8.2 Coupling to the Machine

8.2.2 Using a Belt

8-6

4.

Align the shaft of the Servomotor with the shaft of the machine, and then connect the

shafts with the coupling.

8.2.2

Using a Belt

1.

Wipe off all of the anticorrosive coating from the motor shaft.

2.

If you are using a Servomotor with a Key, attach the key enclosed with the Servomotor

or the specified size of key to the shaft.

3.

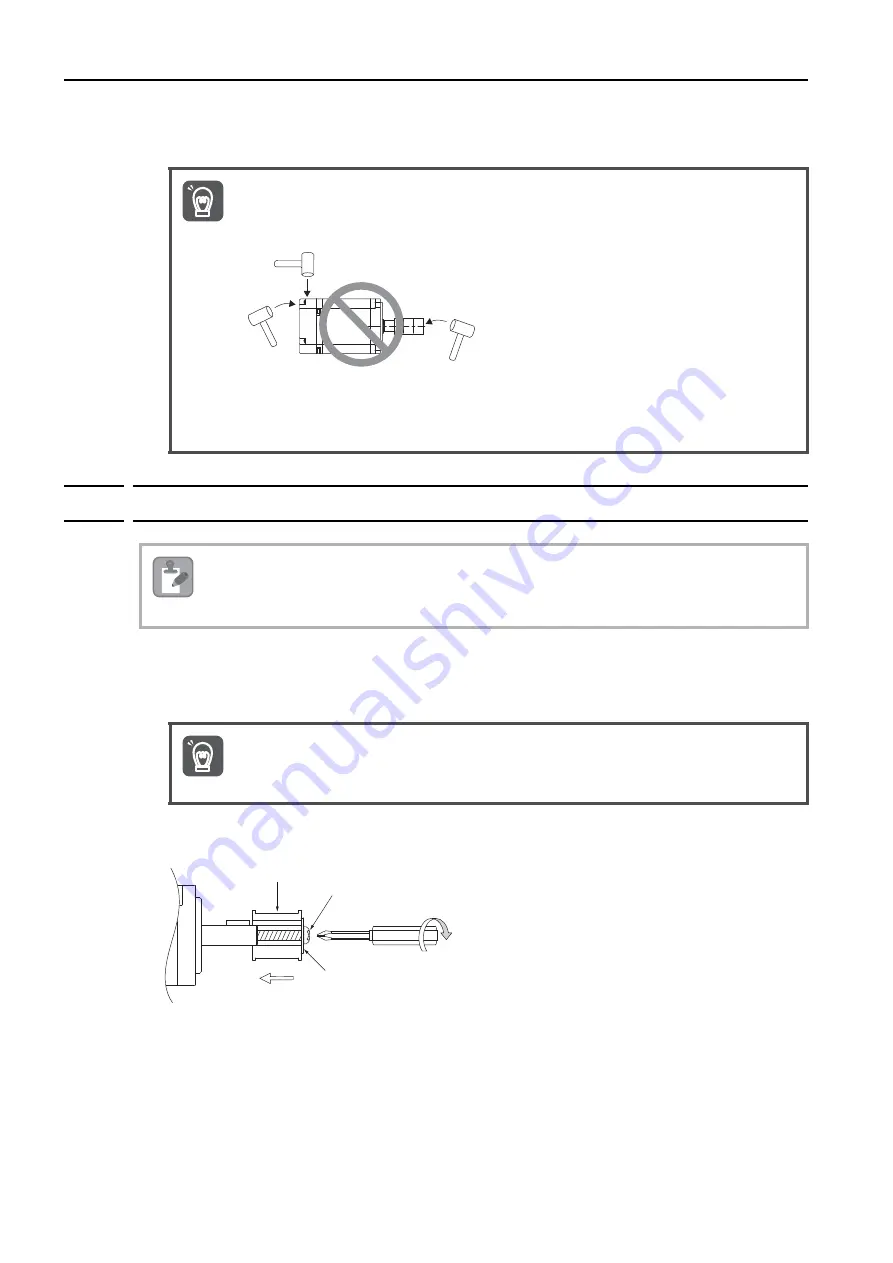

If you need to attach a pulley to the Servomotor with a Key, use a screwdriver to tighten

the screw in the end of the motor shaft to press in and attach the pulley.

•

When you couple the shafts, make sure that the required centering accuracy is achieved.

Vibration will damage the bearings and encoders if the shafts are not properly centered.

•

When you attach the coupling, do not subject the shaft to direct shock. Also, do not sub-

ject the area around the encoder to shock. Shock may damage the encoder.

•

If the coupling makes any abnormal noise, center the shafts again until the noise is elimi-

nated.

•

Make sure that the thrust load and radial load are within specifications. Refer to the spec-

ifications for each type of Servomotor for the thrust load and radial load.

Important

Select a coupling belt that is suitable for the allowable radial load of the Servomotor and the Ser-

vomotor output. When the Servomotor accelerates or decelerates, the counterforce from the

acceleration/deceleration torque adds tension to the initial belt tension. Take this additional ten-

sion into consideration when you select the coupling belt.

When you attach the key to the motor shaft, do not subject the key groove or shaft to direct

shock.

Note

Important

Pulley

Screw

Washer