83

12

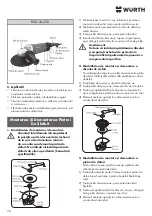

5. Prilagajanje postavitve glave

na kotni brusilki

Odstranite zatič iz svojega mesta pred uporabo.

Za uporabo v navedene zgornje primere zavrtite

glavo brusilnika za 90° namesto, da bi zavrteli

ročaj naprave. Nato odvijte štiri vijake, ki so na

glavi brusilnika. Glave ne odstranjujte popolnoma iz

ohišja ampak jo samo zavrtite v željeni položaj. Po

nastavitvi čvrsto privijte nazaj vijake.

6. Kako obrniti ročaj na kotni brusilki

20

2. Pressing angle

Do not press the whole surface of the grinding stone to

the grinding surface. It is recommended to use the disc

grinder by inclining it in 15-30 degrees as the picture to

do grinding work with circumference of the grinding

stone.

3. Grinding direction

When using a new grinding stone, be certain to grind

while pulling tool backwards (B direction) until the

grinding stone becomes rounded on its edge. Then, the

grinder can be moved to any direction.

This grinding stone (Grinding particle: A, Mesh: #36) is

best for heavy grinding in general steel materials. Also,

it can be used in wide range of other materials. For its

lower mesh, apply the grinding stone to the work

material lightly and grind steadily to create smooth

finishing surface that can be made by the grinding stone

with higher mesh.

4. Caution after use

Switch off to stop the rotation of the grinding stone, and

keep the disc grinder in safe place.

When you keep the disc grinder with the grinding stone

rotated in the place filled with dust and shavings, dust

and shavings can be gotten into the disc grinder.

The grinding stone can be cracked or

grooved by an impact. Please take care

not to impact on the disc grinder. If the

disc grinder is hit against something or

fallen down, you must check the

grinding stone and disc grinder.

5. How to rotate the head of the disc grinder

Remove the plug from plug socket before any operation.

For the above purpose, rotate the head of the disc

grinder in a 90-degree turn instead of rotating the

handle. And then, unscrew four screws and the head.

Do not remove the head from the main body wholly but

rotate to new position. After that, set four screws and

fasten them.

20

6. How to rotate the handle of the disc grinder

Disconnect the plug from the power

supply before making any maintenance.

1. Change of the grinding stone

Please change the grinding stone with new one when

outer diameter of the grinding stone in 180mm is worn

to

100mm

(For

the

grinding stone in 230mm is

130mm).

2. Screws

Make sure screws in each part are set tightly at regular

intervals. When screws are loose, fasten them tightly.

The loose screw causes the danger situation.

3. Carbon brush

Disposable carbon brush is used in the motor. The

heavily worn carbon brush causes the trouble of the

motor.

When the length of the carbon brush is reached at the

wear tolerance line, change it with new carbon brush.

Also, keep the carbon brush clean to be moved in the

brush holder freely.

Maintenance

Side handle

20

2. Pressing angle

Do not press the whole surface of the grinding stone to

the grinding surface. It is recommended to use the disc

grinder by inclining it in 15-30 degrees as the picture to

do grinding work with circumference of the grinding

stone.

3. Grinding direction

When using a new grinding stone, be certain to grind

while pulling tool backwards (B direction) until the

grinding stone becomes rounded on its edge. Then, the

grinder can be moved to any direction.

This grinding stone (Grinding particle: A, Mesh: #36) is

best for heavy grinding in general steel materials. Also,

it can be used in wide range of other materials. For its

lower mesh, apply the grinding stone to the work

material lightly and grind steadily to create smooth

finishing surface that can be made by the grinding stone

with higher mesh.

4. Caution after use

Switch off to stop the rotation of the grinding stone, and

keep the disc grinder in safe place.

When you keep the disc grinder with the grinding stone

rotated in the place filled with dust and shavings, dust

and shavings can be gotten into the disc grinder.

The grinding stone can be cracked or

grooved by an impact. Please take care

not to impact on the disc grinder. If the

disc grinder is hit against something or

fallen down, you must check the

grinding stone and disc grinder.

5. How to rotate the head of the disc grinder

Remove the plug from plug socket before any operation.

For the above purpose, rotate the head of the disc

grinder in a 90-degree turn instead of rotating the

handle. And then, unscrew four screws and the head.

Do not remove the head from the main body wholly but

rotate to new position. After that, set four screws and

fasten them.

20

6. How to rotate the handle of the disc grinder

Disconnect the plug from the power

supply before making any maintenance.

1. Change of the grinding stone

Please change the grinding stone with new one when

outer diameter of the grinding stone in 180mm is worn

to

100mm

(For

the

grinding stone in 230mm is

130mm).

2. Screws

Make sure screws in each part are set tightly at regular

intervals. When screws are loose, fasten them tightly.

