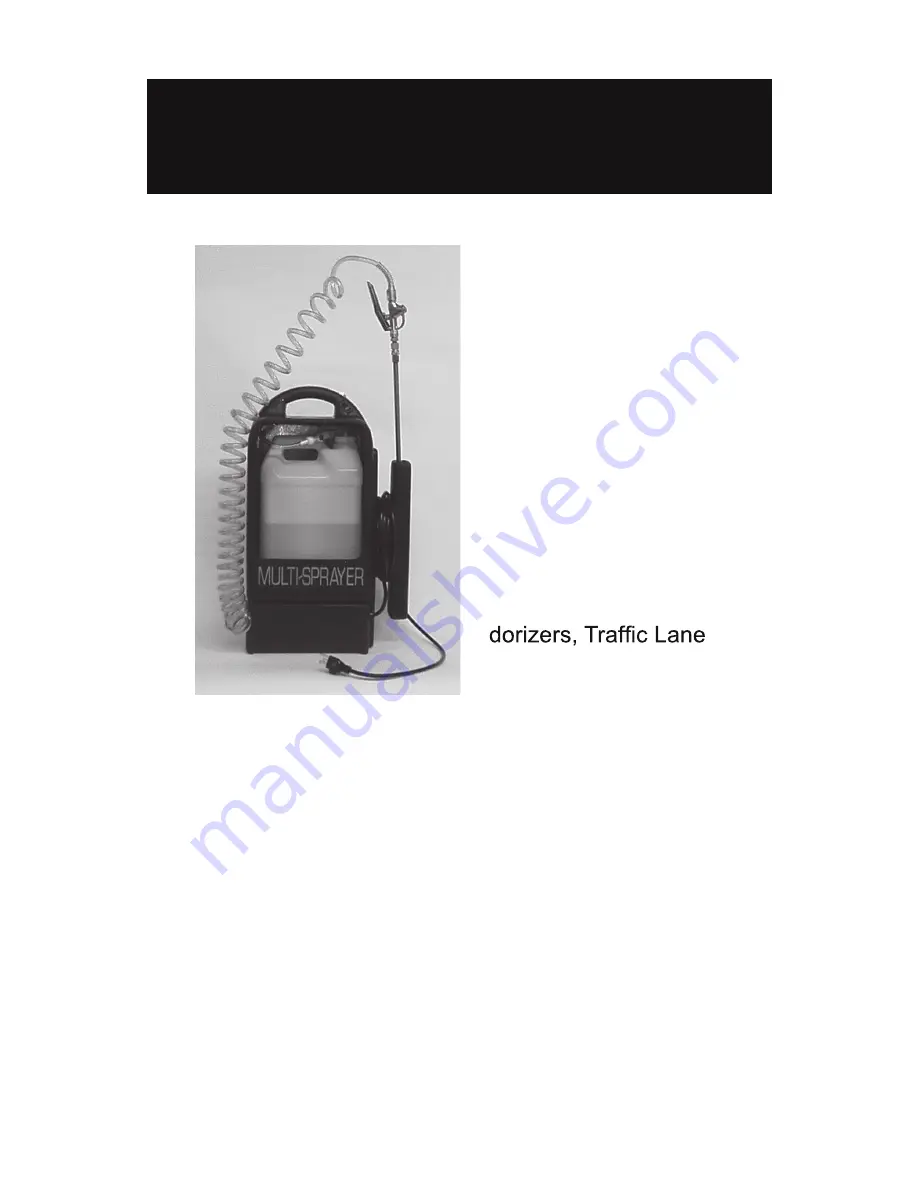

Multi-Sprayer

™

•Carpet & Upholstery

Pre & After Sprays

•Ceiling Cleaning

•Janitorial Sprays

•Carpet Restoration

Applications

Ideal For:

