28

3.Worn rods, wrist pin or

main bearings

3.Check and replace worn parts

Knocking Noise

1.Compressor valves loose

or broken

1.Check and replace worn or broken valves

2.Inspect check valve, it

may knock at low pressures

2.Remove and clean check valve

3.Possible defect in safety

valve

3.Operate safety valve manually by pulling on ring.

If valve still leaks, it should be replaced

Excessive noise

1.Loose fittings

1.Reduce air pressure, then check all fittings with a

soap solution for air leaks and tighten as needed

Do not overtighten

2.Unit not on level surface 2.Reposition unit on a level surface

Moisture in discharge air

Too much moisture in air Install inline air filter/dryer, and/or relocate to less

humid environment

Excessive tank pressure - safety valve pops off

1.Safety valve needs

service

1.Pull on test ring of safety valve. If it still pops,

replace

2.Pressure switch does not

shut off motor when

compressor reaches "cut-o

ut" pressure

2.Set On/Off power Switch to the "

OFF

" position, if

the outfit does not shut off contact a Trained

Service Technician

3.Pressure switch "cut-out"

too high

3.Contact a Trained Service Technician

Air leaks from pump or fittings

Loose fittings

Reduce air pressure, then check all fittings with a

soap water solution for air leaks and tighten as

needed.

Do not overtighten

.

Air leaks in air tank or at air tank welds

Defective or rusted tank 1. Air tank must be replaced. Do not repair the

leak.

Risk bursting. Do not drill into, weld or

otherwise modify air tank or it will weaken. The

tank can rupture or explode.

2.Have tank replaced by a qualified technician.

Drain moisture from tank daily to prevent future

corrosion.

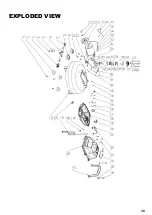

Содержание A12101

Страница 30: ...30 EXPLODED VIEW...