The loose screw causes the danger situation.

3. Carbon brush

Disposable carbon brush is used in the motor. The

heavily worn carbon brush causes the trouble of the

motor.

When the length of the carbon brush is reached at the

wear tolerance line, change it with new carbon brush.

Also, keep the carbon brush clean to be moved in the

brush holder freely.

Maintenance

Side handle

Izklopite napravo iz električne

napeljave pred izvajanjem

vzdrževanja.

1. Menjava brusilne plošče

• Prosimo, da zamenjate obrabljeno brusilno ploščo, ko

je njen zunanji premer 100 mm (pri 180 mm ploščah)

in ko je premer 130 mm (pri 230 mm ploščah).

2. Vijaki

• Bodite pozorni, da so vsi vijaki na napravi dobro

pritrjeni. Če so vijaki zrahljani jih dobro privijte.

Zrahljani vijaki lahko privedejo do nevarnih poškodb.

3. Ogljikove (karbonske) krtačke

• Ogljikove krtačke so potrošni materjal, ki je

uporabljen v motorju. Nameščeno je samodejen

izklop napajanja naprave (avto-stop), ko so ogljikove

krtačke izrabljene. Ko se naprava noče prižgati

ali neha delovati, preverite obrabo krtačk in jih po

potrebi zamenjajte.

• Kupujte samo originalne rezervne dele. Ko

uporabljate rezervne dele, ki niso potrjeni

s strani proizvajalca, se ti lahko prehitro

obrabijo, naredijo poškodbo na napravi in

skrajšajo življenjsko dobo naprave.

•

Zamenjava krtačk:

Odstranite zadnji pokrov

naprave in zamenjajte krtačke na motorju.

9. Vzdrževanje

17

Check before Use

2. The extension cord

When the power source is located far from your

location, you may use the extension cord. However, you

should use the extension cord with proper length and

thickness not to prohibit the current. When you use too

long or thin extension cord, the voltage drop will be

higher. In result, the power of the motor will be

decreased. Please use the shortest extension cord

possible.

When the extension cord is damaged,

you must change or repair it

immediately.

3. The power source

You must use the tool in the power source specified in

the nameplate. When you use the tool for 110V in

220V/230V, the speed of the motor will be increased

abnormally. In result, the grinding stone and the tool

may be damaged.

When you use the tool for 110V in

220V/230V, the motor can be damaged

by a fire.

4. The switch

When you plug in the power source with

the tool switched on, you may be injured

seriously by sudden rotating of the tool.

Make sure the switch lever is returned to its original

position by pushing or pulling it.

5. The wheel guard

The wheel guard is a protective wall

preparing for the damage of the

grinding stone. You must install the

wheel guard.

You can set the desired angle of the wheel guard by

unfastening two small screws. Please use the tool after

adjusting the angle of the wheel guard for the work.

After adjustment, please fasten two small screws tightly.

6. Checking and installing the grinding stone

Be sure the grinding stone is in normal

condition and free from cracks or

damage. Make sure the grinding stone is

installed securely. To install the grinding

stone, see to the section installing and

removing grinding stone.

7. Mains Outlet

When inserting the plug, if a sound is heard or if it is a

taken out easily, you must repair it. Please contact

nearby electric shop.

When you use the mains outlet as it is, it causes the

accident by overheating.

8. Trial run

Always make a trial run before operation with grinding

stone pointed away from people to check the tool.

Before switching on the disc grinder, be

sure the rotating part of the disc grinder

is not contacted work material.

Accidental switching on with contacted

other objects may cause personal injury

by damaged grinding stone.

9. An explanation of any symbols or

pictograms marked on the tool relevant to

safe use

10. Product type

Nominal cross

section of

conductor

1.0 mm²

1.5 mm²

2.5 mm²

Nominal cross

section of

conductor

1.0 mm²

1.5 mm²

2.5 mm²

Max.

lenght

10 m

15 m

25 m

Max.

lenght

20 m

30 m

50 m

110-120 V

220-240 V

Trial run time

When replacing grinding stone

When using grinder initialy

3 minutes or more

1 minute or more

n

V

A

Hz

W

/min

~

rated speed

volts

amperes

hertz

watts

Handle

Only

plastic

Soft-

starter

Restart-

pro

Soft-starter

plastic

+

rubber

Lock-off

(2pole,

2 terminal)

Lock-on

(2pole,

2 terminal)

Lock-on

(1pole,

4 terminal)

Switch

Controller

Product

TYPE 1

TYPE

TYPE 2

TYPE 3

TYPE 4

TYPE 5

TYPE 6

TYPE 7

TYPE 8

revolutions or reciprocations per minute

alternating current

Class II construction

Disposal of Old Electrical &

Electronic Equipment

1. Connection to Power Supply

[110-120 V ]

[220-240 V ]

~

~

20

2. Pressing angle

Do not press the whole surface of the grinding stone to

the grinding surface. It is recommended to use the disc

grinder by inclining it in 15-30 degrees as the picture to

do grinding work with circumference of the grinding

stone.