Disinfectants, Deo

-

Cleaners, Spotting

Agents, Insecticides,

Garden Agents & Fer

-

tilizers, Cleans Ducts,

Ovens & Siding

Also Sprays:

OWNERS MANUAL

M1

M2

For Parts & Service Call:

www

.multi-sprayer.com

(Now also available in cordless recha

rgeable models)

APPROXIMATE RATE OF SPRAY FROM T-JETS & V-JETS

USING 50 PSI PUMP:

TI

P

SIZE

XX050

XX01

XX015

XX02

XX03

XX04

XX05

XX06

XX08

XX10

GAL

per MIN

.055

.11

.16

.22

.33

.44

.55

.66

.88

1.10

XX - Degree of Arc of

Spray. Available from 0

to 110 Degrees.

TROUBLE SHOOTING

Motor operates, but no spray:

• If you have M2 model, see “Getting Started” instructions

on Page 3 and on back of sprayer

• Restricted intake or discharge line. Clogged suction

strainer, kinked suction or spray hose, clogged spray tip,

broken or clogged trigger

• Air leak in suction hose

• Broken or worn pump parts; valve chamber, or diaphragm

Motor fails to run:

• Switch defective or loose wiring connection

• Defective motor

• Frozen cam bearing

• Partially clogged lines, strainers, tip or trigger

• Worn pump cam bearing (also excessive noise)

• Broken or worn pump parts; valve chamber or diaphragm

Leaking:

• Hole in hose, cracked pump housing, loose or broken

hose barb at pump inlet or outlet, loose or broken

hose clamp at pump inlet or outlet

Multi-Sprayer Systems, Inc.

4810 Park Glen Road, St. Louis Park, MN 55416

www.multi-sprayer.com | [email protected]

800-669-2469 | 952-767-3063

Page 8

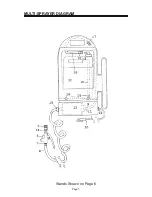

MULTI-SPR

AYER DIAGRAM

Wands Shown on Page 6

Page 5

MULTI-SPR

AYER

PARTS

KEY

*5

6

**

7

8

9

11

12

*14

15

16

17

18

19

20

21

22

23

24

25

PA

R

T#

BS

T

-1YSS

6590

6590-VIKIT

125HBL-4-4

FW

-10

SNP-2

N4MEB6

AQ115

216P-4-2

1

1375

ARD

16001

1E

UR33

13862-50

18110

SR7W

-2

2G

F17004LG

M22004LG

UR12.5

AQ115

LHA

VHA

UHA

DESCRIPTION

SSFemale Coupler, 1/8”

Brass/

V

iton

T

rigger

T

rigger

V

alve Repair Kit

Brass Hose Barb, 1/4” x 1/4”

Urethane Coiled Spray Hose 10” 1/4 ID

Hose Clamp, Nylon

Elbo

w

, Nylon

1

15V Motor & Pump

Brass Reducing Nipple, 1/4” / 1/8”

Rubber Hose Grommet

Base Plate Retainer Button

Electric On/O

f

f Switch

Urethane Suction Hose, 33”, 1/4 ID

Suction Hose Strainer, 50 mesh

Power Cord, 20 Feet

Power Cord Strain Relief

2 Gallon Solution Container

Female Jug QC

Male Jug QC, Cap and 90 Degree Barb

Urethane Dip

T

ube, 12.5” 1/4 ID

1

15

V

olt Pump Parts

Lower Head Assembl

y,

T

riangular dia

-

phragm/CAM

V

alve Assembl

y, 3 Inlet and 2 Outlet

V

alves

Black Poly Pump Head

*Parts #5 and #14 on M2 Model Only

If pump leaks from small triangle on black pump head, replace

#UHA. If pump runs but does not pump, replace VH

A

and LHA.

