45

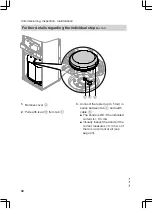

Checking the pre-charge pressure and the DHW expansion ves-

sel (if installed)

A

1.

Check the static pressure of the DHW

line downstream of the pressure

reducer and adjust if required. Set

value: max. 3.0 bar

2.

Close the on-site shut-off valve in the

cold water line.

3.

Turn lever on valve

A

to the "front"

position.

4.

Check the pre-charge pressure of the

DHW expansion vessel and adjust if

required. Set value: Static pressure

minus 0.2 bar

5.

Turn lever on valve

A

back to the

"l.h." position and open the on-site

shut-off valve in the cold water line.

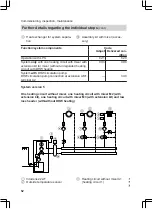

Checking all gas equipment for tightness at operating pressure

Danger

Escaping gas leads to a risk of

explosion.

Check gas equipment for tight-

ness.

Note

For the tightness test, use only suitable

and approved leak detecting agents (EN

14291) and devices. Leak detecting

agents with unsuitable constituents (e.g.

nitrites, sulphides) can lead to material

damage.

Remove residues of the leak detecting

agent after testing.

Checking the combustion quality

The electronic combustion controller automatically ensures an optimum combustion

quality. Only the combustion values need to be checked during commissioning and

maintenance. For this, check the CO

2

or O

2

content. For a description of the electronic

combustion controller functions, see page 144.

Commissioning, inspection, maintenance

Further details regarding the individual steps

(cont.)

5457 552 GB

Service

Summary of Contents for FS2B

Page 163: ...163 5457 552 GB ...