3. Grinding direction

When using a new grinding stone, be certain to grind

while pulling tool backwards (B direction) until the

grinding stone becomes rounded on its edge. Then, the

grinder can be moved to any direction.

This grinding stone (Grinding particle: A, Mesh: #36) is

best for heavy grinding in general steel materials. Also,

it can be used in wide range of other materials. For its

lower mesh, apply the grinding stone to the work

material lightly and grind steadily to create smooth

finishing surface that can be made by the grinding stone

with higher mesh.

4. Caution after use

Switch off to stop the rotation of the grinding stone, and

keep the disc grinder in safe place.

When you keep the disc grinder with the grinding stone

rotated in the place filled with dust and shavings, dust

and shavings can be gotten into the disc grinder.

The grinding stone can be cracked or

grooved by an impact. Please take care

not to impact on the disc grinder. If the

disc grinder is hit against something or

fallen down, you must check the

grinding stone and disc grinder.

5. How to rotate the head of the disc grinder

Remove the plug from plug socket before any operation.

For the above purpose, rotate the head of the disc

grinder in a 90-degree turn instead of rotating the

handle. And then, unscrew four screws and the head.

Do not remove the head from the main body wholly but

rotate to new position. After that, set four screws and

fasten them.

20

6. How to rotate the handle of the disc grinder

Disconnect the plug from the power

supply before making any maintenance.

1. Change of the grinding stone

Please change the grinding stone with new one when

outer diameter of the grinding stone in 180mm is worn

to

100mm

(For

the

grinding stone in 230mm is

130mm).

2. Screws

Make sure screws in each part are set tightly at regular

intervals. When screws are loose, fasten them tightly.

The loose screw causes the danger situation.

3. Carbon brush

Disposable carbon brush is used in the motor. The

heavily worn carbon brush causes the trouble of the

motor.

When the length of the carbon brush is reached at the

wear tolerance line, change it with new carbon brush.

Also, keep the carbon brush clean to be moved in the

brush holder freely.

Maintenance

Side handle

20

2. Pressing angle

Do not press the whole surface of the grinding stone to

the grinding surface. It is recommended to use the disc

grinder by inclining it in 15-30 degrees as the picture to

do grinding work with circumference of the grinding

stone.

3. Grinding direction

When using a new grinding stone, be certain to grind

while pulling tool backwards (B direction) until the

grinding stone becomes rounded on its edge. Then, the

grinder can be moved to any direction.

This grinding stone (Grinding particle: A, Mesh: #36) is

best for heavy grinding in general steel materials. Also,

it can be used in wide range of other materials. For its

lower mesh, apply the grinding stone to the work

material lightly and grind steadily to create smooth

finishing surface that can be made by the grinding stone

with higher mesh.

4. Caution after use

Switch off to stop the rotation of the grinding stone, and

keep the disc grinder in safe place.

When you keep the disc grinder with the grinding stone

rotated in the place filled with dust and shavings, dust

and shavings can be gotten into the disc grinder.

The grinding stone can be cracked or

grooved by an impact. Please take care

not to impact on the disc grinder. If the

disc grinder is hit against something or

fallen down, you must check the

grinding stone and disc grinder.

5. How to rotate the head of the disc grinder

Remove the plug from plug socket before any operation.

For the above purpose, rotate the head of the disc

grinder in a 90-degree turn instead of rotating the

handle. And then, unscrew four screws and the head.

Do not remove the head from the main body wholly but

rotate to new position. After that, set four screws and

fasten them.

20

6. How to rotate the handle of the disc grinder

Disconnect the plug from the power

supply before making any maintenance.

1. Change of the grinding stone

Please change the grinding stone with new one when

outer diameter of the grinding stone in 180mm is worn

to

100mm

(For

the

grinding stone in 230mm is

130mm).

2. Screws

Make sure screws in each part are set tightly at regular

intervals. When screws are loose, fasten them tightly.

The loose screw causes the danger situation.

3. Carbon brush

Disposable carbon brush is used in the motor. The

heavily worn carbon brush causes the trouble of the

motor.

When the length of the carbon brush is reached at the

wear tolerance line, change it with new carbon brush.

Also, keep the carbon brush clean to be moved in the

brush holder freely.

Maintenance

Side handle

13

repair the tool for themselves. Contact nearby A/S

center (agencies) for solution.

7. X attachment cord

If the supply cord of this power tool is damaged, it must

be replaced by a specially prepared cord available

through the service organization.

