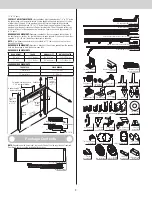

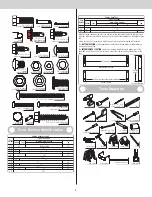

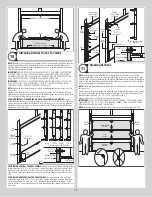

5/16”-18 x 3-3/4”

Eye bolt

Special

knot

3 Hole

clip

Rear

back

hang

Spring restraint

cable

Special

knot

5/16”-18 x 3-3/4”

Eye bolt

5/16”-18

Hex nut

Extension

spring

Horizontal track

5/16”-18

Hex nut

Horizontal track

5/16”-18

Hex nut

6”-8”

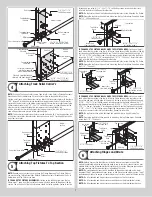

Attaching Spring Sheaves

19

Hook the sheave fork through the front loop of the extension spring and attach the sheave

fork to the rear cable lift sheave using (1) 3/8” - 16 x 1-1/4” hex head bolt and (1) 3/8” - 16

hex nut. Thread the counterbalance lift cable over the front cable lift sheave and around the

rear cable lift sheave and tie the special knot around the “horizontal angle” using a 3 hole

clip, as shown.

Insert one end of the large “S” hook into the “horizontal angle” with the 3 hole clip and the

other end into the second slot of the horizontal angle, as shown. Repeat for the other side.

IMPORTANT:

CLOSE “S” HOOKS AND EYE BOLTS WITH LOCKING PLIERS, TO PREVENT

SPRINGS FROM COMING LOOSE.

WARNING

FAILURE TO CLOSE “S” HOOKS AND EYE BOLTS CAN RESULT IN SEVER

OR FATAL INJURY IF SPRINGS COME LOOSE.

Rear

cable lift

sheave

Sheave fork

Horizontal track

Hook plate

This illustration shows doors featuring (2) pairs of extension springs

Counterbalance

lift cable

Counterbalance

lift cable

Spring restraint

cable

NOTE:

Some larger doors feature 2 pairs of extension springs. A spring restraint cable must

be installed through each spring.

Horizontal

track

Rear back hang

Extension

spring

3/8”-16 x 1-1/4”

Hex head bolt

3/8” - 16

Hex nut

Sheave fork

Extension spring

Rear cable

lift sheave

Sheave fork

Extension spring

Rear cable

lift sheave

3 Hole clip

Special

knot

Counterbalance

lift cable

“S”

Hook

“S”

Hook

Spring

restraint

cable

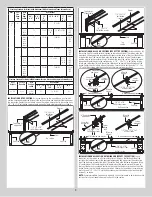

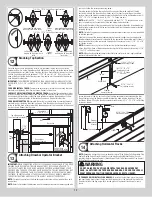

Counterbalance Lift Cable Adjustments

20

Adjust counterbalance lift cables to create about 1” to 2” (25 mm to 50 mm) of initial exten-

sion spring stretch, with the door in the fully opened position. Measure relaxed extension

spring length for your door height and verify with the chart below. Spring length must be the

same for both extension springs to allow even door balance. Carefully remove the locking

pliers from the horizontal track and lower the door into the closed position. Once the door is

closed, measure the extension spring length in tension for both sides. Using the chart, verify

the spring length in tension is correct with your door height.

NOTE:

It may be necessary to adjust spring length for proper door balance.

Door Height

Spring Length Relaxed (Door

Open)

Spring Length Extended

(Door Closed)

6’ 0”

25” (635 mm)

61” (1549 mm)

6’ 3”

25” (635 mm)

62-1/2” (1588 mm)

6’ 6”

25” (635 mm)

64” (1626 mm)

7’ 0”

25” (635 mm)

67” (1702 mm)

7’ 6”

27” (686 mm)

72” (1829 mm)

7’ 9”

27” (686 mm)

73-1/2” (1867 mm)

8’ 0”

27” (686 mm)

75” (1905 mm)

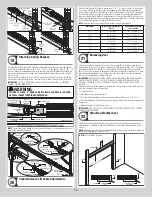

Balancing Door

21

Lift door and check its balance. If door rises off floor more than 2 ft. under spring tension

alone, reduce spring tension by adjusting extension spring length, moving the “S” hook back-

ward (towards the rear back hangs) to a different hole in the horizontal track. If the door is

hard to rise or drifts down on its own, adjust extension spring length by moving the “S” hook

forward (towards the header) to a different hole in the horizontal track. A poorly balanced

door can cause garage door operator problems.

IMPORTANT:

WHENEVER ADJUSTING EXTENSION SPRING LENGTH FOR DOOR BALANCE,

ALWAYS OPEN THE DOOR TO THE FULLY OPEN POSITION AND RETURN THE LOCKING

PLIERS, AS SHOWN IN F3 TO THE HORIZONTAL TRACKS BELOW THE BOTTOM TRACK

ROLLERS.

If the door still does not operate easily, raise the door into the open position, return the lock-

ing pliers, and recheck the following items:

1.) Is the door level?

2.) Are the flag angles level and plumb?

3.) Does the distance between the flag angles equal door width plus 3-3/8” to 3-1/2”?

4.) Do the counterbalance lift cables have equal tension? Adjust by re-tieing the special knot,

if necessary.

5.) Make sure door is not rubbing on jambs.

IMPORTANT:

IF DOOR STILL DOES NOT BALANCE PROPERLY, THEN CONTACT A TRAINED

DOOR SYSTEM TECHNICIAN.

Attaching Weather Seal

22

Permanently attach the weatherstrips on both door jambs and header. The weatherstrips

were temporarily attached in Preparing the Opening, in the pre-installation section of this

manual.

NOTE:

When permanently attaching the weatherstrips to the jambs, avoid pushing the weath-

erstrips too tightly against the face of door.

Weather seal

s

Nail

Weather

seal

Jamb

Weather seal

installed

Jamb

Header

Jamb

Nail

NOTE:

Door not shown for clarity.

15