80

10

1. Opis funkcij

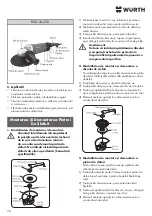

1. Kako namestiti brusno ploščo

Vedno izklopite napravo na

stikalu in iz električne napetosti

pred namestitvijo ali zamenjavo

brusilnega orodja. Ne uporabljajte

brusilnega orodja, ki je neprimerno

ali preveliko za napravo.

1. Obrnite kotni brusilnik z vretenom navzgor. Namestite

zatezno podložko na vreteno.

2. Na zatezno podložko namestite brusilno orodje.

3. Namestite zatezno matico na vreteno.

4. Pritisnite zaklep obračanja vretena in s ključem dobro

zategnite zatezno matico s ključem.

5. Za menjavo brusilnega orodja, postopek izvedite v

obratnem vrstnem redu.

OPOZORILO! Namestiti morate

zaščitno orodje in vedno nositi

zaščitna očala med uporabo

električnega orodja.

2. Kako namestiti brusni papir

Ne smete uporabiti iste zatezne matice in zatezne

podložke za uporabo

1. Obrnite kotni brusilnik z vretenom navzgor. Namestite

gumijasto podložno ploščo na vreteno.

2. Na gumijasto podložno ploščo namestite brusni papir.

3. Namestite zatezno matico na vreteno.

4. Pritisnite zaklep obračanja vretena in s ključem dobro

zategnite zatezno matico s ključem.

5. Za menjavo brusilnega orodja, postopek izvedite v

obratnem vrstnem redu.

2. Namen naprave

• Rezanje, brušenje in poliranje železa,

jekla, aluminija in ulitkov.

• Brušenje po varjenju in odstranjevanje

oksidacije.

• Brušenje in poliranje plastike, opeke,

ploščic in kamna.

6. Opis funkcij in namena naprave

7. Namestitev in zamenjava orodja

18

2. List of contents

1. Description of functions

1. Noise emission

Noise emission values determined according to EN

60745.

2. The operator to wear hearing protection

3. Vibration emission

Vibration total values (triaxial vector sum) determined

according to EN 60745

4. The following information

The declared vibration total value has been measured

in accordance with a standard test method given in

EN 60745 and may be used for comparing one tool

with another.

The declared vibration total value may also be used in

a preliminary assessment of exposure.

5. A warning

The vibration emission during actual use of the power

tool can differ from the declared total value

depending on the ways in which the tool is used.

Identify additional safety measures to protect the

operator that are based on an estimation of exposure

in the actual conditions of use (taking account of all

parts of the operating cycle such as the times when the

tool is switched off and when it is running idle in

addition to the trigger time).

1. Specifications

Noise and Vibration Emissions

Specifications and List

of Contents

Check before Use

Description of Functions and

Applications

EAG 20-230

EAG 24-230

EAG 20-230 EAG 24-230

8.5 m/s²

2.0 m/s²

1.5 m/s²

4.5 m/s²

Vibration emission value (a )

h

Vibration emission value (a )

h

Uncertainty (K)

Uncertainty (K)

Grinding mode

Disk-type sanding mode

Items

Rated speed

Model

Power source

Motor

Weight (witout cord)

Cord

A Type : AC 110-127 V 50/60 Hz

~

B Type : AC 220-240 V 50/60 Hz

~

Single phase series commutator series motor

15 A

2000 W

110-127V

220-240V

2400 W

230x6x22.23

n

6500 /min

2-core cabtyre cord

4.3 kg

4.9 kg

M 14

Spindle Thread

Protection Class

Size of grinding stone

(outsize dis. x thick x minor dia. mm)

Rated curent (A)

Rated input (W)