We declares that these products meet the standards

EN 60745-1, EN 60745-2-3, EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3 in compliance with the

directives 2006/42/EC, 2004/108/EC, 2011/65/EU.

EC Declaration of conformity

D. Assimosis

M. Weiss

General Manager

Executive Vice President

Technical documentation at:

Würth Hellas SA

23rd

Km

Athens-Lamia

National

Road,

145

68

Krioneri

Attica,

Greece

6. Abnormal operation

It is very dangerous for customers to troubieshoot or

repair the tool for themselves. Contact nearby A/S

center (agencies) for solution.

7. X attachment cord

If the supply cord of this power tool is damaged, it must

be replaced by a specially prepared cord available

through the service organization.

We declares that these products meet the standards

EN 60745-1, EN 60745-2-3, EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3 in compliance with the

directives 2006/42/EC, 2004/108/EC, 2011/65/EU.

EC Declaration of conformity

D. Assimosis

M. Weiss

General Manager

Executive Vice President

Technical documentation at:

Würth Hellas SA

23rd

Km

Athens-Lamia

National

Road,

145

68

Krioneri

Attica,

Greece

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and

other European countries with separate collection systems)

This symbol on the product or on its packaging indicates that this product shall

not be treated as household waste. Instead it shall be handed over to the

applicable collection point for the recycling of electrical and electronic

equipment. By ensuring this product is disposed of correctly, you will help

prevent potential negative consequences for the environment and human

health, which could otherwise be caused by inappropriate waste handling of

this product. The recycling of materials will help to conserve natural resources.

For more detailed information about recycling of this product, please contact

your local city office, your household waste disposal service or the shop

where you purchased the product.

* We may apply the auto-stop carbon brush for

improvement in quality without previous notice. Auto-

stop will interrupt current automatically for wear of the

carbon brush. When the disc grinder is stopped for the

built-in auto-stop, check the carbon brush and change it.

How to change

: Remove the brush cap with the

minus driver to take off the carbon brush.

You must purchase the genuine parts in

A/S centers authorized by Würth

company for change. When you use the

carbon brush other than the genuine

parts, the commutator may be worn

rapidly. In result, the life of the tool can

be shortened.

4. Motor

The winding and commutator in the motor are the core

of the disc grinder.

Do not scratch the surface of the winding and

commutator in the motor, and do not apply oil or water

on it.

Dust in the motor causes the trouble of

the motor. After using the disc grinder

for 50hours, let the compressed air in the

ventilation slots in the handle side by

rotating the disc grinder in no-load

revolution to eliminate dust from the

motor.

5. Keep after operation

You must keep the tool out of reach of children in dry

place.

6. Abnormal operation

It is very dangerous for customers to troubieshoot or

repair the tool for themselves. Contact nearby A/S

center (agencies) for solution.

7. X attachment cord

If the supply cord of this power tool is damaged, it must

be replaced by a specially prepared cord available

through the service organization.

Zagotavljamo, da se izdelki skladajo z naslednjimi

standardi: EN 60745-1, EN 60745-2-3, EN 55014-1, EN

55014-2, EN 61000-3-2, EN 61000-3-3

v skladu z direktivami 2006/42/EC, 2014/30/EU,

2011/65/EU.

Tehnična dokumentacija je na voljo pri:

Würth Hellas SA, 23rd Km Athens-Lamia National Road,

14568 Krioneri Attica, Grčija

D. Assimosis

M. Weiss

Generalni direktor

Izvršni podpredsednik

V skladu z Direktivo 2012/19/EU

Evropskega Parlamenta in Sveta o odpadni

električni in elektronski opremi (OEEO)

in njeni uresničitvi v nacionalnem pravu

se morajo električna orodja, ki niso več v

uporabi, ločeno zbirati ter okolju prijazno

reciklirati.

4. Motor

• Navitje in komutator motorja sta jedro brusilke.

• Ne krtačite ali brusite navitja in komutatorja motorja,

ne nanašajte olja ali vode nanju.

Prah v motorju povzro

č

a napake pri

delovanju. Pri stalnu uporabi brusilke

pogosto izpihajte ventilacijski del motorja

skozi re

ž

e s stisnjenim zrakom.

5. Varno shranjevanje naprave

Brusilko shranjujte na varnem in suhem prostoru.

Preprečite dostop otrokom.

6. Servis

Zelo nevarno je, če se sami lotite odpravljanja napak

ali servisiranja naprave. To naj opravi pooblaščen

serviser, kontaktirajte prodajalca naprave.

7. Priklju

č

ni kabel

• Če je napajalni kabel poškodovan, morate poskrbeti

za zamenjavo s primernim napajalnim kablom.

• To naj opravi pooblaščen serviser, kontaktirajte

prodajalca naprave.

10. CE izjava o skladnosti