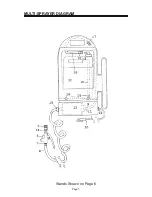

TO REMOVE PUMP

A. Remove nylon tabs by tapping out from

inside of solution container compartment

B. Remove bottom plate to access pump.

Page 7

INTRODUCTION

The Multi-Sprayer replaces pump-up sprayers.

The Multi-Sprayer is a tough, compact and versatile electric

sprayer, equipped with a

SOLVENT COMPATIBLE VITON

PUMP.

It was designed to be easily transported to the job

taking up limited space. On the job, its 20 foot electric cord

and 10 foot spray hose allow you to cover a large area from

each electric receptical.

TWO MODELS, THE M1 AND M2

Common features of the two models are:

•

Tough Polyethylene Case

•2 Gallon Quick Change Container Capability

•

115 Volt, 50 psi Pump (230 Volt Available)

•20 Foot Electric Cord & 10 Foot Spray Hose

•Pump is Solvent Compatible,

Viton Seals

•Spray

Trigger Has V

iton Seal; also QC

•One

Year Warranty Parts and Labor

M1 FE

ATURES

•2 Foot

Wand with 8004 or 8005 V-jet Nozzle

•

Weight 11 Pounds Empty

M2 FE

ATURES

•2 Foot

Wand with 8004 T-Jet with a Check Valve/

Strainer

•Extra 50015

T-Jet Tip for Upholstery with a Check

Valve/Strainer

•

Weight 12 Pounds Empty

SAFETY PROCEDURES

•RISK OF EXPLOSION--DO NO

T SPRAY COM-

BUSTIBLE FLUIDS

•PLUG IN

TO 115-120 VOLT 50/60 CYCLE

GROUNDED 3-PRONG RECEP

TACLE

Page 2

M1 W

AND

KEY

1

2

3

PAR

T#

H1/8DT-8004

SS20

AB110CA

DESCRIPTION

Female

Thread Brass

V-Jet Nozzle

Threaded S.S. W

and T

ube

Brass Hex Nipple, 1/4 Male/1/8 Female

M2 W

ANDS (W

AC & W

ACS)

KEY

1A

2

2A

24

3

25

2

1B

24

2A

25

WAC

TPU8004SS

CP1325

CP1335

419

3-A

-10

-50

SS

SS2

0

BST

-N

1SS

WACS

CP1325

TPU50015

419

3-A

-20

-50

SS

CP1336

BST-N1

Complete Carpet W

and

SS T

-Jet Nozzle

Brass Nozzle Cap

Brass Male Body

Strainer W/Check Valve (inside 2A)

Stainless Steel W

and T

ube

SS Male Coupler

Complete Upholstry W

and

Brass Nozzle Cap

Brass T

-Jet Nozzle

Strainer W/Check Valve (inside 2A)

Brass Male Body

BR Male Coupler

8004W

AND

Complete M1 W

and, Parts 1, 2, 3

Carpet W

and -W

AC

Upholstery W

and -W

ACS

(exploded)

Page 6

1

2

3

2 1B 24 2

A

25

1A 2 2

A 3 25

GETTING S

TARTED

Slant your 2 gallon container of solution into the Multi-

out, connect the male/female cap quick connect system.

Then push the container into the Multi-Sprayer.

To remove

container, push the silver tab on the female quick connect tip

out of container and remove.

Plug in, turn on switch and squeeze trigger to spray.

IF YOU H

AVE MODE

L M2...

1. Remove the 2 foot carpet wand or the upholstery tip at the

quick connect.

2. Squeeze the trigger, allowing the liquid to advance to near

the trigger.

3. Re-connect the 2 foot carpet wand or upholstery tip and

starting, but stop drips after spraying.

MAINTENANCE

At the end of the work period a mild detergent solution, fol-

lowed by fresh wate

r, should be sprayed to clean the pump

and hose. When switching between water based and solvent

case cleans easily with a mild detergent and retains its luster

with application of a plastic/vinyl product.

Your Multi-Sprayer carries a one year parts and labor war

-

ranty.

The date of manufacture is stamped on the serial

plate. Keep your receipt for exact date of ownership for

warranty purposes.

FREEZING CAN DAMAGE

the Multi-

Sprayer and is not covered by the warranty. Consult the

Chemical Guide available from your distributor or manufac

-

turer for chemical compatibility. Chemical damage to the

pump is not covered by the warranty.

