Planning the electrical installation 55

Implementing thermal overload and short-circuit

protection

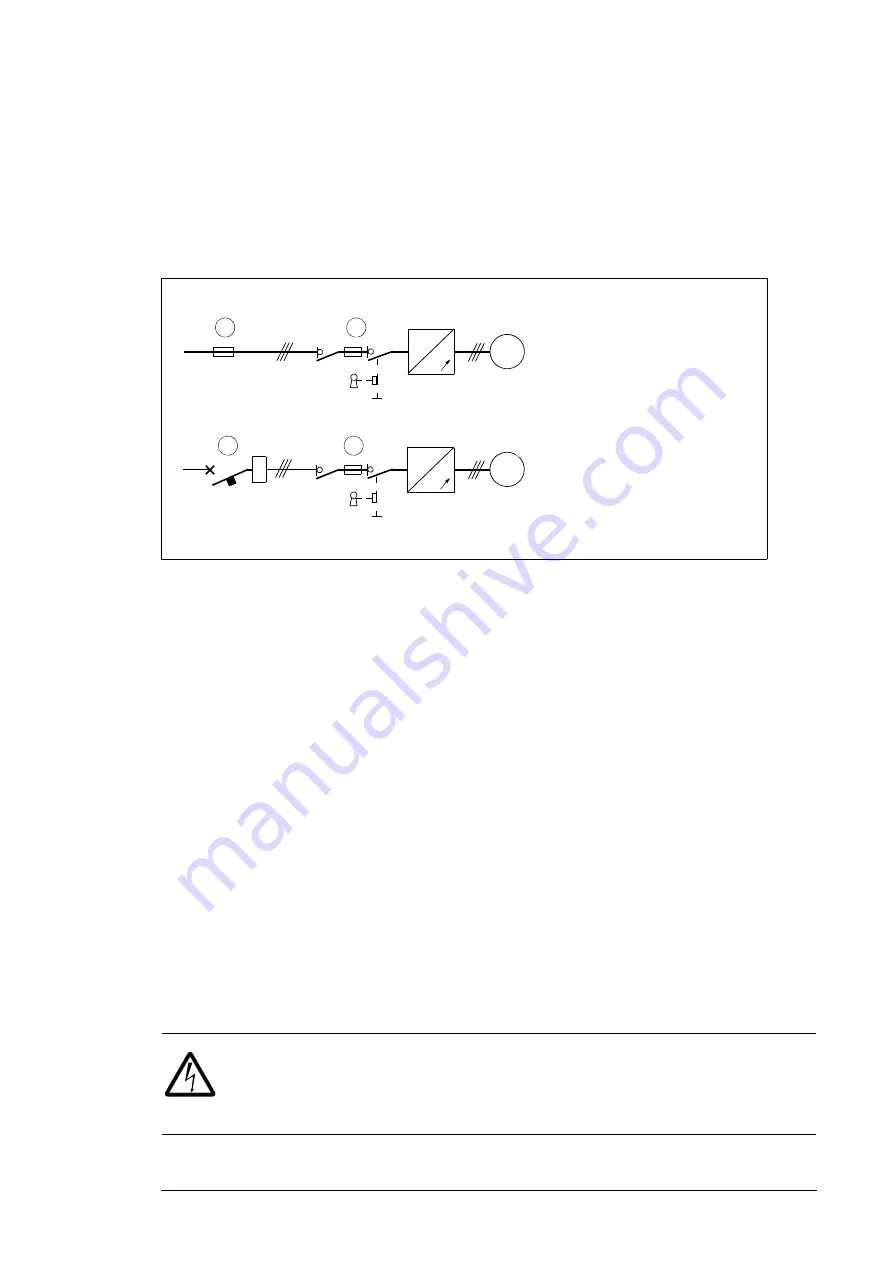

Protecting the drive and input power cable in short-circuits

Protect the drive with fuses (1) and the input cable with fuses (2) or a circuit breaker (3) as

shown below:

Size the fuses or circuit breaker at the distribution board according to local regulations for

the input cable protection. Select the fuses for the drive according to the instructions given

in chapter

The fuses for the drive protection will restrict drive damage and

prevent damage to adjoining equipment in case of a short-circuit inside the drive.

Note 1

: If the fuses for the drive protection are placed at the distribution board and the

input cable is dimensioned according to the nominal input current of the drive given in the

rating table on page

, the fuses will protect also the input cable in short-circuit

situations, restrict drive damage and prevent damage to adjoining equipment in case of a

short-circuit inside the drive. No separate fuses for the input cable protection are needed.

Note 2:

Circuit breakers must not be used without fuses.

Protecting the motor and motor cable in short-circuits

The drive protects the motor cable and motor in a short-circuit situation when the motor

cable is dimensioned according to the nominal current of the drive. No additional

protection devices are needed.

Protecting the drive and the input power and motor cables against

thermal overload

The drive protects itself and the input and motor cables against thermal overload when the

cables are dimensioned according to the nominal current of the drive. No additional

thermal protection devices are needed.

WARNING!

If the drive is connected to multiple motors, use a separate circuit

breaker or fuses for protecting each motor cable and motor against overload. The

drive overload protection is tuned for the total motor load. It may not trip due to an

overload in one motor circuit only.

~

~

M

3~

M

3~

I

>

~

~

1

2

3

1

ACQ810-04

ACQ810-04

Содержание ACQ810-04

Страница 1: ...ABB industry specific drives Hardware manual ACQ810 04 drive modules 200 to 500 kW 300 to 700 hp ...

Страница 4: ......

Страница 10: ...10 ...

Страница 22: ...22 Introduction to the manual ...

Страница 42: ...42 Planning the cabinet installation ...

Страница 75: ...Installation 75 Assembly drawing frame G1 ...

Страница 76: ...76 Installation Assembly drawing frame G2 ...

Страница 83: ...Installation 83 3 6a 6b 5 4 8 4 8 6a 6b 7a 7b 7b ...

Страница 84: ...84 Installation Assembly drawing of installing the drive module to the cabinet frame G1 ...

Страница 85: ...Installation 85 Assembly drawing of installing the drive module to the cabinet frame G2 ...

Страница 89: ...Installation 89 3AUA0000038989 TXD transmitter RXD receiver JRIB V2 V1 V7 V6 1 2 APOW 2 JINT 3 JRIB 1 4 4 JGDR ...

Страница 100: ...100 Installation ...

Страница 104: ...104 Installation checklist ...

Страница 106: ...106 Start up ...

Страница 108: ...108 Fault tracing ...

Страница 128: ...128 Technical data ...

Страница 130: ...130 Dimension drawings Frame G1 Drive module dimensions ...

Страница 131: ...Dimension drawings 131 Frame G1 Drive module dimensions with optional cabling panels H381 ...

Страница 132: ...132 Dimension drawings ...

Страница 133: ...Dimension drawings 133 Frame G1 Cabling panels H381 installed into a Rittal TS 8 cabinet ...

Страница 134: ...134 Dimension drawings Frame G2 Drive module dimensions ...

Страница 135: ...Dimension drawings 135 Frame G2 Drive module dimensions with optional cabling panels H381 ...

Страница 136: ...136 Dimension drawings ...

Страница 137: ...Dimension drawings 137 Frame G2 Cabling panels H381 installed into a Rittal TS 8 cabinet ...

Страница 138: ...138 Dimension drawings Bottom plate ...

Страница 142: ...142 du dt filters ...

Страница 144: ...3AUA0000120538 Rev A EN 2012 06 27 Contact us www abb com drives www abb com drivespartners ...