Commissioning

5

Translation of the original operation manual

27

27

•303_208176_1004_en•ski

WARNING!

In case the equipment does

not

switch itself off, turn back the pressure at the air main-

tenance unit to 0 bar and DO NOT proceed further with the commissioning! First check

the 3/2-way valve for emergency shut-off of the air supply. Exchange defected parts if

necessary and start commissioning procedure all over again.

➤

Set a low inbound air pressure on the air regulators (pos. 10.1) of the feed pumps. The

pumps should cycle slowly (approx. 1 - 2 bar).

➤

Flush thoroughly through the return hoses (pos. 9) and allow the thinner to flow out

into an open stand-by container until clean thinner appears.

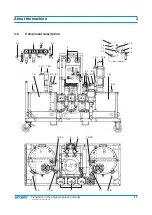

2. Step: Cleaning from mixer to the spray gun*

Settings on the mixer (Spray)

➤

Turn lever on the external mixer:

➤

SPRAY (pos. 13.2) to “OPEN”.

➤

FLUSH (pos. 13.3 A / B) to “CLOSED”.

➤

CIRCULATE (pos. 13.1) to “CLOSED”.

➤

Unlock the spray gun*.

➤

Spray into an open container the rest contaminated thinner which is in the system

until clean thinner appears. Lock the spray gun* when finished.

➤

Turn back the air regulator completely.

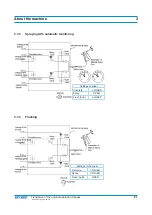

Settings on the mixer (Circulate)

➤

Turn lever on the external mixer:

➤

SPRAY (pos. 13.1) to “CLOSED”.

➤

FLUSH (pos. 13.3 A / B) to “CLOSED”.

➤

CIRCULATE (pos. 13.2) to “OPEN”.

➤

Remove the return hoses from the filling containers and secure them each in a sepa-

rate open container.

➤

Set a low pressure on the regulator (pos. 2.2) of the main pump and circulate as long as

both material containers are empty.

If the viscosity of the material allows for draining through the drain valve, place empty

containers under the drain valves (pos.7.1) and open the valves to collect the remaining

material in the containers.

Close the drain valves when the containers are empty and then clean the material

containers.

If draining is not possible, spray the remaining material into empty containers for

contaminated material and then clean the material containers.