Grinding stone

Model

Items

Spanner

Carbon brush

Side handle

D handle

Optional

Optional

Optional

Optional

Optional

EAG 20-230

Stopper

Handle

Trigger switch

Brush cap

Wheel guard

Side handle

Grinding Stone

Lock pin

EAG 24-230

Grinding Stone

Handle

Lock pin

Trigger switch

Stopper

Handle Lock

Damper

Brush cap

Side handle

Wheel Guard

The A-weighted emission sound

level (L )

pA

level (L )

wA

The A-weighted emission sound power

Uncertainty (K)

pressure

89 dB(A)

103 dB(A)

3 dB

Ročaj

Ročaj

Zatič

Zatič

Stikalo

Stikalo

Zavora

Zavora

Pokrov krtačk

Pokrov krtačk

Blažilec

Zaklep ročaja

Brusna plošča

Brusna plošča

Stranski ročaj

Stranski ročaj

Zaščitna obroba

Zaščitna obroba

19

3. How to install and remove the flexible

grinding stone

You can use the same wheel nut and wheel washer that

used for the grinding stone.

1) Set the wheel washer of the spindle as the installing of

the grinding stone. And then, set the pad and flexible

grinding stone one by one.

2) Set the wheel nut to the spindle above the flexible

grinding stone.

3) Fix the axis of the spindle by pressing the lock pin. And

then, fasten the wheel nut with a spanner tightly.

4) Do the same process reversibly to remove the sanding

disc.

1. Avoid excessive pressure on the grinding

stone

Avoid excessive pressure on the grinding stone.

Grinding is done by tool's weight. Apply the grinding

stone lightly to the work.

Excessive pressure on the grinding stone will decrease

grinding speed and cause rough finishing surface. Also,

it may cause overheating and motor failure.

2. Applications

To do finishing work and removing splinters of iron,

bronze, aluminum, cast.

To grind of welding section part and removing rust.

To do finishing work for the surface of synthetic resin,

slate, brick and marble.

To groove and cut tile and stone.

1. How to install and remove the Grinding Stone

Always turn off the switch and

disconnect the plug from the power

supply before installing and removing

grinding stone. Never use the grinding

stone below the peripheral velocity (See

to specifications).

Installing and Removing

1) Place the spindle upwards. Insert the depressed part of

the wheel washer onto the plane part of the spindle.

2) Place the prominent part of the grinding stone onto the

wheel washer.

3) Set the wheel nut onto the spindle over the grinding

stone by a screw.

4) Insert the lock pin in the gear cover, then fasten the

wheel nut with the spanner.

Warning

You must install the wheel guard and

wear the safety goggles during using of

the disc grinder with the special parts.

2. How to install and remove the sanding disc

Do not use the wheel washer and wheel nut for the

grinding stone. Please use other washer nut for the

sanding disc.

1) Set the rubber pad and sanding disc to the spindle.

2) Set the washer nut to the spindle above the sanding disc.

3) Fix the spindle by pressing the lock pin with fingers. And

then, fasten the washer nut with a spanner tightly.

4) Do the same process reversibly to remove

the sanding disc.

Operating Instructions

Spanner

Fastening

Projection

Lock pin

Wheel

guard

Wheel

washer

Grinding

stone

Wheel nut

Spindle

Spanner

Spanner

Fastening

Fastening

Sanding

disc

Flexibile

grinding stone

Rubber

pad

Pad

Lock pin

Lock pin

Washer

nut

Wheel

washer

Wheel

nut

17

Check before Use

2. The extension cord

When the power source is located far from your

location, you may use the extension cord. However, you

should use the extension cord with proper length and

thickness not to prohibit the current. When you use too

long or thin extension cord, the voltage drop will be

higher. In result, the power of the motor will be

decreased. Please use the shortest extension cord

possible.

When the extension cord is damaged,

you must change or repair it

immediately.

3. The power source

You must use the tool in the power source specified in

the nameplate. When you use the tool for 110V in

220V/230V, the speed of the motor will be increased

abnormally. In result, the grinding stone and the tool

may be damaged.

When you use the tool for 110V in

220V/230V, the motor can be damaged

by a fire.

