5 Adjustments

5.4.2 Advanced Autotuning by Reference Procedure

5-28

(2) Failure in Operation

This section describes the causes and corrective actions in case the operation has not been successfully com-

pleted.

If “NO-OP” is shown

If “Error” is shown

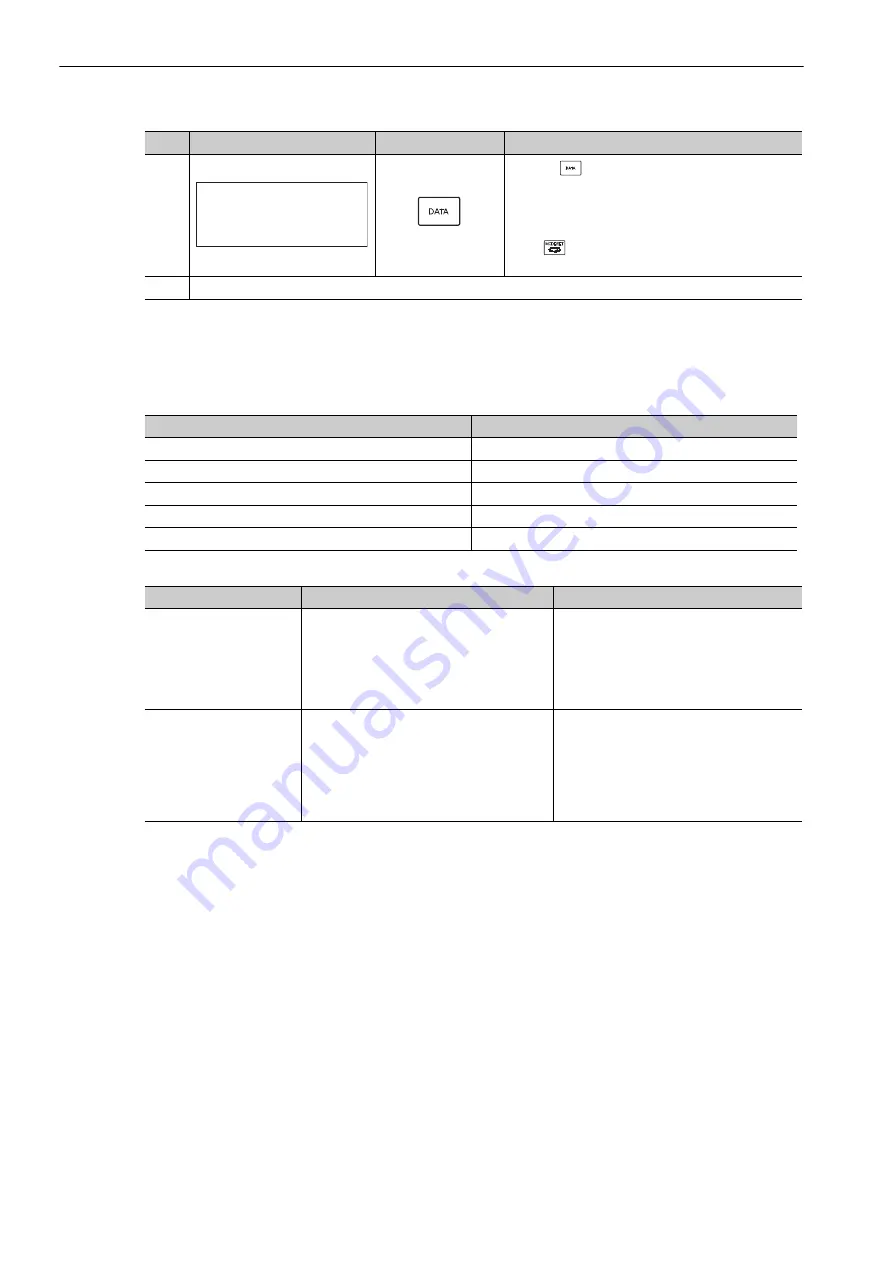

8

Press the

Key. The adjusted values will be writ-

ten to the SERVOPACK, “DONE” will blink for

approx. 2 seconds, and then “RUN” will be dis-

played.

Note: Not to save the values set in step 6, press the

Key. The display will return to the display

in step 1.

9

To enable the change in the setting, turn OFF the power and ON again.

Step

Display after Operation

Keys

Operation

㧾㨁㧺ޓޓޓޓ㧭㨐㨢㨍㨚㨏㨑㨐ޓ㧭㨀

㧼㨚㧝㧜㧟㧩㧜㧜㧟㧜㧜

㧼㨚㧝㧜㧜㧩㧜㧝㧜㧜㧚㧜

㧼㨚㧝㧜㧝㧩㧜㧜㧜㧢㧚㧟㧢

㧼㨚㧝㧠㧝㧩㧜㧝㧡㧜㧚㧜

Probable Cause

Corrective Actions

The main circuit power supply was OFF.

Turn ON the main circuit power supply.

An alarm or warning occurred.

Remove the cause of the alarm or the warning.

Overtraveling occurred.

Remove the cause of the overtravel.

Gain setting 2 was selected by gain switching.

Turn OFF the automatic gain switching.

The HWBB function operated.

Cancel the HWBB function.

Error

Probable Cause

Corrective Actions

The gain adjustment

was not successfully

completed.

Machine vibration is occurring or the posi-

tioning completed signal (/COIN) is repeat-

edly turning ON and OFF.

• Increase the set value for Pn522.

• Change the mode from 2 to 3.

• If machine vibration occurs, suppress the

vibration with the anti-resonance control

adjustment function and the vibration sup-

pression function.

The positioning

completed signal

(/COIN) did not turn ON

within approximately 10

seconds after

positioning adjustment

was completed.

The positioning completed width is too nar-

row or the proportional control (P control) is

being used.

• Increase the set value for Pn522.

• If P control is used, turn OFF the /P-CON

signal.