GETTING S

TARTED

Page 3

m1-11-17.indd 2

10/1/2012 11:05:12 AM

TO REMOVE PUMP

A. Remove nylon tabs by tapping out from

inside of solution container compartment

B. Remove bottom plate to access pump.

Page 7

INTRODUCTION

The Multi-Sprayer replaces pump-up sprayers.

The Multi-Sprayer is a tough, compact and versatile electric

sprayer, equipped with a

SOLVENT COMPATIBLE VITON

PUMP.

It was designed to be easily transported to the job

taking up limited space. On the job, its 20 foot electric cord

and 10 foot spray hose allow you to cover a large area from

each electric receptical.

TWO MODELS, THE M1 AND M2

Common features of the two models are:

•

Tough Polyethylene Case

•2 Gallon Quick Change Container Capability

•

115 Volt, 50 psi Pump (230 Volt Available)

•20 Foot Electric Cord & 10 Foot Spray Hose

•Pump is Solvent Compatible,

Viton Seals

•Spray

Trigger Has V

iton Seal; also QC

•One

Year Warranty Parts and Labor

M1 FE

ATURES

•2 Foot

Wand with 8004 V-jet Nozzle

•

Weight 11 Pounds Empty

M2 FE

ATURES

•2 Foot

Wand with 8004 T-Jet with a Check Valve/

Strainer

•Extra 50015

T-Jet Tip for Upholstery with a Check

Valve/Strainer

•

Weight 12 Pounds Empty

SAFETY PROCEDURES

•RISK OF EXPLOSION--DO NO

T SPRAY COM-

BUSTIBLE FLUIDS

•PLUG IN

TO 115-120 VOLT 50/60 CYCLE

GROUNDED 3-PRONG RECEP

TACLE

Page 2

M1 W

AND

KEY

1

2

3

PAR

T#

H1/8DT-8004

SS20

AB110CA

DESCRIPTION

Female

Thread Brass

V-Jet Nozzle

Threaded S.S. W

and T

ube

Brass Hex Nipple, 1/4 Male/1/8 Female

M2 W

ANDS (W

AC & W

ACS)

KEY

1A

2

2A

24

3

25

2

1B

24

2A

25

WAC

TPU8004SS

CP1325

CP1335

419

3-A

-10

-50

SS

SS2

0

BST

-N

1SS

WACS

CP1325

TPU50015

419

3-A

-20

-50

SS

CP1336

BST-N1

Complete Carpet W

and

SS T

-Jet Nozzle

Brass Nozzle Cap

Brass Male Body

Strainer W/Check Valve (inside 2A)

Stainless Steel W

and T

ube

SS Male Coupler

Complete Upholstry W

and

Brass Nozzle Cap

Brass T

-Jet Nozzle

Strainer W/Check Valve (inside 2A)

Brass Male Body

BR Male Coupler

8004W

AND

Complete M1 W

and, Parts 1, 2, 3

Carpet W

and -W

AC

Upholstery W

and -W

ACS

(exploded)

Page 6

1

2

3

2 1B 24 2

A

25

1A 2 2

A 3 25

GETTING S

TARTED

Slant your 2 gallon container of solution into the Multi-

out, connect the male/female cap quick connect system.

Then push the container into the Multi-Sprayer.

To remove

container, push the silver tab on the female quick connect tip

out of container and remove.

Plug in, turn on switch and squeeze trigger to spray.

IF YOU H

AVE MODE

L M2...

1. Remove the 2 foot carpet wand or the upholstery tip at the

quick connect.

2. Squeeze the trigger, allowing the liquid to advance to near

the trigger.

3. Re-connect the 2 foot carpet wand or upholstery tip and

starting, but stop drips after spraying.

MAINTENANCE

At the end of the work period a mild detergent solution, fol-

lowed by fresh wate

r, should be sprayed to clean the pump

and hose. When switching between water based and solvent

case cleans easily with a mild detergent and retains its luster

with application of a plastic/vinyl product.

Your Multi-Sprayer carries a one year parts and labor war

-

ranty.

The date of manufacture is stamped on the serial

plate. Keep your receipt for exact date of ownership for

warranty purposes.

FREEZING CAN DAMAGE

the Multi-

Sprayer and is not covered by the warranty. Consult the

Chemical Guide available from your distributor or manufac

-

turer for chemical compatibility. Chemical damage to the

pump is not covered by the warranty.

GETTING S

TARTED

Page 3

m1-11-17.indd 2

10/1/2012 11:05:12 AM