32

5.

Start the boiler.

Note

During commissioning, the boiler can

enter a fault state because of airlocks

in the gas line. After approx. 5 s,

press the reset button R (see operat-

ing instructions) to reset the burner.

6.

Check the supply (flow) pressure.

Set value:

■ Natural gas: 20 mbar

■ LPG: 50 mbar

Note

Use suitable test equipment with a

resolution of at least 0.1 mbar to

measure the supply pressure.

7.

Record the actual value in the service

report on page 157.

Take the action shown in the follow-

ing table.

8.

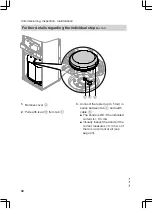

Shut down the boiler, close the gas

shut-off valve, remove the pressure

gauge and close test nipple

A

with

the screw.

9.

Open the gas shut-off valve and start

the boiler.

Danger

Gas escaping from the test

nipple leads to a risk of explo-

sions.

Check test nipple

A

for tight-

ness.

Supply (flow) pres-

sure for natural

gas

Supply (flow)

pressure for LPG

Measures

below 17.4 mbar

below 42.5 mbar

Do not start the boiler. Notify your gas

supply utility or LPG supplier.

17.4 to 25 mbar

42.5 to 57.5 mbar

Start the boiler.

above 25 mbar

above 57.5 mbar

Install a separate gas pressure governor

upstream of the system and regulate the

pre-charge pressure to 20 mbar for natu-

ral gas or 50 mbar for LPG. Notify your

gas supply utility or LPG supplier.

Setting the maximum output

You can limit the maximum output for

heating operation

. The limit is set via the

modulation range. The max. adjustable heating output is limited upwards by the boiler

coding card.

Weather-compensated control unit:

1.

Press

OK

and

å

simultaneously

for approx. 4 s.

2. "Service functions"

3. "Max. output"

Commissioning, inspection, maintenance

Further details regarding the individual steps

(cont.)

5457 552 GB

Summary of Contents for FS2B

Page 163: ...163 5457 552 GB ...