Page - 13

6.2.c Cleaning Tri-sensor / Salt Sensor

If required, you can remove a calcium scale buildup by creating a solution of water and muriatic

acid as follows. Do not use any metallic objects to scrape the blade surfaces or you will remove

or damage the blade sensor coating.

WARNING - Failure to heed the following may result in permanent injury or death.

l

CHEMICAL HAZARD - To avoid damaging splashes always add acid to water, never water to acid.

Wear appropriate personal safety protection including safety glasses when using pool chemicals.

1. Mix the solution in a small container tall enough to cover the sensor blades. DO NOT add water to acid;

always add acid to water in container.

2. Mix one (1) part muriatic acid into four (4) parts water.

3. Immerse the salt sensor blades in the solution for up to 15 minutes. An effervescing action indicates

the calcium is being dissolved from the blades.

4. Rinse with fresh water and re-inspect. Repeat the acid treatment as necessary until all scale has been

eliminated.

6.2.d Test Tri-sensor Flow Switch

WARNING - Failure to heed the following may result in permanent injury or death.

l

Do NOT operate system with a faulty water flow switch.

The Flow Switch is a critical equipment protection device to prevent damage to the cell or

system. When water flow has stopped, power to the cell is automatically turned OFF. It is

important to verify the proper operation of the Tri-sensor’s water flow switch protection device.

The following procedure can be used to verify the proper operation of the flow switch, or to flush

debris from the bypass valve.

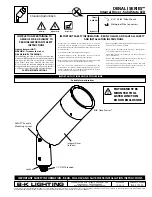

Figure 6

1. Turn off the circulation pump.

2. Slightly loosen the union nut just below the cell on the side of the

manifold that does not contain the filter screen. (A strap wrench

may be required.)

3. Completely loosen the manifold union nut that contains the filter

screen and pivot the manifold to gain access to the filter screen.

4. Remove the screen. Clean the screen if dirty.

5. If the screen was dirty, then the system may need to be purged to

remove excess debris. Leave the manifold off and run the pump for

a few seconds until clear.

6. Wrap the strainer screen securely with a small piece of plastic wrap (saran wrap, food wrap or zip lock

bag) as indicated in the diagram, place it back in the union.

7. Tighten the two unions that were loosened. Do not over tighten.

8. Turn on the pump and the Pool Pilot

®

. The plastic will stop water flow to the flow switch, which is part of

the Tri-sensor that is located in the upper portion of the manifold. All water will be forced through the

bypass valve. (This action will normally flush out any small bits of debris trapped in the bypass valve.)

9. The Pool Pilot

®

should detect a low water flow at the Tri-sensor, and activate the red CHECK SYSTEM

light. The Pool Pilot

®

will also display the message “Error purify off”; “Check flow”.

10. If the Pool Pilot

®

did not display this warning, check the Tri-sensor cable connections and inspect and

clean the Tri-sensor as outlined in the “

Inspect Tri-sensor

” and “

Cleaning Tri-sensor

” sections. If the

warning message still does not appear, then turn the Pool Pilot

®

off and contact the factory or your

local dealer for assistance.

11. Turn the pump off.

12. Loosen the unions.

13. Remove the plastic wrap and replace the strainer screen. Tighten the unions.

14. Resume normal operation.

Содержание Pool Pilot Digital Nano

Страница 2: ......

Страница 6: ......

Страница 38: ...Page 32 Figure 20 Figure 21 Figure 22 Figure 23 Figure 24...

Страница 55: ......