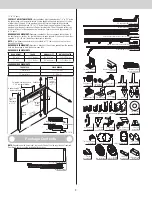

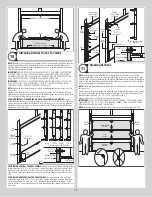

WARNING

FAILURE TO ASSEMBLE AND ATTACH REAR BACK HANGS PROPERLY

ACCORDING TO THE ABOVE INSTRUCTIONS MAY RESULT IN DOOR

FALLING WHEN RAISED, CAUSING SEVERE OR FATAL INJURY.

NOTE:

Perforated angle must be attached to sound framing members and

nails should not

be used

.

90°

(3) 5/16”

Bolts and nuts

(3) 5/16” Bolts and

(3) 5/16” nuts

Perforated

angle

5/16” Hex nut

5/16”-18 x 1-1/4”

Hex bolt

Perforated angle bolted

using (2) 5/16” x 1-5/8”

hex head lag screws to

ceiling member and

parallel to door

Horizontal track

NOTE:

Repeat the same

process for right hand side.

Horizontal tracks

Door edges

3/4” To 7/8”

3/4” To 7/8”

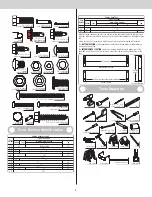

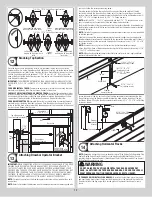

Attaching Front Cable Lift Sheaves

17

IF YOU HAVE 3” FRONT CABLE LIFT SHEAVE AND A 12” RADIUS HORIZONTAL TRACK:

Starting on the left hand side and using (1) 3/8” - 16 hex nut, secure the front cable lift

sheave to the 13/32” hole near the top of the flag angle, as shown.

IF YOU HAVE 3” OR 4” FRONT CABLE LIFT SHEAVE AND A 15” RADIUS HORIZONTAL

TRACK:

Starting on the left hand side and using (1) 3/8” - 16 hex nut, secure the front cable

lift sheave to the first 13/32” hole in the horizontal angle, as shown.

Repeat the same process for the right hand side.

Horizontal track angle

Horizontal track radius

Flag angle

3/8”-16

Hex nut

Horizontal

track angle

12” Radius horizontal

track with 3” front cable

lift sheave hole location

Horizontal track

15” Radius horizontal track

with 3” or 4” front cable lift

sheave hole location

or

12” Radius horizontal track

with 4” front cable lift

sheave hole location

3” or 4”

Front cable

lift sheave

Front cable lift sheave

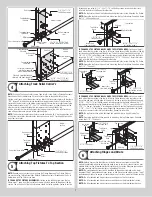

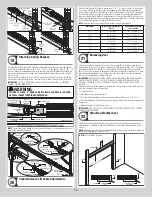

Attaching Extension Springs

18

Remove the locking pliers from the vertical tracks.

WARNING

WITH ASSISTANCE, RAISE THE DOOR SLOWLY INTO THE OPEN POSITION

MAKING SURE THE DOOR TRAVELS SMOOTHLY THROUGH THE TRACKS.

CLAMP LOCKING PLIERS TO THE BACK LEG OF BOTH HORIZONTAL

TRACKS, BELOW THE BOTTOM TRACK ROLLERS TO KEEP THE DOOR

FROM LOWERING.

Locking

pliers

NOTE:

This illustration shows the outside of the door

in the open position.

Bottom

section

Track

roller

WARNING

FAILURE TO INSTALL SPRING RESTRAINT CABLES CAN RESULT IN

SEVERE OR FATAL INJURY IN CASE OF SPRING BREAKAGE.

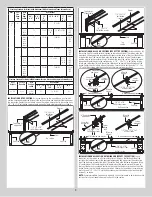

Position (1) 5/16” - 18 x 3-3/4” eye bolt and (1) 5/16” - 18 hex nut into the rear back hang,

6” to 8” above the horizontal track, as shown. Feed the spring safety cable through the rear

back hang and tie the special knot around the “room side” of the 3 hole clip, as shown.

Secure the eye bolt and 3 hole clip to the rear back hang using (1) 5/16” - 18 hex nut. Hook

one end of the extension spring onto the eye bolt. Feed the spring safety cable through the

rear extension spring loop and center of the extension spring then front spring loop, pull the

spring safety cable taut and tie the special knot around the “jamb side” of the 3 hole clip.

Attach the “jamb side” 3 hole clip to the jamb near the flag angle using (1) 5/16” x 1-5/8” lag

bolt. Repeat the same process for the other side.

IMPORTANT:

SPRING RESTRAINT CABLES MUST BE TAUT AND EQUALIZED.

5/16”-18 x 3-3/4”

Eye bolt

Horizontal

track

Extension

spring

Back

view

Front view

Spring restraint

cable

Spring

restraint cable

Loop

5/16” x 1-5/8”

Lag bolt

3 Hole

clip

Special

knot

3 Hole

clip

Rear

back

hang

Extension

spring

5/16”-18 x 3-3/4”

Eye bolt

Extension

spring

Spring

restraint

cable

14