8

1

)

When filling the delivery piping with material for the first time, the air inside the piping will blow out. Please follow

the following procedure.

①

Put a plastic bag over the material outlet to receive discharged material.

②

Open the valve on the delivery piping.

③

Open the air valve for the pump and set the pump air regulator for minimum operating pressure.

④

The pump will start discharging material from the outlet. Once the air in the piping is released completely,

close the air valve for the pump and set the pump air regulator to 0MPa.

⑤

The pump is now ready for operation.

2

)

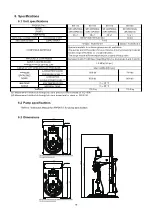

Adjust the pump air regulator to set to the desirable operating pressure. An estimate of the material discharge

pressure to the supply air pressure is calculated by “supply air pressure × pump ratio”.

(e.g. When operating a 38:1 ratio pump at 0.7MPa supply air pressure, material will be discharged at approx.

26.6MPa.)

<NOTE>

Material viscosity changes with seasons. It is recommended to make a note of appropriate pressure for each

season.

3.4 Replacement of drum

CAUTION

-

Do not try to separate the inductor plate from a drum at once with the “PRESS” button depressed.

Compressed air built up inside a drum may be released causing a spurt of residual material.

1

)

When a drum becomes empty, the pump will run dry and NOT stop automatically. Close the pump air valve and

adjust air pressure to 0MPa using the pump air regulator.

2

)

Verify that the lift control switch is set to “DOWN” and the air release plug on the inductor plate is closed.

3

)

Keep holding the “AIR” button until the inductor plate reaches 10cm below the point where it is separated from a

drum. The inductor plate sometimes separates automatically from a drum. If it doesn’t, press and release the

“AIR” button repeatedly to separate the inductor plate gradually from a drum.

4

)

Once the inductor plate is separated from a drum, turn the switch to “UP” to raise the lift to the upper limit.

5

)

Set a new drum according to the procedure described in “3.2 Placement of drum”.

3.5 After work

CAUTION

-

After work or when shutting down the unit for a long period, be sure to turn off the air supply source

to disconnect air supply to the pump, and open the valves on the material outlet or gun to release

residual pressure inside the pump and piping. Failure to shut off air may cause damage to the hoses

and pipes and/or leak in the valves and gun. Any secondary accidents caused by the failure

mentioned above are the responsibility of the users.

1

)

Close the air valve for the pump and set the pump air regulator to 0MPa.

2

)

Adjust the lift control switch to “DOWN”.