9

4. Maintenance and inspection

CAUTION

-

Be careful not to allow the pump and lift to accidentally operate during maintenance and inspection.

-

When performing maintenance or inspection, notify workers by hanging a sign or other method to

keep them from touching the unit.

-

Gasoline is a high volatile fuel. Never use it for cleaning of the unit. Risk of fire or explosion may

exist.

4.1 Maintenance and inspection

INTERVAL ACTION

Daily

①

Inspect operation of pump.

②

Inspect operation of lift.

Weekly

③

Lubricate pump. (turbine oil, class#1, additive-free: ISO V 32)

Annually

④

Check for loose bolts and nuts.

⑤

Clean and lubricate lift rail. (lithium soap base grease: No.1)

Triennially

⑥

Overhaul pump.

①

Inspect operation of pump

Inspect pump to ensure the following:

- The pump operates normally and smoothly,

- There is no air/material leak in each part of the pump or air/material

piping,

- There is no abnormal noise during pump operation, and

- There is no abrasion or deterioration apparently in each part of the

pump.

②

Inspect operation of lift

Inspect lift to ensure the following:

- The lift operates normally and smoothly,

- There is no air leak in air piping of the lift,

- There is no abnormal noise during lift operation, and

- There is no abrasion or deterioration apparently in each part of the lift.

- When the unit moves, shaking isn't big. (Compared with the beginning)

③

Lubricate pump

Lubricate pump according to the following procedure:

- Close the air valve for the pump and set the pump air regulator knob to

0MPa.

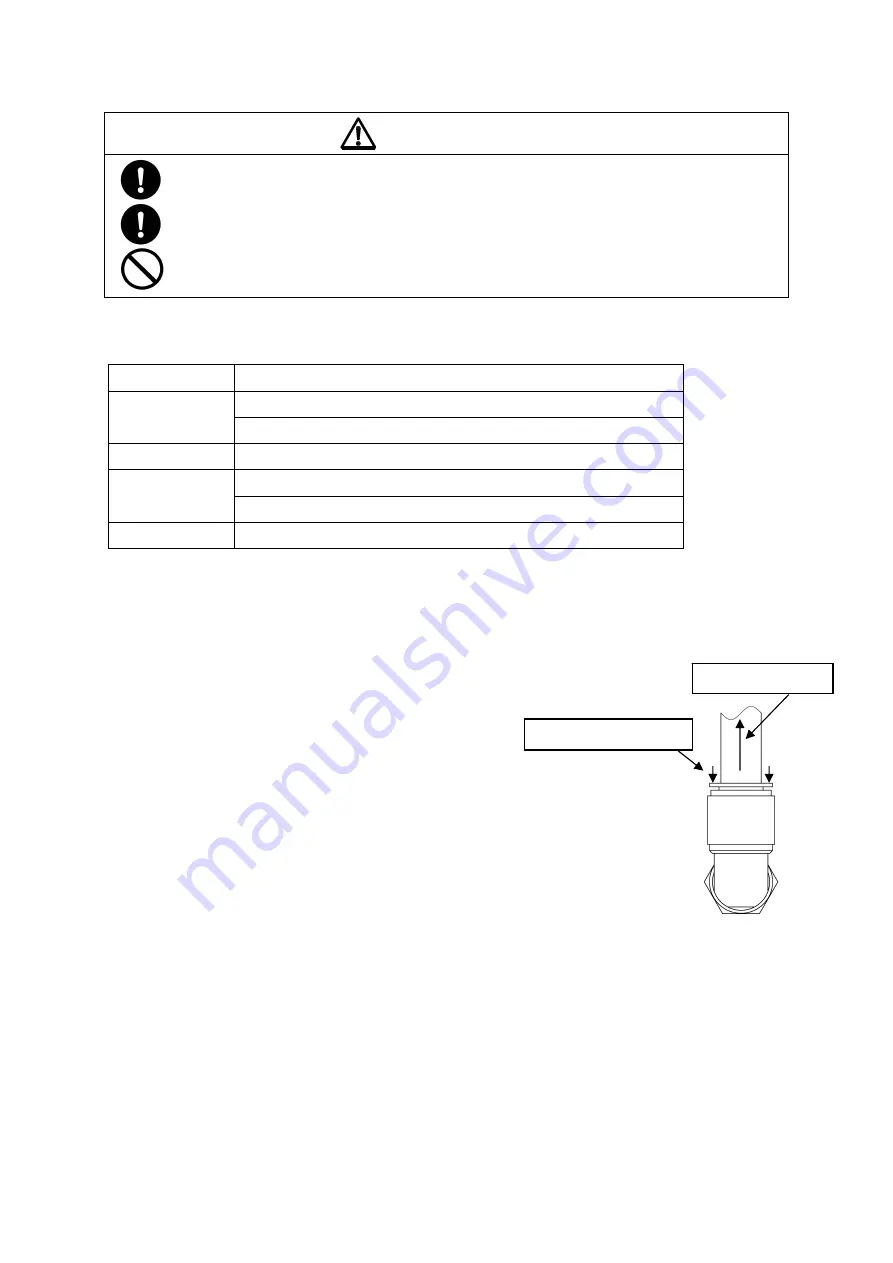

- Disconnect a tube from fitting on the air inlet. (Fig. 9)

- Apply a few drops of lubricant oil (turbine oil, class#1, additive-free: ISO

VG 32) to the port of the fitting from which the tube has been

disconnected.

- Reinsert the tube all the way into the fitting. Then, pull it to ensure it is

securely connected.

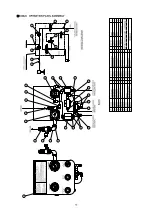

Fig. 9

Removal of tube

②

Pull out the tube.

①

Keep pushing the lip.