18

b)

Press reset button.

c)

Turn the Power Switch

ON

position.

7.

Allow the Air Compressor to build

up pressure until it cycles off.

Motor will stop when tank pressure

reaches "cut-out" pressure.

Electric motor should now start and fill

air receiver(s) with compressed air

until cut-out pressure is reached.

Compressor should stop and remain

stopped until air receiver pressure

reaches the cut-in pressure. The unit

will continue to cycle in this automatic

operation until the pressure switch is

turned to the "

OFF

" position.

NOTE:

At the beginning of the day’s

first use of the Air Compressor, check

for air leaks by applying soapy water to

connections while the Air Compressor

is pumping and after pressure cut-out.

Look for air bubbles. If air bubbles are

present at connections, tighten

connections. Do not use the Air

Compressor unless all connections are

air tight, the extra air leaking out will

cause the compressor to operate too

often, increasing wear on the

compressor.

NOTE:

As long as the Power Switch

is

ON

, the operation of the Air

Compressor is automatic, controlled

by an internal pressure switch. The

Compressor will turn on

automatically when the air pressure

drops to 85 PSI, and will turn off

automatically when the air pressure

reaches 100 PSI.

WARNING:

TO PREVENT

SERIOUS INJURY AND

DEATH FROM EXPLOSION:

Do not adjust the internal pressure

switch.

Any change to the automatic

pressure levels may cause excess

pressure to accumulate, causing a

hazardous situation.

8.

Turn regulator knob clockwise to

increase pressure and stop when

desired pressure is reached.

WARNING:

Risk of unsafe

operation. If any unusual noise or

vibration is noticed, stop the

compressor immediately and have it

checked by a trained service

technician.

AFTER

the compressor builds up

enough pressure and shuts off, adjust

the Air Compressor's Regulator Knob

so that the air output is enough to

properly power the tool, but the

output will not exceed the tool's

maximum air pressure at any time.

Turn the knob clockwise to increase

the pressure and counter-clockwise to

decrease pressure. Adjust the pressure

gradually, while checking the air

output gauge to set the pressure.

The compressor is ready for use.

9.

Make sure the air tool’s throttle or

switch is in the off position. Connect

the air tool to the air hose.

10.

Open the in-line Shutoff Valve.

NOTE:

Allow adequate time when filling tires.

Содержание A12101

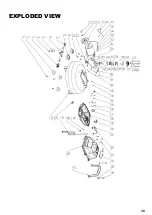

Страница 30: ...30 EXPLODED VIEW...