25

7.Extension Cord wire size

is too small or cord is too

long to properly power

compressor.

7.Use larger diameter or shorter extension cord or

eliminate extension cord. See RECOMMENDED

WIRE GAUGE FOR EXTENSION CORDS in “Safety

rules” section.

8.Compressor needs

8.Have unit inspected by a qualified technician

Motor stalls

1.Faulty unloader / check

valve

1.Replace unloader check valve

2.Valves incorrectly

2.Install valves correctly

Compressor Stops and Starts Excessively

1.Leaks in air system

1.Replace worn components as necessary

2.Pressure switch

differential adjusted too

close

2.Make necessary adjustments

3.Defective compressor

valves

3.Replace valves

4.Automatic overload

switch tripped

4. Wait 20 minutes, if the unit does not start up

again on its own. See “Motor Overload Protector”

in “OPERATION” section.contact a trained service

technician.

5.Loose fittings

5.Reduce air pressure, then check all fittings with a

soap solution for air leaks and tighten as needed.

Do not overtighten.

6.Compressor not large

enough for job

6.Check if accessory CFM is met by Compressor.

If Compressor doesn’t reach accessory CFM, you

need a larger Compressor

Compressor builds pressure too slowly

1

.

Incorrect power supply 1.Check that circuit matches compressor

requirements

2

.

Working environment

too cold

2.Move compressor to a warmer location

3

.

Safety valve leaking

3.Operate safety valve manually by pulling on ring.

If valve still leaks, it should be replaced with

identical valve with same rating.

DO NOT SEAL OR

TAMPER WITH SAFETY VALVE.

4

.

Loose fittings

4.Reduce air pressure, then check all fittings with

a soap solution for air leaks and tighten as needed.

Do not overtighten.

Содержание A12101

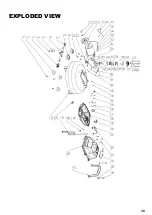

Страница 30: ...30 EXPLODED VIEW...