46

Note

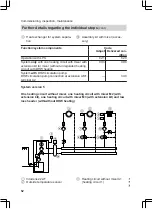

Operate the appliance with uncontaminated combustion air to prevent operating

faults and damage.

CO

2

or O

2

content

■ The CO

2

content must be within the following limits (upper and lower output):

– 7.7 to 9.2 % for natural gas E and LL

– 9.3 to 10.9 % for LPG P

■ For all gas types, the O

2

content must be between 4.4 % and 6.9 %.

If the actual CO

2

or O

2

values lie outside their respective ranges, proceed with the

following steps:

■ Checking the balanced flue system for tightness, see page 33.

■ Checking the ionisation electrode and connecting cable, see page 36.

Note

During commissioning, the combustion controller carries out an automatic calibration.

Only test the emissions approx. 30 s after the burner has started.

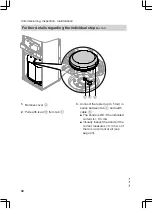

1.

Connect a flue gas analyser at flue

gas aperture

A

on the boiler flue

connection.

2.

Open the gas shut-off valve, start the

boiler and create a heat demand.

3.

Select the lower output (see

page 47).

4.

Check the CO

2

content. Should the

actual value deviate from the above

ranges by more than 1 %, implement

steps from page 45.

5.

Enter actual values into the service

report.

6.

Select the upper output (see

page 47).

7.

Check the CO

2

content. Should the

actual value deviate from the above

ranges by more than 1 %, implement

steps from page 45.

8.

After testing, press

OK

.

9.

Enter actual values into the service

report.

Commissioning, inspection, maintenance

Further details regarding the individual steps

(cont.)

5457 552 GB

Summary of Contents for FS2B

Page 163: ...163 5457 552 GB ...