53

VERSION 03/2018

ORDER NUMBER DOC 2369735

6.8

COMMISSIONING

6.8.1 PREPARATION

Before every start-up, the following points should be observed as laid down in the operating

manual:

– For underframe with rolls (option): Lock all four swivel castors with the footbrake.

– Only metal tanks may be used for product and flushing agents, no plastic tanks.

– Check the permissible pressures.

– Check all connections for leaks.

– Check hoses for damage in accordance with Chapter

.

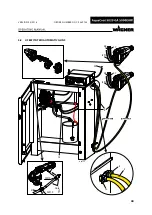

Connect the compressed air

– Connect the AquaCoat system to the compressed air source (8).

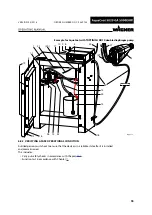

Fill the devices with flushing agent

The devices are tested during manufacturing with oil or other fluids. Possible residues

must be flushed out of the circuits with a solvent (flushing agent) before commissioning.

– Fill the empty device with flushing agent in accordance with Chapter

pump's

operating manual. Suction the product: Increase the air pressure gradually until the

pump starts. Do not let the pump run too quickly while suctioning.

NOTICE

Impurities in the spraying system!

Spray gun blockage, products harden in the spraying system.

Flush the spray gun and paint supply with a suitable flushing agent before commissioning.

6.8.2 COMMISSIONING

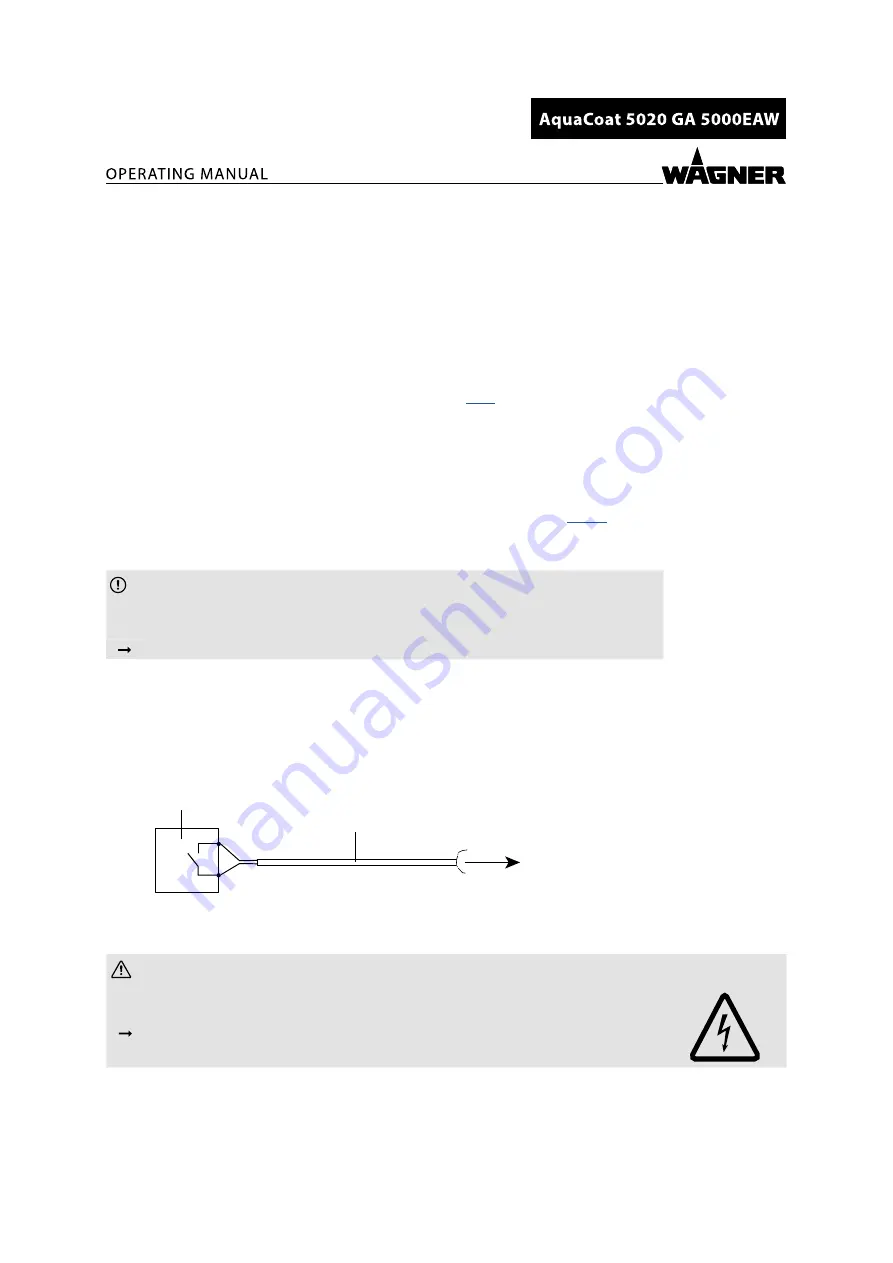

6.8.2.1 CONNECT CONTROL CABLE

– Connect the external control cable (23) 15 m; 49.2 ft (order number 2316194) to external,

floating switch.

– The switch is used to switch the high voltage in the cabinet on and off.

B_02904

23

Cabinet

Switch floating

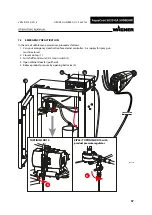

6.8.2.2 CHECK THE UNIT FOR LEAKS

CAUTION

Electrical discharge when using coated product tanks!

Risk of injury; product charge not optimal.

Ensure that the metal part of the tank is connected to the potential equalization line

(e.g., remove coating from around the connection point).