Page 4

m1-11-17.indd 1

10/1/2012 11:05:12 AM

Multi-Sprayer

™

•Carpet & Upholstery

Pre & After Sprays

•Ceiling Cleaning

•Janitorial Sprays

•Carpet Restoration

Applications

Ideal For:

Disinfectants, Deo

-

Cleaners, Spotting

Agents, Insecticides,

Garden Agents & Fer

-

tilizers, Cleans Ducts,

Ovens & Siding

Also Sprays:

OWNERS MANUAL

M1

M2

For Parts & Service Call:

www

.multi-sprayer.com

(Now also available in cordless recha

rgeable models)

APPROXIMATE RATE OF SPRAY FROM T-JETS & V-JETS

USING 50 PSI PUMP:

TI

P

SIZE

XX050

XX01

XX015

XX02

XX03

XX04

XX05

XX06

XX08

XX10

GAL

per MIN

.055

.11

.16

.22

.33

.44

.55

.66

.88

1.10

XX - Degree of Arc of

Spray. Available from 0

to 110 Degrees.

TROUBLE SHOOTING

Motor operates, but no spray:

•If you have M2 model, see “Getting Started” instructions

on Page 3 and on back of sprayer

•Restricted intake or discharge line. Clogged suction

strainer, kinked suction or spray hose, clogged spray tip,

broken or clogged trigger

•Air leak in suction hose

•Broken or worn pump parts; valve chamber, or diaphragm

Motor fails to run:

•Switch defective or loose wiring connection

•Defective motor

•Frozen cam bearing

•Partially clogged lines, strainers, tip or trigger

•Worn pump cam bearing (also excessive noise)

•Broken or worn pump parts; valve chamber or diaphragm

Leaking:

•Hole in hose, cracked pump housing, loose or broken

hose barb at pump inlet or outlet, loose or broken

hose clamp at pump inlet or outlet

Multi-Sprayer Systems, Inc.

3515 Hennepin

A

venue South

Minneapolis, MN 55408

800-669-2469 | 612-825-5354

Page 8

MULTI-SPR

AYER DIAGRAM

Wands Shown on Page 6

Page 5

MULTI-SPR

AYER

PARTS

KEY

*5

6

**

7

8

11

12

*14

15

16

17

18

19

20

21

22

23

24

25

PA

R

T#

BS

T

-1YSS

6590

6590-VIKIT

H14-2MUSBR

FW

-10

N4MEB6

AQ115

216P-4-2

1

1375

ARD

16001

1E

UR33

13862-50

18110

SR7W

-2

2G

F17004LG

M22004LG

UR12.5

AQ115

LHA

VHA

UHA

DESCRIPTION

SSFemale Coupler, 1/8”

Brass/

V

iton

T

rigger

T

rigger

V

alve Repair Kit

Compression and Strain Relief

Urethane Coiled Spray Hose 10” 1/4 ID

Elbo

w

, Nylon

1

15V Motor & Pump

Brass Reducing Nipple, 1/4” / 1/8”

Rubber Hose Grommet

Base Plate Retainer Button

Electric On/O

f

f Switch

Urethane Suction Hose, 33”, 1/4 ID

Suction Hose Strainer, 50 mesh

Power Cord, 20 Feet

Power Cord Strain Relief

2 Gallon Solution Container

Female Jug QC

Male Jug QC, Cap and 90 Degree Barb

Urethane Dip

T

ube, 12.5” 1/4 ID

**

M22

Male QC

1

15

V

olt Pump Parts

Lower Head Assembl

y,

T

riangular dia

-

phragm/CAM

V

alve Assembl

y, 3 Inlet and 2 Outlet

V

alves

Black Poly Pump Head

*Parts #5 and #14 on M2 Model Only

If pump leaks from small triangle on black pump head, replace

#UHA. If pump runs but does not pump, replace VH

A

and LHA.

Page 4

m1-11-17.indd 1

10/1/2012 11:05:12 AM

**

Cap & 90

Cap and 90 degree panel mount

• Male and/or female QC on jug failure