10

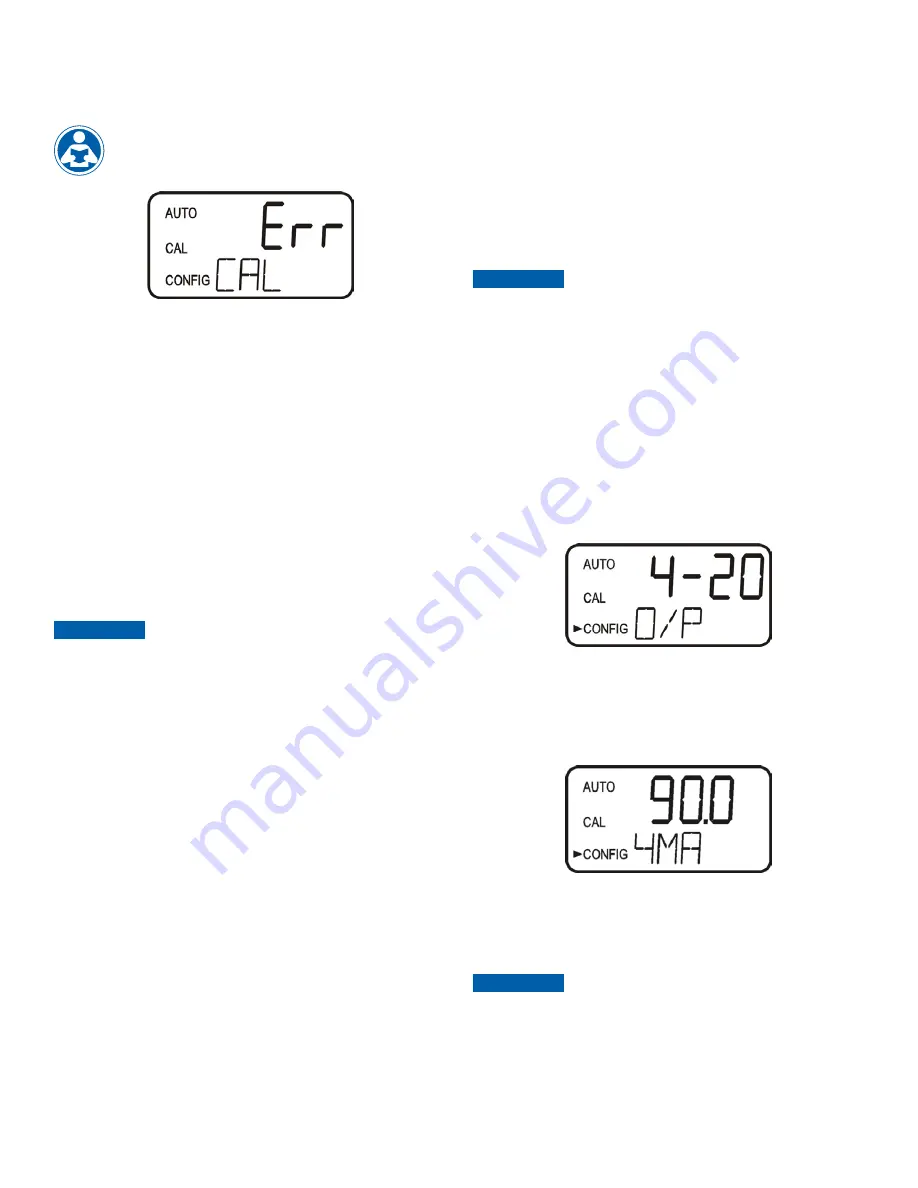

5.3 Calibration Error

If the screen shown below is displayed after the 100%T or 0 ABS

calibration, the internal diagnostics have determined that the calibration

fluid requires replacement or the flow through cuvette requires

replacement. Check, the calibration fluid and cuvette, then

recalibrate or restore the factory calibration see

6.1 Restoring

Factory Settings

. The instrument cannot be used without

performing one of these operations.

To recalibrate press the MODE key and start the calibration sequence

again. To restore the factory calibration, push and hold the

button.

Now push and release the

then release the

button.

6.0 Restore Factory Settings

6.1 Restoring Factory Settings

If the instrument is unable to perform a calibration due to a low lamp

output, bad calibration standard or a dirty cuvette, the instrument will

display

CAL

on the lower row of the display and

Err

on the upper

row. The operator has two choices to correct this problem or restore

the factory calibration. If the operator can determine whether a poor

calibration or a low lamp caused the problem, he/she can remedy

the problem and recalibrate. If all else fails, the operator may restore

the factory calibration and configuration settings by performing the

following operation. Push and hold the

button. Now push and

release the

then release the

button. Factory calibration and

factory configuration have now been restored.

Restoring the factory settings allows the use of the AccUView

LED with reduced accuracy. The original problem still exists and

must be determined and corrected before accurate operation

of the AccUView LED will be resumed. The AccUView LED will

always reset to %T and factory defaults after restoring.

NOTICE

7.0 Instrument Configuration

(CONFIG mode)

The instrument has been designed to provide the ability to customize

the instrument according to needs at any time during normal operation.

This mode has been split into sub-menus to facilitate instrument

configuration. This section describes how to use each of the sub-

menus to configure the instrument. While in the configuration mode,

the instrument has a time-out feature that automatically returns the

system operation to the

AUTO

mode after a fifteen (15) minute period.

Enter the

CONFIG

mode of the instrument by pressing the

MODE/EXIT

button

until the arrow beside CONFIG is illuminated, then press

the

button.

To exit the CONFIG mode, press the MODE/EXIT button.

NOTICE

7.1 Selecting the Output (O/P)

The first configuration selection is the O/P. The selections are:

1.

4-20

for the 4-20 mA output

2.

485

for the RS-485 and modbus

3.

OFF

if no outputs are required

Select the desired output by using the

and

buttons. Once the

desired output has been set, press the

button to accept it. The next

prompts will depend on the output selected.

7.2 Setting the 4-20 mA

If the 4-20 mA output was turned on, prompts to set the 4mA

(4MA)

and

20mA

(20MA)

%T or ABS limits levels will be displayed. There is also a

menu to adjust the error level

(ERLV)

. The first prompt will be the %T or

ABS limit assigned to the 4 mA output level.

7.2.1 Setting the 4 mA Level

Select the %T or ABS level to assign to the 4MA using the

and

buttons.

The factory setting is 90%T or.

Once the desired level has been set, press the

button to accept it.

The factory default setting for %T is 90%T and the for ABS is 0

The 4MA cannot be set higher than the 20 MA level.

NOTICE