19

The larger the tire, the more time to

fill is needed.

NOTE:

This product is designed for

inflation, stapling, brad nailing and

air brushing.

11.

Use the air tool as needed.

12.

After the job is complete, turn the

compressor Power Switch

“OFF”

.

Note:

Turn the Power Switch off

before unplugging the compressor.

13.

Unplug the Air Compressor.

14.

Close the in-line Shutoff Valve.

15.

Bleed air by pulling ring on safety

valve, to bleed from the tool then

disconnect the tool.

16.

Turn the Drain Valve, at the bottom

of the tank, two turns to release any

built-up moisture and the internal

tank pressure.Close the valve after

moisture has drained out. Do not

remove the Drain Valve.

17.

Clean, then store the Air

Compressor indoors.

Emergency Depressurization

If it is necessary to quickly

depressurize the compressor, turn the

Power Switch

OFF

. Then, pull on the

ring on the Safety Valve to quickly

release stored air pressure.

Motor Overload Protector

(Automatic Shut Off System not

shown):

The motor has a thermal

overload protector. If the motor

overheats for any reason, the overload

protector will shut off the motor. The

motor must be allowed to cool down

before restarting. If the compressor

automatically shuts off before reaching

its normal cutoff pressure.

1.

To restart:

a)

Shut off all tools.

b)

Allow the motor to cool (about 10

minutes).

c)

If the unit does not start up again

on its own,press the Reset Button to

start the compressor

d)

Resume operation.

2.

Possible causes

of repeated

automatic shut off of the compressor

are:

a)

Using an

extension cord

that is

too

long or narrow.

b)

An

air leak

or open hose causing the

compressor to cycle too often and

build up heat.

3.

Correct any issues

before further

use to avoid damage to the

compressor.

MAINTENANCE

PROCEDURES NOT SPECIFICALLY

EXPLAINED IN THIS MANUAL MUST BE

PERFORMED ONLY BY A QUALIFIED

TECHNICIAN

.

Before doing any maintenance or

adjustments to your air compressor, the

following safety precautions should be

taken:

WARNING:

TO

PREVENT

SERIOUS

INJURY

FROM

ACCIDENTAL

OPERATION:

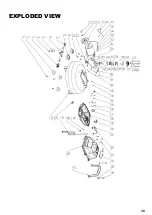

Содержание A12101

Страница 30: ...30 EXPLODED VIEW...