48

ROV1-044

16. Repeat step 15 for the other piston.

Servicing Top-Side

Components

MEASURING VALVE/TAPPET

CLEARENCE

1. Rotate the engine two full revolutions.

NOTE: Rotating the engine two full revolutions will

ensure that any oil trapped in the tappet/shim is

purged to maintain an accurate clearance reading.

2. Rotate the engine until the camshaft lobe of the valve

being measured is directly away from the tappet.

3. Using an appropriate thickness gauge, measure and

record the intake and exhaust valve clearance of the

cylinder that is on the compression stroke; then rotate

the engine 360° and measure and record the valve

clearance of the other cylinder. Valve clearance must

be within specifications.

KC534A

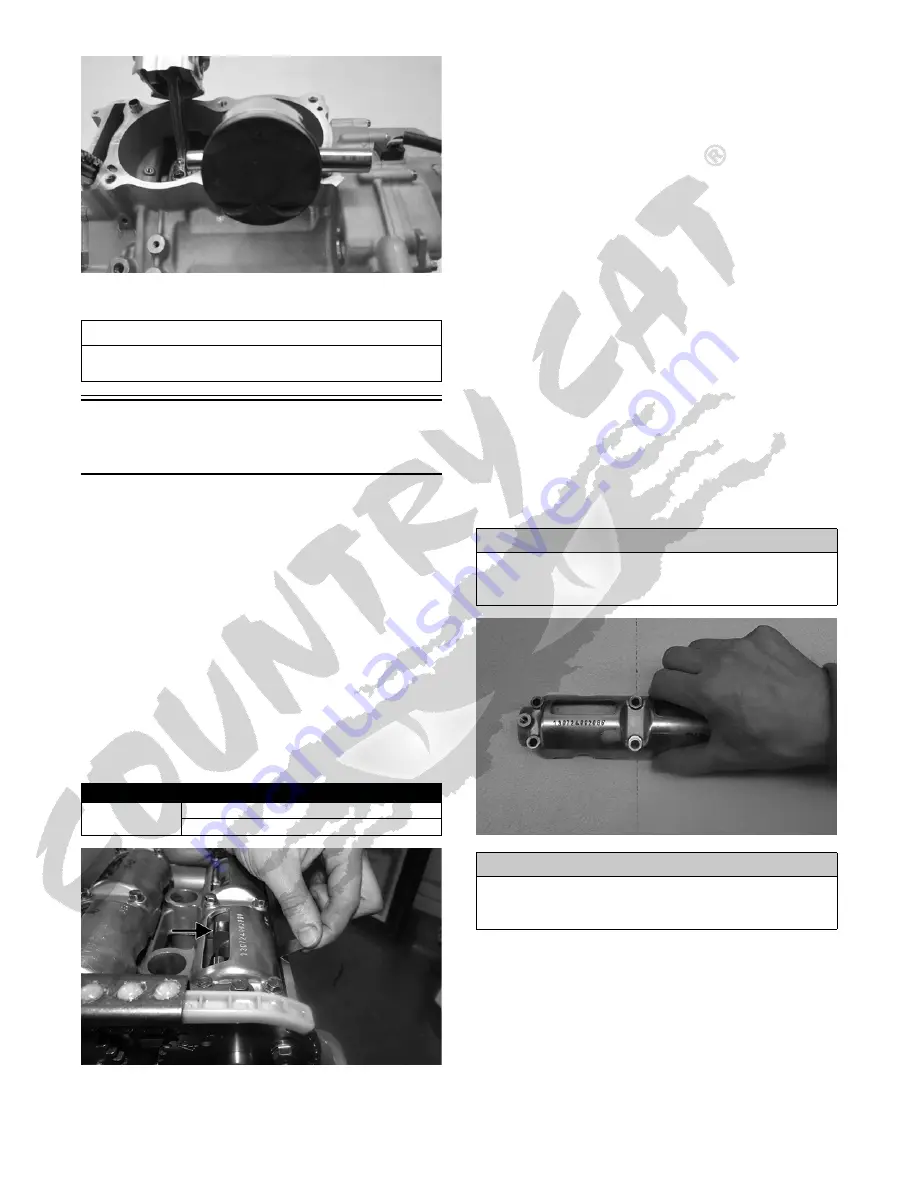

4. To select the correct replacement shim for an out-of-

specification clearance, note the three-digit number on

the surface of the existing shim; then refer to the

appropriate Tappet Shim Selection Table (Exhaust or

Intake) on the following pages and use this procedure:

A. Find the Measured Tappet Clearance (from step 3)

in the left-side vertical column of the table.

B. Find the Present Shim Size (three-digit-number) at

the top-side horizontal column of the table.

C. Match the clearance in the vertical column with the

present shim size to obtain the recommended

replacement shim.

Cleaning/Inspecting Valve Cover

NOTE: If the valve cover cannot be trued, the cylin-

der head assembly must be replaced.

1. Wash the camshaft holder in parts-cleaning solvent.

2. Place the camshaft holder on the Surface Plate cov-

ered with #400 grit wet-or-dry sandpaper. Using light

pressure, move the camshaft holder in a figure eight

motion. Inspect the sealing surface for any indication

of high spots. A high spot can be noted by a bright

metallic finish. Correct any high spots before assem-

bly by continuing to move the camshaft holder in a

figure eight motion until a uniform bright metallic fin-

ish is attained.

WT581

VALVE ASSEMBLY

When servicing valve assembly, inspect valve seats, valve

stems, valve faces, and valve stem ends for pits, burn

marks, or other signs of abnormal wear.

NOTE: Whenever a valve is out of tolerance, it must

be replaced.

AT THIS POINT

To service center crankcase components only, proceed

to Removing Left-Side Components.

Valve Clearance (Cold)

15°-25° C

(59°-77° F)

Intake: 0.16 mm (0.006 in.)

Exhaust: 0.22 mm (0.009 in.)

CAUTION

Do not remove an excessive amount of the sealing sur-

face or damage to the camshaft will result. Always check

camshaft clearance when resurfacing the valve cover.

CAUTION

Water or parts-cleaning solvent must be used in con-

junction with the wet-or-dry sandpaper or damage to

the sealing surface may result.