4. The switch

When you plug in the power source with

the tool switched on, you may be injured

seriously by sudden rotating of the tool.

Make sure the switch lever is returned to its original

position by pushing or pulling it.

5. The wheel guard

The wheel guard is a protective wall

preparing for the damage of the

grinding stone. You must install the

wheel guard.

You can set the desired angle of the wheel guard by

unfastening two small screws. Please use the tool after

adjusting the angle of the wheel guard for the work.

After adjustment, please fasten two small screws tightly.

6. Checking and installing the grinding stone

Be sure the grinding stone is in normal

condition and free from cracks or

damage. Make sure the grinding stone is

installed securely. To install the grinding

stone, see to the section installing and

removing grinding stone.

7. Mains Outlet

When inserting the plug, if a sound is heard or if it is a

taken out easily, you must repair it. Please contact

nearby electric shop.

When you use the mains outlet as it is, it causes the

accident by overheating.

8. Trial run

Always make a trial run before operation with grinding

stone pointed away from people to check the tool.

Before switching on the disc grinder, be

sure the rotating part of the disc grinder

is not contacted work material.

Accidental switching on with contacted

other objects may cause personal injury

by damaged grinding stone.

9. An explanation of any symbols or

pictograms marked on the tool relevant to

safe use

10. Product type

Nominal cross

section of

conductor

1.0 mm²

1.5 mm²

2.5 mm²

Nominal cross

section of

conductor

1.0 mm²

1.5 mm²

2.5 mm²

Max.

lenght

10 m

15 m

25 m

Max.

lenght

20 m

30 m

50 m

110-120 V

220-240 V

Trial run time

When replacing grinding stone

When using grinder initialy

3 minutes or more

1 minute or more

n

V

A

Hz

W

/min

~

rated speed

volts

amperes

hertz

watts

Handle

Only

plastic

Soft-

starter

Restart-

pro

Soft-starter

plastic

+

rubber

Lock-off

(2pole,

2 terminal)

Lock-on

(2pole,

2 terminal)

Lock-on

(1pole,

4 terminal)

Switch

Controller

Product

TYPE 1

TYPE

TYPE 2

TYPE 3

TYPE 4

TYPE 5

TYPE 6

TYPE 7

TYPE 8

revolutions or reciprocations per minute

alternating current

Class II construction

Disposal of Old Electrical &

Electronic Equipment

1. Connection to Power Supply

[110-120 V ]

[220-240 V ]

~

~

17

Check before Use

2. The extension cord

When the power source is located far from your

location, you may use the extension cord. However, you

should use the extension cord with proper length and

thickness not to prohibit the current. When you use too

long or thin extension cord, the voltage drop will be

higher. In result, the power of the motor will be

decreased. Please use the shortest extension cord

possible.

When the extension cord is damaged,

you must change or repair it

immediately.

3. The power source

You must use the tool in the power source specified in

the nameplate. When you use the tool for 110V in

220V/230V, the speed of the motor will be increased

abnormally. In result, the grinding stone and the tool

may be damaged.

When you use the tool for 110V in

220V/230V, the motor can be damaged

by a fire.

4. The switch

When you plug in the power source with

the tool switched on, you may be injured

seriously by sudden rotating of the tool.

Make sure the switch lever is returned to its original

position by pushing or pulling it.

5. The wheel guard

The wheel guard is a protective wall

preparing for the damage of the

grinding stone. You must install the

wheel guard.

You can set the desired angle of the wheel guard by

unfastening two small screws. Please use the tool after

adjusting the angle of the wheel guard for the work.

After adjustment, please fasten two small screws tightly.

6. Checking and installing the grinding stone

Be sure the grinding stone is in normal

condition and free from cracks or

damage. Make sure the grinding stone is

installed securely. To install the grinding

stone, see to the section installing and

removing grinding stone.

7. Mains Outlet

When inserting the plug, if a sound is heard or if it is a

taken out easily, you must repair it. Please contact

nearby electric shop.

