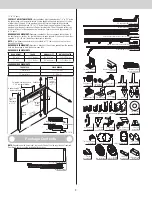

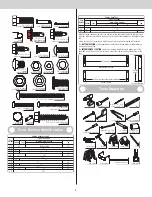

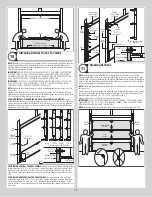

3/8”-16

Hex nut

3/8”-16 x

3/4” Truss

head bolt

Quick

Install

tab

Key

slot

Quick

Install

tab in

place

Level

Horizontal track angle

Flag

angle

upper

slot

Flag

angle

Horizontal

track

FOR OTHER FLAG ANGLES:

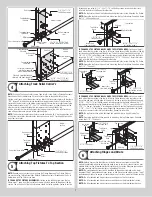

To install horizontal track, place the curved end over the top

track roller of the top section. Align the bottom of the horizontal track with the top of the verti-

cal track. Tighten the horizontal track to the flag angle with (2) 1/4” - 20 x 9/16” track bolts

and (2) 1/4” - 20 flange hex nuts.

3/8”-16

Hex nut

Horizontal

track angle

3/8”-16 x

3/4” Truss

head bolt

1/4”-20 x

9/16”

Track bolts

1/4”-20

Flange hex

nuts

Horizontal

track

Flag angle

upper slot

Level

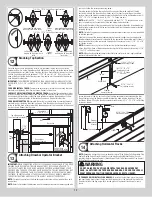

IF YOU HAVE ANGLE MOUNT:

To install horizontal track, place the curved end over the

top track roller of the top section. Align the bottom of the horizontal track with the top of the

vertical track. Tighten the horizontal track to the angle mount with (2) 1/4” - 20 x 9/16” track

bolts and (2) 1/4” - 20 flange hex nuts.

3/8”-16

Hex nut

Angle

mount

3/8”-16 x

3/4” Truss

head bolt

1/4”-20 x

9/16”

Track bolts

1/4”-20

Flange

hex nuts

Horizontal

track

Upper slot

Level

Vertical

track

Horizontal

track angle

Next level the horizontal track assembly and bolt the horizontal track angle to the first

encountered slot in the flag angle / angle mount using (1) 3/8” - 16 x 3/4” truss head bolt

and (1) 3/8” - 16 hex nut. Repeat for other side. Remove nail that was temporally holding the

top section in position.

IMPORTANT:

FAILURE TO REMOVE NAIL BEFORE ATTEMPTING TO RAISE DOOR COULD

CAUSE PERMANENT DAMAGE TO TOP SECTION.

Horizontal

track

Level

Level

Horizontal

track angle

Horizontal

track angle

Horizontal

track

Adjusting Top Fixtures

15

NOTE:

Depending on your door, you may have Top Fixture Bases and Top Fixture Slides or

you may have Top Fixture Assemblies. Refer to Package Contents / Breakdown of Parts, to

determine which Top Fixtures you have.

With horizontal tracks installed, you can now adjust the top fixtures. Vertically align the top

section of the door with the lower sections. Once aligned, position the top fixture slide, out

against the horizontal track. Maintaining the slide’s position, tighten the (2) 1/4” - 20 flange

hex nuts or the (1) 5/16” - 18 hex nut to secure the top fixture slide to the top fixture base.

Repeat for other side.

Top fixture slide

Tighten the (2)

1/4”- 20 flange

hex nuts

Horizontal

track

Track roller

Top section

Intermediate

section

Top

section

Top

section

Top fixture

slide

Horizontal

track

Track roller

Top

section

Intermediate

section

Top

section

Top

section

Tighten the

5/16”-18

hex nut

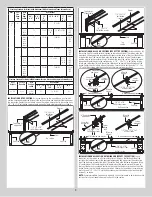

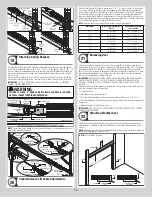

COUNTERBALANCE

INSTALLATION INSTRUCTIONS

Attaching Rear Back Hangs

16

Raise the door until the top section and half of the next section are in the horizontal track

radius. Do not raise door any further since rear of horizontal tracks are not yet supported.

WARNING

RAISING DOOR INTO THE LOOSE HORIZONTAL TRACKS CAN RESULT IN

DOOR FALLING AND CAUSE SEVERE OR FATAL INJURY.

Clamp a pair of locking pliers onto the vertical tracks just above the second track roller on

one side, and just below the second track roller on the other side. This will prevent the door

from raising or lowering while installing the rear back hangs.

Using the chart below, select the appropriate perforated angle (may not be supplied). Fabri-

cate and install rear back hangs, as shown.

NOTE:

If an opener is installed, position horizontal tracks one hole above level when securing

them to the rear back hangs.

Perforated Angle Gauge Weight Limitations For Extension Springs:

Perforated Angle Gauge

Door Balance Weight

2” x 2” x 12 Gauge

Less Than 400 lbs.

1-1/4” x 1-1/4” x 13 Gauge

Less Than 175 lbs.

WARNING

MAKE SURE BACK HANGS ARE BRACED SUFFICIENTLY TO RESIST ANY

MOTION DURING SPRING APPLICATION AND DOOR TRAVEL. IF BACK

HANGS PIVOT OR DEFLECT, ADD REINFORCEMENT UNTIL THEY REMAIN

FIRM AND STATIONARY. ANY BACK HANG THAT HAS BENT MUST BE

REPLACED.

WARNING

KEEP HORIZONTAL TRACKS PARALLEL AND WITHIN 3/4” TO 7/8” FROM

DOOR EDGE, OTHERWISE DOOR COULD FALL, RESULTING IN SEVERE OR

FATAL INJURY.

IMPORTANT:

DO NOT SUPPORT THE WEIGHT OF THE DOOR ON ANY PART OF THE REAR

BACK HANGS THAT CANTILEVERS 4” OR MORE BEYOND A SOUND FRAMING MEMBER.

NOTE:

If rear back hangs are to be installed over drywall, use (2) 5/16” x 2” hex head lag

screws and make sure lag screws engage into solid structural lumber.

13