Commissioning

Instruction manual 91/104 V9.2

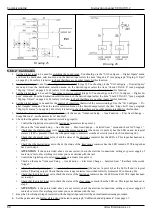

DRIVE (Connector X14)

CONNECTION

MOTOR

SIGNAL

N. PIN

N. PIN

SIGNAL

+5V (Transducer Positive Power Supply)

1

Up

0V (Transducer 0V Power supply)

2

0V

Channel “A" encoder (Track 1 incremental signal)

3

A+

Channel "A“ encoder (Track 1 incremental signal)

4

A-

0V (sock shield pair A + A)

5

Channel “B" encoder (Track 2 incremental signal)

6

B+

Channel "B“ encoder (Track 2 incremental signal)

7

B-

0V (sock shield pair B + B)

8

PTC probe in the motor (signal)

13

──────────

“CLOCK" signal encoder (serial interface)

10

CLOCK

“CLOCK“signal encoder (serial interface)

12

CLOCK

“DATA" signal encoder (serial interface)

15

DATE

“DATA“ signal encoder (serial interface)

23

DATE

PTC probe in the motor (0V)

25

──────────

0V (cable shield) – Connector case

View Flying connector from the soldering side (Connector type “D " 25 pole female).

5.5.4.1 Settings

Follow these points for proper commissioning of the transducer card:

1. Check that the X4 connector has no connection.

2. Plug the transducer connector onto X14.

3. Provide service power to the drive and perform all standard settings (paragraph "Calibration and adjustments“ on page 57

and paragraph "Setting motor parameters“ on page 57).

4. Navigate the drive menu to the parameter “Quick setup → Motor Parameters → Feedback Type". Use the keys to change

setting and select “EnDat ". If you cannot select this transducer, see the next point to check if the card is working properly.

5. Check if the card is compatible and if it has been recognised by moving to the menu “Diagnostic → Transduc. Board →

Transduc. Board for...." and verify that the word "EnDat" is present. If this does not occur, please contact the ALTER Tech-

nical Office for some verifications.

6. Check the amplitude of incremental signals connected on the X14 connector to pins 3, 4, 6, 7 and the connection of the

transducer’s electrical wires by moving to the “Diagnostic → Transduc Board → SinCos signal A and B" and verify that

there is "OK", otherwise perform these verifications:

1. Written “LOW”: check that you've connected the cable from both sides. Check the cable and welding of wires on the

X14 connector at pins 3, 4, 6, 7.

2. Written “HIGH”: check the cable and welding of wires on the X14 connector at pins 3, 4, 6, 7 that are not short-circuited

with other signals.

7. Check the correctness of the serial data connected on the X14 connector to pins 9, 10, 11, 12 and the connection of the trans-

ducer’s electrical wires by moving to the “Diagnostic → Transduc Board → Serial comm status" and verify that there is

"OK", otherwise carry out these checks:

◦

Written “FAULT ": check that you've connected the cable from both sides. Check the wiring and soldering of wires on

the X14 connector at pins 9, 10, 11, 12. Check the connection of the shield to ground on both sides of the cable. The

cable shall be of the braided pair type and the pairs shall be used as indicated in the connection table of the X14 con -

nector. The length of the cable may not exceed 150 meters.

8. Check for alarms inside the encoder by moving to the “Diagnostic → Transduc Board → Internal alarm status" and verify

that there is "OK", otherwise carry out these checks:

◦

Written “FAULT ": the encoder has internal problems. Replace it with a working one.

9. Check if the encoder is compatible with the card by moving to the “Diagnostic → Transduc Board → Compatible encoder"

and verify that it is written "YES", otherwise carry out these checks:

◦

Written ‘NO’: the encoder isn't compatible. Verify that it has the characteristics indicated at the beginning of the para -

graph.

10. If all previous verifications are positive, autotune of motor parameters can be performed as explained in paragraph "Autotune

for the calculation of optional parameters“ on page 58.

11. At the end of the autotune procedure, the parameters must be stored in order to complete the commissioning of the transducer

card.

64

Alter Elettronica s.r.l.