When you use the mains outlet as it is, it causes the

accident by overheating.

8. Trial run

Always make a trial run before operation with grinding

stone pointed away from people to check the tool.

Before switching on the disc grinder, be

sure the rotating part of the disc grinder

is not contacted work material.

Accidental switching on with contacted

other objects may cause personal injury

by damaged grinding stone.

9. An explanation of any symbols or

pictograms marked on the tool relevant to

safe use

10. Product type

Nominal cross

section of

conductor

1.0 mm²

1.5 mm²

2.5 mm²

Nominal cross

section of

conductor

1.0 mm²

1.5 mm²

2.5 mm²

Max.

lenght

10 m

15 m

25 m

Max.

lenght

20 m

30 m

50 m

110-120 V

220-240 V

Trial run time

When replacing grinding stone

When using grinder initialy

3 minutes or more

1 minute or more

n

V

A

Hz

W

/min

~

rated speed

volts

amperes

hertz

watts

Handle

Only

plastic

Soft-

starter

Restart-

pro

Soft-starter

plastic

+

rubber

Lock-off

(2pole,

2 terminal)

Lock-on

(2pole,

2 terminal)

Lock-on

(1pole,

4 terminal)

Switch

Controller

Product

TYPE 1

TYPE

TYPE 2

TYPE 3

TYPE 4

TYPE 5

TYPE 6

TYPE 7

TYPE 8

revolutions or reciprocations per minute

alternating current

Class II construction

Disposal of Old Electrical &

Electronic Equipment

1. Connection to Power Supply

[110-120 V ]

[220-240 V ]

~

~

Zatezna matica

Brusna

plošča

Zatezna

podložka

Zaščitna

obroba

Ključ

Smer

Zatič

Vreteno

Smer

zategovanja

11

1. Izogibajte se pretiranemu pritisku na

brusilno orodje

Izogibajte se pretiranemu pritisku na brusilno orodje.

Brušenje se izvaja le s težo brusilke. Pri delu brusilno

orodje uporabljajte zmerno.

Pretiran pritisk na brusilno orodje lahko zmanjša

hitrost obratov in povzroči grobe poškodbe na

obdelovancu. Lahko povzroči tudi pregrevanje in

odpoved motorja naprave.

2. Kot brušenja

Ne uporabljajte celotne površine brusilne plošče. Za

dobro brušenje je dovolj uporaba rob brusilne plošče.

Za efektivno brušenje je primeren kot brusilke med

15°in 30°, kot je prikazano na sliki.

3. Smer brušenja

Ko uporabljate novo brusilno ploščo jo najprej

uporabljajte v smeri proti sebi, da zaobljite rob ploče.

Ko je plošča po robu zaobljena se lahko uporablja v

vse smeri.

Brusilne plošče z grobo granulacijo (granulacija

#36) je najbolj primerna za grobo brušenje na

kovinskih materjalih. Brusilno ploščo uporabljajte

brez pretiranega pritiska za gladko površino. Za

bolj gladko površino in ostale materjale uporabljajte

brusilne plošče višjih granulacij.

4. Opozorila ob koncu uporabe naprave

Izklopite napravo na stikalu za zaustavitev vrtenja.

Napravo shranjujte na varnem mestu.

Če shranjujete napravo, ko se brusilna plošča še

vrti, lahko zajame prah in nevarne dele, kar lahko

povzroči poškodbe naprave.

Kotna brusilka se pri padcu ali udarcu lahko

poškoduje. Če kotna brusilka pade ali utrpi

udarec preverite brusno ploščo in brusilko,

če so nastale poškodbe.

3. Kako namestiti fleksibilno brusilno ploščo

Uporabite lahko iste zatezne matice in zatezne

podložke za uporabo

1. Obrnite kotni brusilnik z vretenom navzgor. Namestite

podložno ploščo na vreteno.

