12

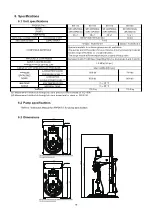

Application

Pumping and transferring grease

Season

Spring and Fall

Temperature

20°C

Material being pumped

Lithium Soap Grease: No.1

Container

JIS Z 1600 Open Head Steel Drums, Drum type D (208L)

Operating pressure for lift

0.4MPa

Daily Amount of Material being pumped

1 drum

Operating Days per year

260 days (5 days a week)

Standard Conditions of Use for Lift and Inductor Plate

4.3 Consumables

1

)

Pump

Refer to “Instruction Manual for APP067U” for replacement time for consumables used in the pump. The

replacement time should be used only as a guide. Consumption varies depending on use conditions. Also, be

sure to replace a part when you find any defect like a leak during operation.

2

)

Lift

- The plastic tubes will be degraded naturally. Replace them all every six years.

- The switches and regulators should be replaced if you find they are not working properly. Never use a

defective device.

3

)

Inductor Plate

- The wiper will get worn out due to sliding contact with a drum. Considering natural degradation, replace it

every six years.

- The gasket used for the connection between the pump and inductor plate will get worn out by repetitive

mounting and removal of the inductor plate. Replace it with a new one when it is damaged at the time of

inductor plate removal.

4.4 Design standard use period

Design standard use period is established for the product. (See the table below.)

Use of the product beyond this period may result in personal injury or property damage.

- Pump

…

Refer to “Instruction Manual for APP067U”.

- Lift and inductor plate

…

10years