61

VERSION 03/2018

ORDER NUMBER DOC 2369735

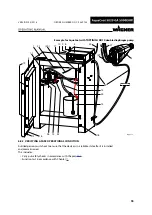

7.4.3 PRESSURE RELIEF/WORK INTERRUPTION

The pressure must always be relieved:

– after the spraying tasks are finished.

– Before servicing or repairing the spraying system.

– Before carrying out cleaning tasks on the spraying system.

– Before moving the spraying system to another location.

– Before something must be checked on the spraying system.

– Before the nozzle is removed from the spray gun.

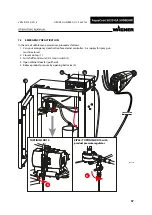

Procedure

1. Close the spray gun.

2. Switch off control unit.

3. Close the compressed air supply.

4. Open cabinet door (pull hard).

5. Place grounded metal tank for return product under the return tube.

6. Open the return valve slowly.

7. When no further overpressure is detected, close the return valve.

8. Using the external control air (red), open the nozzle of the spray gun until no more

pressure is applied.

9. Secure the spray gun against actuation Remove the external control air hose (red).

10. Close cabinet door again.

In the case of a clogged nozzle, proceed in accordance with Chapters

and

.