2. Na podložno ploščo namestite brusni papir.

3. Namestite zatezno matico na vreteno.

4. Pritisnite zaklep obračanja vretena in s ključem dobro

zategnite zatezno matico s ključem.

5. Za menjavo brusilnega orodja, postopek izvedite v

obratnem vrstnem redu.

8. Navodila za uporabo

20

2. Pressing angle

Do not press the whole surface of the grinding stone to

the grinding surface. It is recommended to use the disc

grinder by inclining it in 15-30 degrees as the picture to

do grinding work with circumference of the grinding

stone.

3. Grinding direction

When using a new grinding stone, be certain to grind

while pulling tool backwards (B direction) until the

grinding stone becomes rounded on its edge. Then, the

grinder can be moved to any direction.

This grinding stone (Grinding particle: A, Mesh: #36) is

best for heavy grinding in general steel materials. Also,

it can be used in wide range of other materials. For its

lower mesh, apply the grinding stone to the work

material lightly and grind steadily to create smooth

finishing surface that can be made by the grinding stone

with higher mesh.

4. Caution after use

Switch off to stop the rotation of the grinding stone, and

keep the disc grinder in safe place.

When you keep the disc grinder with the grinding stone

rotated in the place filled with dust and shavings, dust

and shavings can be gotten into the disc grinder.

The grinding stone can be cracked or

grooved by an impact. Please take care

not to impact on the disc grinder. If the

disc grinder is hit against something or

fallen down, you must check the

grinding stone and disc grinder.

5. How to rotate the head of the disc grinder

Remove the plug from plug socket before any operation.

For the above purpose, rotate the head of the disc

grinder in a 90-degree turn instead of rotating the

handle. And then, unscrew four screws and the head.

Do not remove the head from the main body wholly but

rotate to new position. After that, set four screws and

fasten them.

20

6. How to rotate the handle of the disc grinder

Disconnect the plug from the power

supply before making any maintenance.

1. Change of the grinding stone

Please change the grinding stone with new one when

outer diameter of the grinding stone in 180mm is worn

to

100mm

(For

the

grinding stone in 230mm is

130mm).

2. Screws

Make sure screws in each part are set tightly at regular

intervals. When screws are loose, fasten them tightly.

The loose screw causes the danger situation.

3. Carbon brush

Disposable carbon brush is used in the motor. The

heavily worn carbon brush causes the trouble of the

motor.

When the length of the carbon brush is reached at the

wear tolerance line, change it with new carbon brush.

Also, keep the carbon brush clean to be moved in the

brush holder freely.

Maintenance

Side handle

19

3. How to install and remove the flexible

grinding stone

You can use the same wheel nut and wheel washer that

used for the grinding stone.

1) Set the wheel washer of the spindle as the installing of

the grinding stone. And then, set the pad and flexible

grinding stone one by one.

2) Set the wheel nut to the spindle above the flexible

grinding stone.

3) Fix the axis of the spindle by pressing the lock pin. And

then, fasten the wheel nut with a spanner tightly.

4) Do the same process reversibly to remove the sanding

disc.

1. Avoid excessive pressure on the grinding

stone

Avoid excessive pressure on the grinding stone.

Grinding is done by tool's weight. Apply the grinding

stone lightly to the work.

Excessive pressure on the grinding stone will decrease

grinding speed and cause rough finishing surface. Also,

it may cause overheating and motor failure.

2. Applications

To do finishing work and removing splinters of iron,

bronze, aluminum, cast.

To grind of welding section part and removing rust.

To do finishing work for the surface of synthetic resin,

slate, brick and marble.

To groove and cut tile and stone.

1. How to install and remove the Grinding Stone

Always turn off the switch and

disconnect the plug from the power

supply before installing and removing

grinding stone. Never use the grinding

stone below the peripheral velocity (See

to specifications).

Installing and Removing

1) Place the spindle upwards. Insert the depressed part of

the wheel washer onto the plane part of the spindle.

2) Place the prominent part of the grinding stone onto the

wheel washer.

