53277

45

Section 6 Gas Burner Conversion Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

51. NO. 459P3 NATURAL GAS CONVERSION

KIT FOR “EG” MODELS/SERIES DRYERS

This kit consists of:

NOTE: Kit will convert one gas valve; 2 kits are

needed for converting upper and lower units.

Gas Input – 25,000 BTU/HR

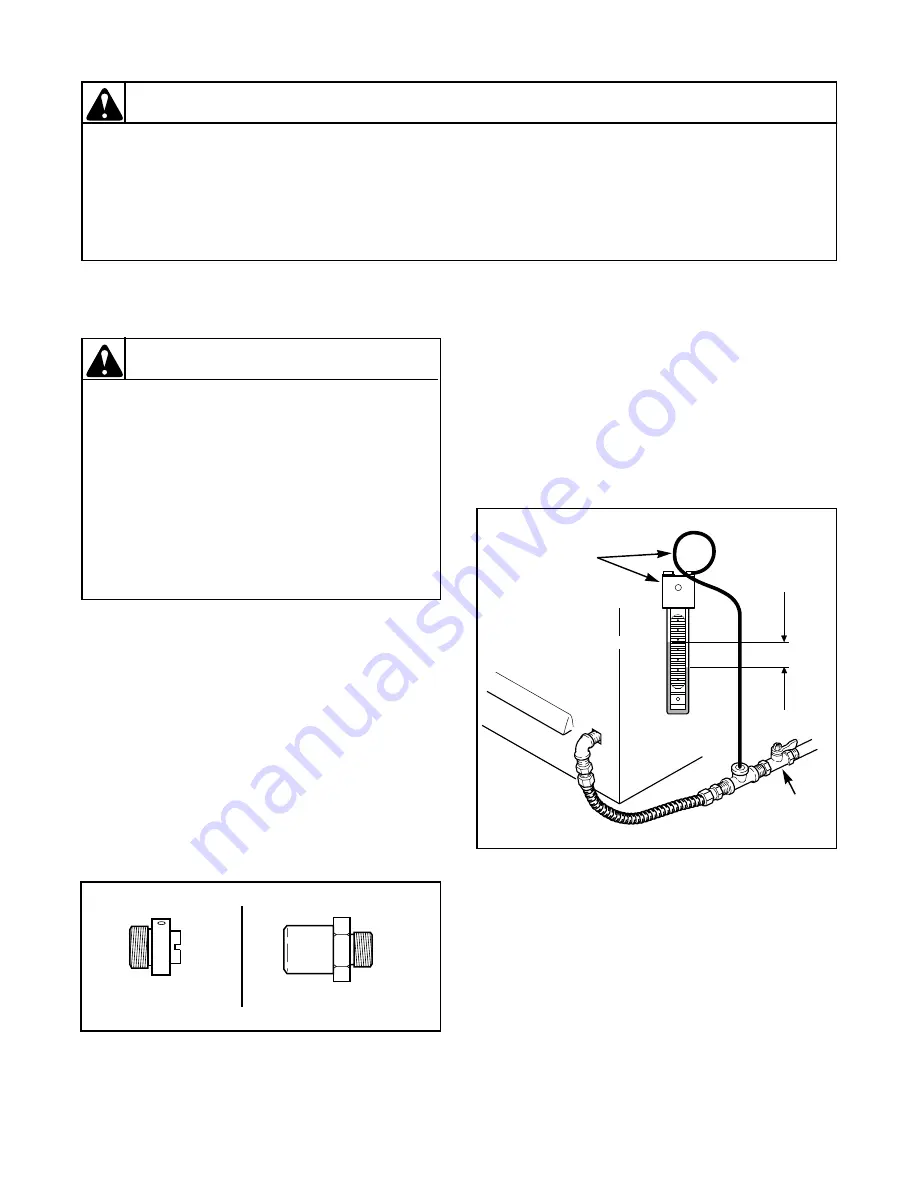

NOTE: When converting the dryer gas valve to

Natural Gas, be sure the incoming gas supply line is

equipped with a pressure regulator (located ahead

of the dryer) that will maintain the gas supply to the

dryer at 6.5 ± 1.5 inches (16.5 ± 3.81 cm) water

column pressure, and a vent to the outdoors must be

provided. Remove pressure tap pipe plug and check

gas pressure by connecting a “U” tube manometer

(or similar pressure gauge) to the pressure tap.

Refer to Figure 44.

1 - 58768

Vent Screw

1 - 60417

Burner Orifice Spud (Metal

stamped #40

1 - 60512

Conversion Plate

1 - 60516

“Valve Converted to Natural Gas”

Sticker

2 - 60519

Natural Gas Stickers

1 - 4-88-26R1 Instructions

This conversion kit is to be installed by

AUTHORIZED DEALERS or DISTRIBUTORS

on their premises and in accordance with

the manufacturer’s instructions and all

codes and requirements of the authority

having jurisdiction. Failure to follow

instructions could result in serious injury

or property damage. The qualified agency

performing this work assumes

responsibility for this conversion.

W312

WARNING

55"

DRY966S

Vent Screw

Burner Orifice Spud

Figure 44

DRY961S

MANOMETER

6.5 ± 1.5

INCHES

PRESSURE

TAP