30

30

4. Adjusts the fence to the desired width of cut then locks it in place.

5. Checks the outfeed side of the machine for proper support and to make sure the workpiece

can safely pass all the way through the blade without interference.

6. Puts on safety glasses and a respirator.

7. Locates push sticks/blocks if needed.

8. Starts the saw.

9. Feeds the workpiece all the way through the blade while maintaining firm pressure on the

workpiece against the table and fence, and keeping hands and fingers out of the blade path

and away from the blade.

10. Stops the machine immediately after the cut is complete.

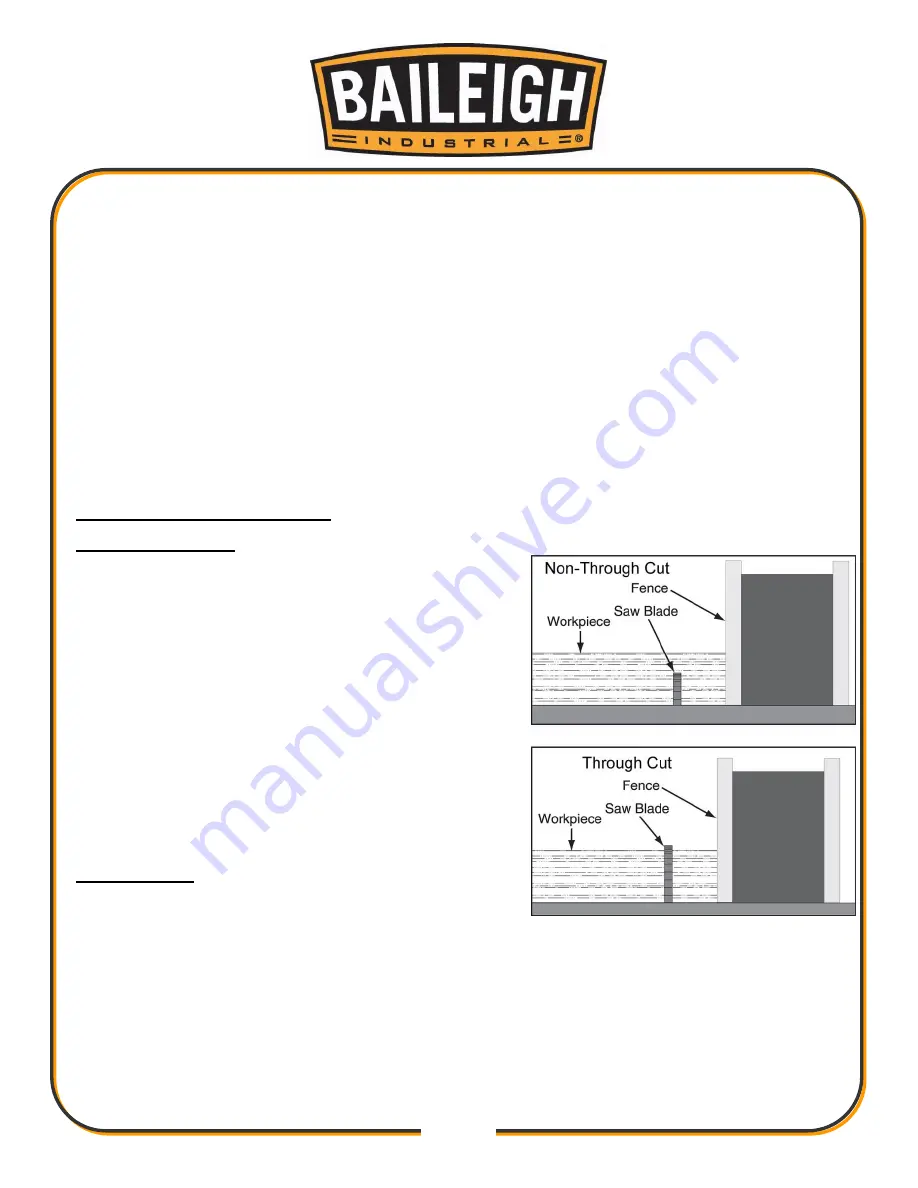

Non-Through & Through Cuts

Non-Through Cuts

A non-through cut is a sawing operation where the

blade does not protrude above the top face of the wood

stock, as shown.

Examples of non-through cuts include dadoes and

rabbets. Non-through cuts have a higher risk of injury

from kickback because the blade guard must be

removed. However, the riving knife MUST be installed

because it still provides some protection. When making

non-through cuts with a dado blade, do not attempt to

cut the full depth in one pass. Instead, take multiple

light passes to reduce the load on the blade. A dado

blade smaller than 10" will require removal of the riving

knife, because the riving knife will be higher than the

blade.

Through Cuts

A through cut is a sawing operation in which the

workpiece is completely sawn through, as shown in the

Figure below. Examples of through cuts are rip cuts, cross cuts, miter cuts, and beveled cuts.

The blade guard assembly MUST be used when performing through cuts.

Содержание TS-1040C

Страница 70: ...67 67 SAW BODY PARTS DIAGRAM...

Страница 71: ...68 68 SAW STAND PARTS DIAGRAM...

Страница 72: ...69 69 SAW TABLE PARTS DIAGRAM...

Страница 73: ...70 70 SAW TOOLS PARTS DIAGRAM...

Страница 81: ...78 78 NOTES...

Страница 82: ...79 79 NOTES...

Страница 83: ...80 80 NOTES...