Section 03

ENGINE

Subsection 09

(CYLINDER AND HEAD)

03-09-22

VMR2004_132_03_09A.FM

Inspection

Piston

Inspect piston for scoring, cracking or other dam-

ages. Replace piston and piston rings if necessary.

Using a micrometer, measure piston at 8 mm

(.315 in) perpendicularly (90°) to piston pin.

1. Measuring perpendicularly (90°) to piston pin

A. 8 mm (.315 in)

The measured dimension should be as described

in the following table. If not, replace piston.

Piston/Cylinder Clearance

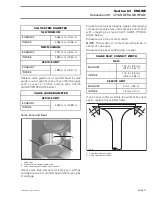

Adjust and lock a micrometer to the piston dimension.

1. Micrometer set to the piston dimension

With the micrometer set to the dimension, adjust

a cylinder bore gauge to the micrometer dimen-

sion and set the indicator to 0 (zero).

1. Use the micrometer to set the cylinder bore gauge

2. Dial bore gauge

TYPICAL

1. Indicator set to 0 (zero)

Position the dial bore gauge 20 mm (.787 in) above

cylinder base, measuring perpendicularly (90°) to

piston pin axis.

Read the measurement on the cylinder bore

gauge. The result is the exact piston/cylinder wall

clearance.

PISTON MEASUREMENT

NEW NOMINAL

OUTLANDER 330

81.950 to 81.966 mm

(3.2264 to 3.2270 in)

OUTLANDER 400

90.950 to 90.966 mm

(3.5807 to 3.5813 in)

1

R400motr96A

A

F00B08A

1

PISTON/CYLINDER CLEARANCE

NEW NOMINAL

OUTLANDER 330

0.057 to 0.087 mm

(.0022 to .0034 in)

OUTLANDER 400

0.027 to 0.057 mm

(.0011 to .0022 in)

SERVICE LIMIT

ALL MODELS

0.010 mm (.004 in)

F00B09A

1

2

F00B0AA

1

Содержание M-50 x 4

Страница 1: ...1 AUSA M 50 x 4 ROTAX ENGINE WORKSHOP MANUAL ...

Страница 2: ......

Страница 3: ......

Страница 7: ......

Страница 27: ......

Страница 31: ......

Страница 59: ......

Страница 85: ......

Страница 99: ......

Страница 136: ...Section 04 FUEL SYSTEM Subsection 03 CARBURETOR VMR2004_137_04_03A FM 04 03 1 CARBURETOR 0 V07F0ZS Harness assembly ...

Страница 147: ......

Страница 155: ......