I

GB

The value set can be checked on the gauge (for versions equipped with this,

fig. 11

) or the numbered notches on the knob (

fig.

12

) the values of which correspond to the related pressures.

When you have finished working, stop the machine, pull out the plug and empty the reservoir.

MAINTENANCE

The service life of the machine depends on maintenance quality.

PRIOR TO ANY OPERATION SET THE PRESSURE SWITCH TO THE OFF POSITION, PULL OUT THE

PLUG AND COMPLETELY DRAIN THE RESERVOIR.

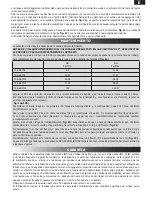

After the first hour of work, check that all screws (in particular those of the head of the unit) are tightly drawn

up, in order to restore the correct tightening torque following thermal dilatation (

fig. 13

).

Nm

Min. torque

Nm

Max. torque

Bolt M6

9.3

11.36

Bolt M8

22.45

27.43

Bolt M10

45.28

55.34

Bolt M12

77.10

94.23

Bolt M14

123

150.37

Clean the suction filter according to the type of environment and in any case at least every 100 hours. If

necessary, replace the filter (a clogged filter impairs efficiency while an inefficient filter causes harsher wear

on the compressor).

(figures 14a-14b)

.

Change the oil after the first 100 hours of operation and subsequently every 300 hours. Check the oil level

periodically.

Use APICC Sae 40 mineral oil. (For cold climates, Sae 20 is recommended). Never mix different grade oils. If

the oil changes color (whitish = presence of water; dark = overheated), it is good practice to replace the oil

immediately.

After topping up, tighten the plug (

fig. 15

) making sure that there are no leaks during use. Once a week,

check the oil level to assure lubrication in time.

(

fig. 7a

).

Periodically (or after completing work if for more than an hour), drain the condensate that forms inside the

reservoir due to the humidity in the air (

fig. 16

) in order to protect the reservoir from rust and so as not to

restrict its capacity.

Periodically, check the tension of the belts which must have a flexion (f) of around 1 cm (

fig. 17

).

Spent oil and condensate

MUST BE DISPOSED OF

in compliance with protection of the environment and

current legislation.

WARRANTY

The warranty does not cover all electrical parts and all parts that, due to their specific use, are liable to

wear. The warranty envisages the manufacturer’s obligation to repair or replace, at its discretion, parts

acknowledged as faulty by its own technicians provided that such faults refer to the construction of the

products and/or the quality of the materials (i.e. they are to be ascribed to the manufacturer) and are not

caused by normal wear, negligence, incorrect or improper use of the product by the user not complying

with the instructions, tampering, repairs or disassembly even only partial by persons not authorized by the

manufacturer, excessive use of the machine or unsuitable applications, fortuitous events or circumstances of

incorrect installation or mis-use.

All compressors with up to 100-liter receivers must be sent to the Service Center carriage free and will be

returned carriage forward.

Ask your supplier for the location of your nearest Center.

The manufacturer reserves the right to make any modifications it considers necessary without prior notice.

Содержание 556182 - 62

Страница 2: ...3b 2a 1 2b 3a 6a 4 5 ...

Страница 3: ...7a 7b 8 6b 9b 9a 11 10 ...

Страница 4: ...12 15 13 14a 14b 17 16 18a ...

Страница 5: ...20b 21 19 18b 20c 20a ...