40

–54

Software Manual EN

◼

SE-24

◼

01.06.2022

◼

V1.3

5.8.6 Settings

NOTE

The values in the “Settings” area only refer to the “Move OK” signal

which corresponds to the “move_ok” interface signal.

Detailed information about the functions are to be found in the

function description of the SE-24 operating instructions, chapter

“Function description”.

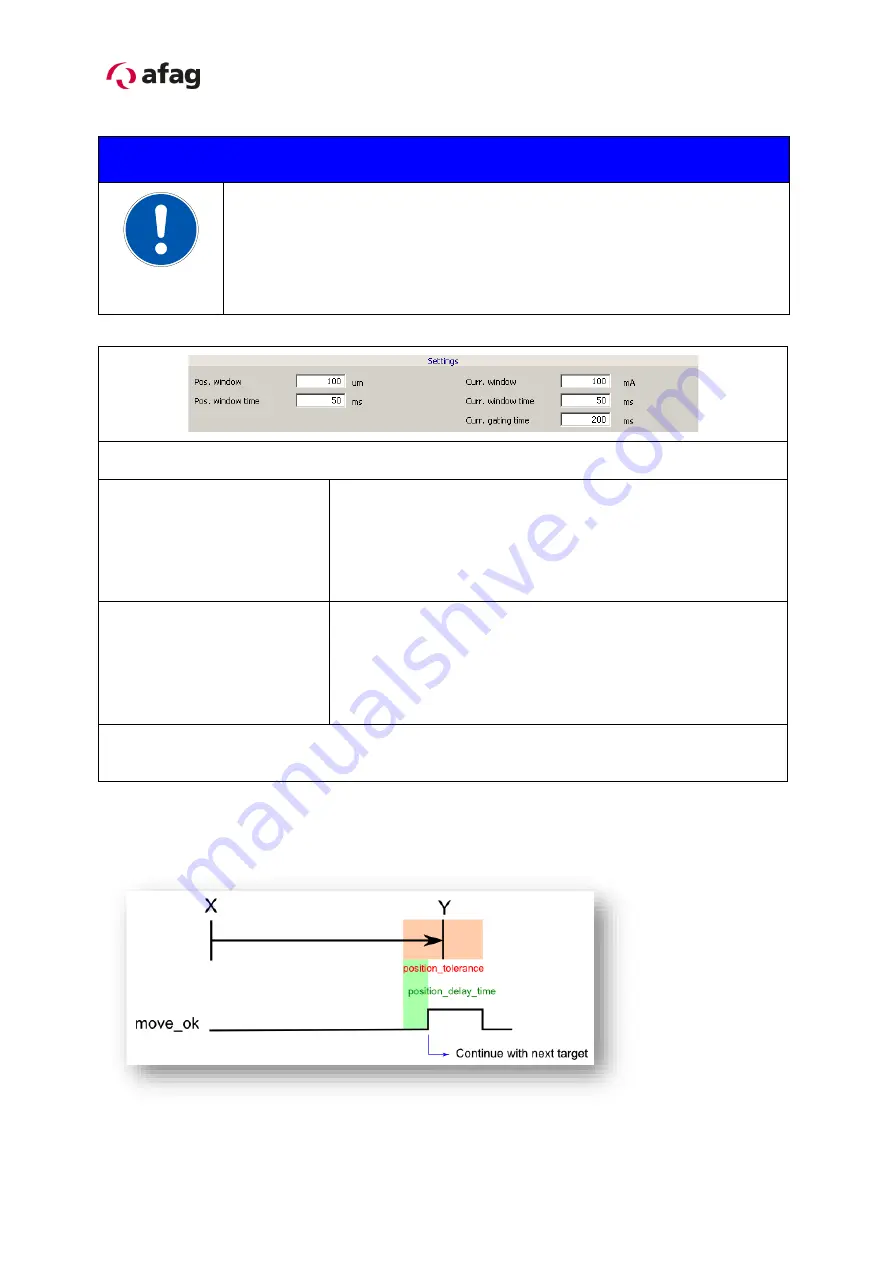

Settings for the “Move OK” signal in positioning mode.

Pos. window

This value corresponds to the tolerance for the positioning

window and is placed as a sym/- value around the

target position.

Comment: Double the value corresponds to the

“position_tolerance” value in Figure 3: Positioning mode.

Pos. window time

This value sets the delay time from the moment when the

actual position value is in the positioning window until the

“Move OK” signal is triggered.

Comment:

This

value

corresponds

to

the

“position_delay_time” in Figure 3: Positioning mode.

Comment:

The “Movement OK” signal is triggered when the delay time for the position in

the positioning window has passed.

X = position_value (actual position)

Y = target_position (target position)

Current = maximum current (from parameterization)

Figure 3: Positioning mode