the boiler or thermo-stove.

Among the consequences inconvenient caused by the low quality of the feed water, the most frequent consequence is the incrustation in the

thermal exchange surfaces.

It is also known that calcareous incrustations reduce the thermal exchange, even with a few millimetres, causing that some localised heat

spots are harmful. It is strongly recommended to do a water treatment in the following cases:

a.

The maximum water hardness must not exceed 60 mg/l.

b.

Very large installations.

c.

Consecutive fillings caused by maintenance works of the installation or produced by loss.

For the treatment of the feed water of the thermal installation it is recommended to ask for an authorised fitter.

•

FILLING THE SYSTEM

When the hydraulic connections are finished you can connect the system.

Open all the air vent valves of the radiators, thermo-stove and installation.

WARNING!! The thermo-stove is provided with an automatic air vent valve. Make sure all the air vent devices are placed in the highest

of installation because it might not be enough. Do not forget to purge the circulating pump.

Open the fill tap gradually making sure that all the air vent valves work normally. Control the installation is under pressure by using a gauge.

Pressure must be between 1.1 and 1.2 bars with an installation provided with a closed tank. Close the fill tap and purge again the air on the

boiler through the air vent valve.

It is compulsory that each installation is equipped with a back end protection valve (thermal shock valve)to permit uniform

temperatures at the start up of the boiler or thermo-stove and to avoid condensation inside the combustion chamber.

Bronpi approved Distributors can supply such a valve.

7 STARTUP

The ignition of this kind of equipments is automatic, so, please do not put on the burner any kind of material to ignition.

It is forbidden to use liquid substances such as alcohol, gasoline, petroleum or similar products. The use of this substance

leads the loss of warranty.

Before the ignition, follow the next verifications:

-

The electrical cable must be connected to the electrical network (230 Vac) with a socket equipped with earthing system.

-

The bipolar switch, placed on the rear side of the thermo-stove, must be in position I.

-

The pellet tank must be supplied.

-

The combustion chamber must be clean.

-

The burner must be clean and properly placed.

-

The combustion chamber door must be closed correctly.

During the first ignition could happen that the thermo-stove has finished the ignition cycle and there is no flame. In this case the thermo-stove

automatically starts an alarm state. This happens because the fuel feeder is empty and needs a moment to fill in. To solve this problem start

again the thermo-stove (taking into account the previous considerations) until the flame appears.

The thermo-stove, at the beginning, must be subject to different start-up cycles so that all materials and the paint can complete different

elastic expansions.

At the beginning, it is possible that you note smoke or smell which are typically produced when metals are subject to high temperatures or

when the paint is still fresh. This paint is boiled at 80º C for a few minutes when construction, but it must exceed for a time the temperature of

200 ºC before the adhesion to the metallic surfaces.

Therefore, it is important to adopt these measures during the ignition phase:

1.

Assure that there is a good air refill in the place where the equipment is installed.

2.

During the firsts ignitions, keep a low power work and the oven lit during at least 6-10 hours continuously.

3.

Repeat this operation at least 4-5 times or more, depending on the needs.

4.

During the first ignitions, you should not place any object on the equipment and, in particular, on lacquered surfaces. Lacquered

surfaces should not be touched while the equipment is heated.

8

SERVICING AND CARE

The maintenance operations guarantee a proper working of the product over

its lifetime. Not making these maintenance operations will affect the security

of the product.

8.1

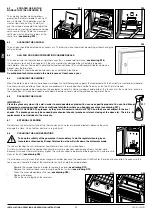

BURNER CLEANING

The burner cleaning must be made daily (

see drawing D13

).

•

Remove the burner from its place and clean the holes.

•

Use a vacuum to clean the ashes in the burner. You can buy a Bronpi vacuum-cleaner in the same Bronpi distributor where you

bought your stove.

D13

EN

INSTALLATION, OPERATING AND SERVICING INSTRUCTIONS

HYDRO SERIES

Содержание Dama Hydro

Страница 107: ...106 12 1 DAMA H FT ...

Страница 109: ...108 12 2 LETICIA H FT ...

Страница 111: ...110 12 3 REYNA H FT ...