6

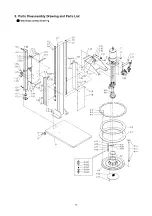

3.1

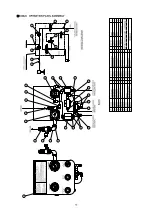

Description of control and valve

(

Refer to “Fig. 1 Part names” and “Fig. 2 Part names of operation panel”

)

- Pump Air Regulator

Function : Controlling air pressure for pump operation.

To operate : Clockwise turn will increase pressure. Counterclockwise turn will decrease pressure.

(It can be locked by pushing the knob in.)

Note

: The maximum allowable operating pressure of the pump is 0.7MPa. DO NOT exceed this limit.

Remark

: Discharge pressure can be calculated by multiplying the air pressure by the pump ratio.

- Air Valve, Pump (ball valve attached to the right side of pump air control)

Function : Starting/Stopping the pump.

To operate : When the lever is parallel to the pipe, the valve is open. If the lever is perpendicular to the pipe, the

valve is closed.

Note

: In case of emergency, close the emergency stop valve attached to the air piping instead of this

valve.

- Lift Air Regulator

Function : Controlling air pressure for lift and inductor plate operation.

To operate : Clockwise turn will increase pressure. Counterclockwise turn will decrease pressure.

(It can be locked by pushing the knob in.)

Note

: Set the normal operating air pressure to 0.4MPa.

- Lift Control switch (UP/DOWN/STOP)

Function :

Raising/Lowering/Stopping the lift. While moving up by air pressure, the lift moves down by its own

weight. In the “STOP” mode, air supply is turned off and the lift stops in a balanced position by

residual pressure. The lift speed is maintained at a constant level by the throttle valves attached on

the air inlet of the air cylinder of the lift.

To operate : Adjust the switch to each position depending on the intended use.

- PRESS button, Lift

Function : Setting the inductor plate in a drum and filling the inductor plate with material.

To operate : Push the button while the lift control switch is “DOWN”. It functions only when the “Press” button is

depressed. Keep holding the button as long as you need. Note that this button doesn’t work unless

the lift control switch is set to “DOWN”.

- AIR button, Inductor Plate

Function : Separating the inductor plate from a drum when a drum becomes empty.

To operate : Air is supplied as long as the button is depressed.

Note

: Pressing the button when a drum is not empty may be a cause of air bubbles in material.

- Bleeder Valve

Function : Removing air from the pump and inductor plate after setting the inductor plate in a drum.

To operate : Holding the hexagonal head with a wrench (13mm), counterclockwise turn will open the valve.

Clockwise turn (all the way) will close the valve. 3-4 turns will be enough for bleeding.

Note

: Be sure to close the valve securely after releasing air.

- Air Release Plug

Function : Removing air from the pump and inductor plate when setting the inductor plate in a drum. Open the

plug before inserting the inductor plate into a drum and close it once material comes out of the air

release hole.

To operate : Open and close by turning the plug holding the knurled part on the top by hand. Left turn will loosen

the plug. Right turn will tighten the plug. Be sure to securely turn it when closing (tightening).