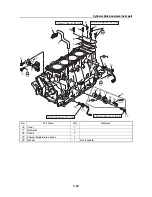

Crankcase, connecting rod, and piston

5-80

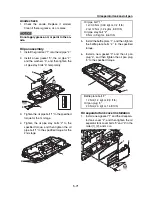

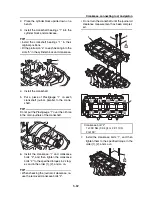

6.

Before installing the connecting rod onto

the crankshaft, assemble the connecting

rod, which the connecting rod bearings

were installed in step 2, to the crankshaft

kept in the current condition.

TIP:

Tighten the connecting rod bolts while check-

ing that the sections shown “a” and “b” are

flush with each other by touching the surface.

7.

Tighten the connecting rod bolts to the

specified torque.

8.

Loosen the connecting rod bolts, remove

the connecting rod and connecting rod cap

and install these parts to the crankshaft

with the connecting rod bearings kept in

the current condition.

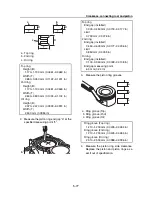

TIP:

• Make sure that the “Y” mark “a” on the con-

necting rod faces toward the timing chain

drive gear “b” of the crankshaft.

• After installation, check that the section “c” is

flush by running your finger across the sur-

face.

• Do not turn the connecting rod or crankshaft

until the crankshaft pin oil clearance mea-

surement has been completed.

9.

Tighten the connecting rod bolts to the

specified torques in 2 stages.

10. Remove the connecting rod cap and mea-

sure the width “a” of the compressed Plas-

tigauge on each crankshaft pin. Replace

the connecting rod bearings if out of spec-

ification.

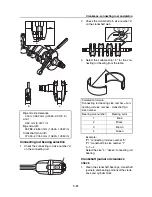

Connecting rod big end side

clearance check

1.

Measure the connecting rod big end side

clearance “a”. Measure the connecting rod

big end width “b” and crankshaft pin width

“c” if out of specification.

Connecting rod bolt

30 Nm (3.0 kgf·m, 22.1 ft·lb)

a

b

Connecting rod bolt

1st: 51 Nm (5.1 kgf·m, 37.6 ft·lb)

2nd: 90°

Pin oil clearance

0.020–0.056 mm (0.0008–0.0022 in)

Limit

0.09 mm (0.0035 in)

YH

c

b

a

a

Summary of Contents for Waverunner VXS VX1800

Page 1: ...SERVICE MANUAL WaveRunner VXS VX1800 F2W VXR VX1800A F2W F2W 28197 ZU 11 ...

Page 12: ...How to use this manual 1 7 UP Upside YDIS Yamaha Diagnostic System Abbreviation Description ...

Page 40: ...Technical tips 1 35 MEMO ...

Page 163: ...Oil separator tank and oil pan 5 72 3 4 4 4 4 4 9 4 1 5 6 10 11 7 2 3 8 ...

Page 180: ...Crankcase connecting rod and piston 5 89 MEMO ...

Page 204: ...6 23 Intermediate housing Intermediate housing bolt 2 17 Nm 1 7 kgf m 12 5 ft lb 1 2 3 ...

Page 205: ...Intermediate housing 6 24 MEMO ...

Page 251: ...Indication system 7 44 MEMO ...

Page 278: ...8 25 Exhaust system 6 Install the band Rubber hose clamp 2 3 5 Nm 0 35 kgf m 2 58 ft lb ...

Page 290: ...Deck and hull 8 37 MEMO ...

Page 312: ...Engine unit troubleshooting 9 21 MEMO ...

Page 313: ...A Appendix Wiring diagram A 1 How to use the wiring diagram A 1 VXS VXR A 2 ...

Page 317: ......

Page 318: ...Mar 2015 CR E ...