11

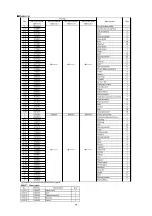

PROBLEM

POSSIBLE CAUSE

REMEDY

Compressor is off.

Turn on compressor.

Valve on air piping is closed.

Open valve.

Air pressure setting is under 0.2MPa.

Set air pressure to 0.2MPa or above.

Valve on material outlet is closed.

Open valve.

Frost occurs inside silencer.

Use dry air.

O ring on sliding part of air piston is worn out.

(Air leak occurs from silencer.)

Block (773210) and ball (686271) in valve body (804815) are worn out.

Any parts (e.g. spring, pin) used in switching system in valve body (804815) or

air motor (804814 / 804856) are damaged.

Air leak from air

motor

- Fasteners are loose.

- O rings and packings are worn out.

- Retighten loose parts.

- Replace worn part.

Air leak from

silencer during

shutdown

- Foreign object is caught between block (773210) and valve seat (716246) in

valve body (804815).

- Seating part is worn out.

- Remove foreign object.

- Replace worn part.

Pump doesn’t run

and air leaks from

silencer

- Foreign object is caught between spindle (716299) and valve switcher

(832996) in air motor (804814 / 804856).

- There exists damage that prevents sliding movement of parts below.

- Remove foreign object.

- Replace worn part.

Pump doesn’t draw

material at first time

of operation

Pump operating speed is so fast that lower pump suction cannot keep up with

pump movement. (Valve inside lower pump is not working well.)

Set pump speed to 5-8 sec. per cycle

until material is pumped out.

If upward movement of plunger is faster,

- seat surface of piston valve is defective (wear of seat surface, inclusion of

foreign material) or,

- packings are damaged.

If downward movement of plunger is faster,

- seat surface of foot valve is defective (wear of seat surface, inclusion of foreign

material),

- packings are damaged, or

- shovel rod is bent.

If downward movement of plunger is faster, operating speed is so fast that lower

pump suction cannot keep up with pump movement. (Vacuum is caused inside

lower pump.)

Decrease air pressure until material

comes out. (This pressure is the

upper limit of normal operating

pressure.)

Connecting rod connecting air motor and lower pump is completely separated

from air motor. (In this case, parts inside of lower pump may be damaged.)

Inspect inside lower pump first, then

replace damaged part, and retighten

each part.

Leak occurs in delivery pipe.

Leak occurs in lower pump (connections are loosened or o ring, backup ring, or

packing is damaged).

Material leak from

lower pump

- Fasteners are loose.

- O ring, backup ring, or packing is damaged.

- Retighten loosened parts.

- Replace damaged part.

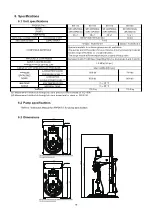

Internal diameter of drum is larger than specified.

Use the drums described in the

“6.Specifications”.

Air release plug is loosened.

Secure air release plug.

Packing of inductor plate is deteriorated.

Replace packing.

- Fasteners are loosened.

- O ring or backup ring is damaged.

- Retighten loosened parts.

- Replace damaged part.

Internal diameter of drum is larger than specified.

Use the drums described in the

“6.Specifications”.

Drum surface is uneven.

Use straight side drum.

Packing of inductor plate is deteriorated.

Replace packing.

Compressor is off.

Turn on compressor.

Air supply is off.

Turn on air supply.

Valve on air piping is closed.

Open valve.

Air pressure setting is not enough.

Set air pressure to 0.4MPa.

Drum surface is uneven.

Use straight side drum.

Cylindrical section of lift air cylinder is dent.

Replace part.

Foreign object is caught in sliding part of lift.

Foreign object is caught in slider roller of lift rail.

Drum raises

together with lift

Lift control switch is adjusted to “UP”.

Adjust switch to “DOWN”.

Lift control switch is adjusted to “STOP”.

Adjust switch to “DOWN”.

Air release plug on inductor plate is not secured.

Tighten air release plug.

Lift doesn’t raise

with AIR button

Lift doesn’t move

up/down

- Retighten loosened parts.

- Replace damaged part.

Material leak

around inductor

plate

Pump doesn’t stop

- Remove foreign object.

- Replace worn part.

Pump doesn’t run

Remove foreign object.

Replace worn out or damaged part.

Material cannot be

pumped out

Material contains

air bubbles even

after bleeding

4.2 Troubleshooting

If you suspect that you have a problem with your product, consult the table below for some common problems

and their solutions. Contact the retail store where you purchased your product or our business office if all else

fails.