EN

31

EN

30

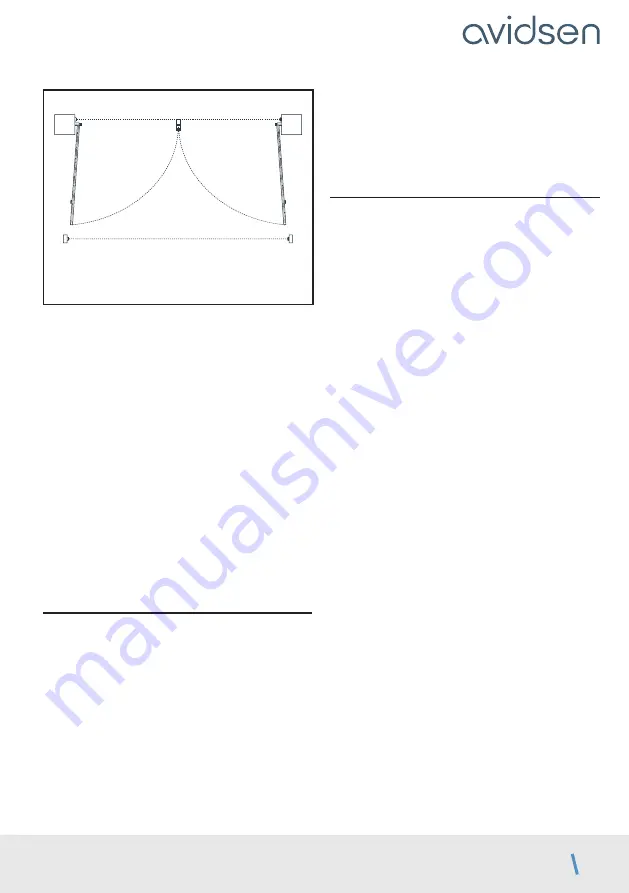

Inner side of the property

view from above

pair 2

pair 1

RX1

RX2

TX1

TX2

In that case, the system must verify that its infrared

beam is not obstructed before starting to open the

panels. But by default, photocells are only tested

during closure.

To activate or deactivate photocells at the

beginning of the opening process, follow the

procedure below

• Press “

PROG

” for 3 seconds. L0 will flash once

and L1 will switch on.

• Press “

PROG

” for 3 seconds. L0 will flash twice.

• Press “

+

” once. L2 will turn on instead of L1.

• Press

OK

.

•

If L1 is off, the photocells are inactive at the

beginning of the opening process. Press “

+

” to

activate them, then

OK

to confirm. All LEDs will

turn on and off to confirm the operation.

• If L1 is on, the photocells are active at the beginning

of the opening process. Press “–” to deactivate

them, then

OK

to confirm. All LEDs will turn on

and off to confirm the operation.

3.2.3 - TYPE OF GATE

To operate the electronic card on a single-panel

gate, this setting must be changed. By default, this

value is set to 0 (two-panel gate mode). In addition,

the motor output that remains active in side gate

mode is M1 (not to be confused with the pedestrian

passage function).

To activate or deactivate this function, follow

the procedure below

• Press “

PROG

” for 3 seconds. L0 will flash once

and L1 will switch on.

• Press “

PROG

” for 3 seconds. L0 will flash twice.

• Press “

+

” twice and L3 will turn on instead of L1.

• Press

OK

.

• If L1 is off, gate mode is activated. Press “

+

” to

activate side gate mode, then

OK

to confirm. All

LEDs will turn on and off to confirm the operation.

• If L1 is on, side gate mode is activated. Press “

–

” to

activate gate mode, then

OK

to confirm. All LEDs

will turn on and off to confirm the operation.

Self-learning is required if this setting is

changed.

3.2.4 - STOP TOLERANCE

During self-learning, the system learns the path of

each panel to determine when a panel stops if it

has reached a stop or an obstacle. In fact, during

a movement, if more than a certain percentage of

the path remains to be completed by the panel but

it comes under strain, the system considers it to

be pushing against an obstacle. If the panel comes

under strain when less than such percentage

remains to be completed, the system considers

that the panel has reached its stop. By default, this

percentage is 3%.

However, the accuracy of the system depends on

many parameters, such as temperature, motor

quality, the type of motor cables and the flexibility

and weight of the gate. Depending on these

parameters, the path measuring system may not

be accurate enough to operate with this default

tolerance. In this case, the system can trigger

obstacle detection when the panels reach their

normal stop. If this occurs (and after confirming

that the opening and closing stops are stable), the

obstacle detection tolerance must be increased.

To adjust this tolerance level, follow the

procedure below

• Press “

PROG

” for 3 seconds. L0 will flash once

and L1 will switch on.

• Press “

PROG

” for 3 seconds. L0 will flash twice.

•

Press “

+

” 3 times. L4 will turn on instead of L1.

• Press “

OK

”, and the number of LEDs lit will then

show the value set.

• Use the “

–

” and “

+

” buttons to change this value.

The higher the value, the higher the tolerance level

(“lower risk of obstacle detection at the stop”).

• Press

OK

to confirm this value. All the LEDs will

turn on and off to confirm the operation.

Self-learning is required if this setting is

changed.

D - BEGINNING OPERATION