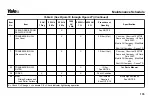

Table 8. (See Figure 18 through Figure 27) (Continued)

Item

No.

Item

8 Hr/

1 Day

250 Hr/

6 Mo

500 Hr/

6 Mo

1000

Hr/

6 Mo

2000 Hr/

1 Yr

4000 Hr/

2 Yr

Procedure or

Quantity

Specification

NOTE 1: Check fuel system for leaks prior to any service or maintenance activity.

NOTE 2: Heavy-duty or high-temperature operations require more frequent checks.

NOTE 3: Heavy-duty or contaminated applications will require hydraulic oil change at 2000 hours.

NOTE 4: Change engine oil and filter after the first 100 hours of operation. Change transmission oil filter after first 500 hours of operation.

NOTE 5: Recommended service intervals are based on a normal application in a clean environment. Applications involving contaminated environments

such as high levels of airborne debris (dust and waste paper); chemical or abrasive compounds; poor ground conditions; intensive usage at high perform-

ance levels; or other abnormal conditions will require more frequent servicing. At your request, your

Yale

dealer will advise you of the appropriate service

intervals based on an application survey.

NOTE 6: In dirty or dusty environments, replace at 1000 hours or as needed.

NOTE 7: Replace timing belt on Mazda engines every 3500 hours. Use only hour interval.

NOTE 8: Check fuel injectors at 5000 hours or 7 years.

NOTE 9: Multipurpose grease with 2 to 4% Molybdenum Disulfide.

NOTE 10: Lubricate mast every 3 months if unit has less than 1000 hours.

NOTE 11: Lubricate at first sign of visible surface rust.

NOTE 12: Do not open the air filter canister except to change the air filter element. See the Periodic Maintenance Manual for your lift truck for the correct

procedure to change air filter element.

X = Check C = Change L = Lubricate CIL = Check indicator light during operation

Maintenance Schedule

139

Summary of Contents for VERACITOR GCC030VX

Page 24: ...Figure 6 Display Switch Cluster Right Side Display Inputs Model Description 22...

Page 40: ...Figure 8 Operator Controls Sheet 2 of 2 Model Description 38...

Page 83: ...Figure 13 Seat Adjustment Full Suspension Operating Procedures 81...

Page 172: ...Figure 43 LPG Tank and Bracket Maintenance 170...