3

80

E

N

G

IN

E ASS

E

M

B

LY AN

D CO

NTRO

LS

4

5

7

8

G

9

6

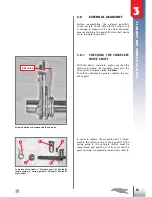

Grease the two pins

D

and

E

with graphitic grease.

Couple the idler wheel

7

to the pin

D

and apply

the circlip

8

.

Couple the torque limiter

4

to the pin

E

turning

the gearwheel with the smaller diameter towards

the crankcase half. Insert the washer

5

and the

screw 6 after having spread the threading with

medium strength threadlocker. Tighten the screw

at a torque of 10Nm.

Apply a light layer of grease in the area

G

of the

start motor and insert the motor in its housing.

Apply medium strength threadlocker on the two

screws

9

and tighten them with a torque of 10Nm.

10Nm

10Nm

Coupling electrical starter gear unit.

Insertion of start motor in crankcase half.

Note zone G to be greased.

The two fixing screws 9 of the start motor.