3) Set the wheel nut onto the spindle over the grinding

stone by a screw.

4) Insert the lock pin in the gear cover, then fasten the

wheel nut with the spanner.

Warning

You must install the wheel guard and

wear the safety goggles during using of

the disc grinder with the special parts.

2. How to install and remove the sanding disc

Do not use the wheel washer and wheel nut for the

grinding stone. Please use other washer nut for the

sanding disc.

1) Set the rubber pad and sanding disc to the spindle.

2) Set the washer nut to the spindle above the sanding disc.

3) Fix the spindle by pressing the lock pin with fingers. And

then, fasten the washer nut with a spanner tightly.

4) Do the same process reversibly to remove

the sanding disc.

Operating Instructions

Spanner

Fastening

Projection

Lock pin

Wheel

guard

Wheel

washer

Grinding

stone

Wheel nut

Spindle

Spanner

Spanner

Fastening

Fastening

Sanding

disc

Flexibile

grinding stone

Rubber

pad

Pad

Lock pin

Lock pin

Washer

nut

Wheel

washer

Wheel

nut

19

3. How to install and remove the flexible

grinding stone

You can use the same wheel nut and wheel washer that

used for the grinding stone.

1) Set the wheel washer of the spindle as the installing of

the grinding stone. And then, set the pad and flexible

grinding stone one by one.

2) Set the wheel nut to the spindle above the flexible

grinding stone.

3) Fix the axis of the spindle by pressing the lock pin. And

then, fasten the wheel nut with a spanner tightly.

4) Do the same process reversibly to remove the sanding

disc.

1. Avoid excessive pressure on the grinding

stone

Avoid excessive pressure on the grinding stone.

Grinding is done by tool's weight. Apply the grinding

stone lightly to the work.

Excessive pressure on the grinding stone will decrease

grinding speed and cause rough finishing surface. Also,

it may cause overheating and motor failure.

2. Applications

To do finishing work and removing splinters of iron,

bronze, aluminum, cast.

To grind of welding section part and removing rust.

To do finishing work for the surface of synthetic resin,

slate, brick and marble.

To groove and cut tile and stone.

1. How to install and remove the Grinding Stone

Always turn off the switch and

disconnect the plug from the power

supply before installing and removing

grinding stone. Never use the grinding

stone below the peripheral velocity (See

to specifications).

Installing and Removing

1) Place the spindle upwards. Insert the depressed part of

the wheel washer onto the plane part of the spindle.

2) Place the prominent part of the grinding stone onto the

wheel washer.

3) Set the wheel nut onto the spindle over the grinding

stone by a screw.

4) Insert the lock pin in the gear cover, then fasten the

wheel nut with the spanner.

Warning

You must install the wheel guard and

wear the safety goggles during using of

the disc grinder with the special parts.

2. How to install and remove the sanding disc

Do not use the wheel washer and wheel nut for the

grinding stone. Please use other washer nut for the

sanding disc.

1) Set the rubber pad and sanding disc to the spindle.

2) Set the washer nut to the spindle above the sanding disc.

3) Fix the spindle by pressing the lock pin with fingers. And

then, fasten the washer nut with a spanner tightly.

4) Do the same process reversibly to remove

the sanding disc.

Operating Instructions

Spanner

Fastening

Projection

Lock pin

Wheel

guard

Wheel

washer

Grinding

stone

Wheel nut

Spindle

Spanner

Spanner

Fastening

Fastening

Sanding

disc

Flexibile

grinding stone

Rubber

pad

Pad

Lock pin

Lock pin

Washer

nut

Wheel

washer

Wheel

nut

Zatezna

matica

Zatezna

matica

Brusni papir

Fleksibilna

brusilna plošča

Zatezna

podložka

Gumijasta

podložna

plošča

Podložna

plošča

Ključ

Ključ

Zatič

Stranski ročaj

Zatič

Smer

zategovanja

Smer

zategovanja