4

Assembly and Setting up

22

Translation of the original operation manual

•303_208176_1004_en•ski

4

Assembly and Setting up

Having processing material ready

All materials to be sprayed should be marked with information on viscosity, processing

temperatures, mixing proportions etc. If this is not the case, please request this data from

the relevant material manufacturer.

offers a broad selection of special attachments for the optimal preparation of

spraying materials, e.g.:

➤

agitators in various sizes

➤

material pre-warming containers in various sizes

➤

fluid heaters

➤

equipment for hose heating

➤

equipment for heating the bottom of the material container

➤

heating band for material container

Setting up and preparation

The machine is to be set up securely on a level and solid surface. All operating elements

must be easily accessible. In order that the necessary volume of air is guaranteed the

compressor capacity must comply with the amount of air needed by the machine and the

diameter of the air supply hoses must correspond to the joints.

High Pressure spray machines and systems can be installed inside and outside of spray

cabins and spray rooms. To avoid contamination, outside installations are preferable.

To avoid damage during transportation, some external components of the machine may

be unscrewed and packed in a separate box. In this case, please add these parts in ac-

cordance with the diagram of the machine enclosed in the user‘s handbook.

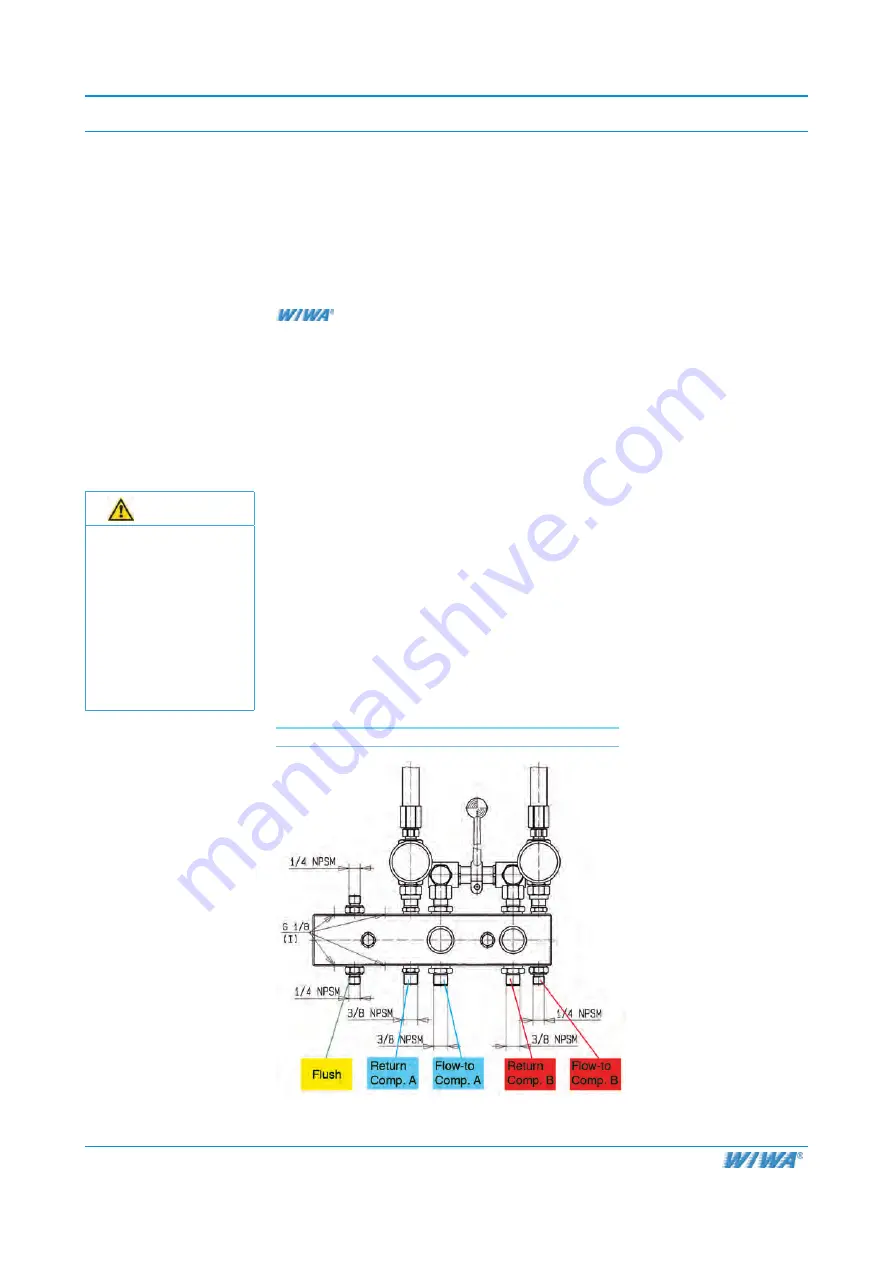

Connect the material hoses on the intermediate piece

Picture 4.1

WARNING!

Due to high friction

while spraying, elec-

trostatic charge on the

spraying gun can be the

result.

In order to prevent static

charging, the airless sys-

tem must be grounded

by attaching the ground

cable to a conductive

object.