3

82

E

N

G

IN

E ASS

E

M

B

LY AN

D CO

NTRO

LS

A

Should the sliding surfaces with the rotors present deep

or evident traces of corrosion, replace the deteriorated

part (in this case, the crankcase).

To measure the radial play between the internal and

external rotor and between the external rotor and the

crankcase, proceed as follows:

Insert the two rotors in their specific seat with the refe

-

rence dot facing the inside of the engine.

Using a thickness gauge, check that the play does not

exceed that allowed, equal to:

Maximum radial play: 0,20mm

Take a thickness gauge again and a rectified reference

surface and verify that the axial play does not exceed

the maximum allowed amount:

Maximum axial play: 0,1mm

Should play be greater, replace the rotors.

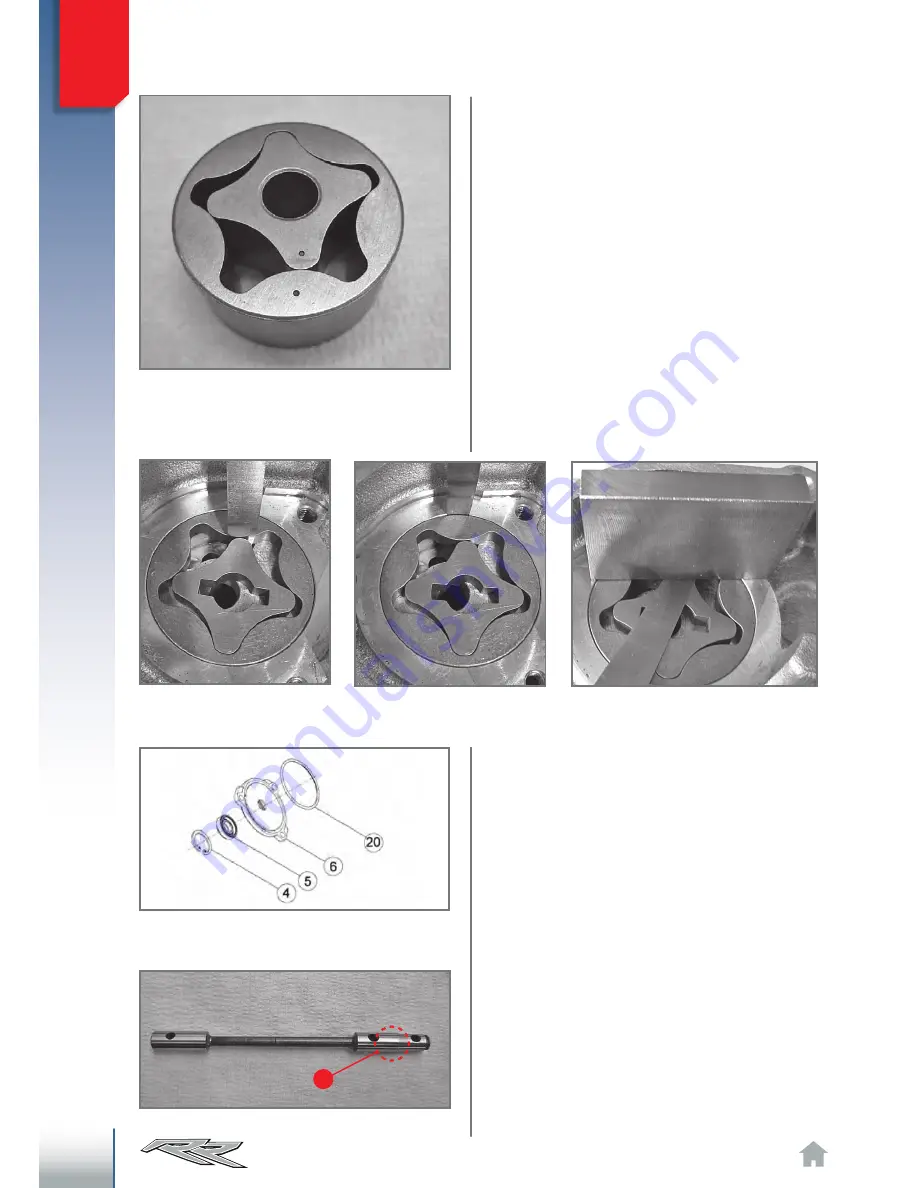

As to the high-pressure pump (located in the out

-

side right crankcase half), one must check that the

oil seal

5

is not worn (it is recommended to repla

-

ce it). In order to disassembly it, the circlip

4

must

be removed. Check the state of use of the O-ring

20

and replace it if needed.

Also check that the drive shaft is not too marked

in the zone

A

where the oil seal slides.

Low pressure pump: note the dot on the two rotors.

The dot must face the inside of the engine.

Exploded view of high-pressure pump cover. 4) Circlip

JS24; 5) Oil seal 10x22.6; 6) Oil pump cover; 20)

O-ring 45x2.

Checking oil pump control shaft.

Assessment of radial play between

and internal and external rotor.

Assessment of radial play

between external rotor and

crankcase.

Assessment of radial play between rotors

sliding surfaces.