3

101

E

N

G

IN

E ASS

E

M

B

LY AN

D CO

NTRO

LS

1

2

3

4

32

6Nm

10Nm

6Nm

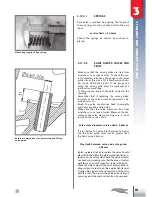

Element

Cables

Resistance values

Pick up

Red – Green

100

Ω

± 20%

Stator

Black - Black

0,46

Ω

±20%

Coupling pick up to crankcase.

Coupling chain guard to crankcase.

Mounting bushes in lower eyelets of chain guard.

3.16.1 CHECKING IGNITION SY-

STEM

Degrease the various elements and carry on with the

controls.

The main control is the one concerning the electrical

verification which can be done by using a standard

tester. The resistance values detected at the termi

-

nal heads must respect those carried in the table (at

20°C).

3.16.2 COUPLING IGNITION SY-

STEM TO CRANKCASE

Set the pick-up on the crankcase so that the two ho

-

les on its support coincide with the two outer holes

on the crankcase.

Apply the threading of the two screws

1

with me

-

dium strength threadlocker and tighten them at a

torque of 6Nm.

Lay the cable on the crankcase, apply the groo

-

ve of the cable gland

2

with gasket paste

(code

3625000000)

and insert it in the specific housing

n the crankcase, removing excess paste.

Couple the chain guard to the crankcase, insert the

two 6.2x9x9 bushes in the lower eyelets and couple

the two screws

1

after having applied them with me

-

dium strength threadlocker. Then tighten them at a

torque of 10Nm.

Attention:

pay close attention so that the cables

are well fastened to the wall of the crankcase

halves near the cable gland.

Apply the oil jet

3

so that the bottom edge enters

the hole of the cover. Insert the screw

4

previously

spread with medium strength threadlocker.

Tighten the screws at a torque of 6Nm.